In the field of agriculture, the quality of fertilizer is crucial, and fertilizer testing is a key link to ensure its quality. Among them, there is a close connection with the fertilizer production machine.

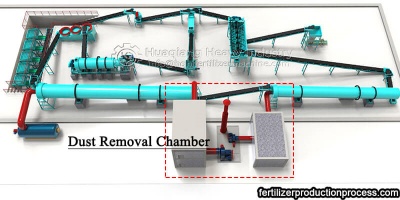

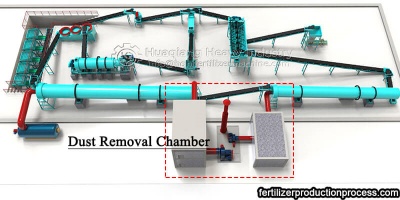

Fertilizer production machine is the "birth room" of fertilizer. From the mixing of raw materials to the molding of pellets, every machine contributes to the production of fertilizer. However, even the most advanced fertilizer production machines require rigorous testing to ensure the quality of the product.

In the fertilizer production line, the first is the detection of raw materials. Before the raw materials enter the mixing equipment, professional testing equipment will test the purity and nutrient content of various raw materials, such as nitrogen sources, phosphorus sources, potassium sources, etc. This is like a "qualification review" for the raw materials that are going to participate in the "chemical reaction festival", and only the raw materials that meet the criteria can enter the next stage.

Mixing equipment is one of the key machines in fertilizer production. The fertilizer production machine mixes various raw materials in a certain proportion. During this process, real-time inspection equipment monitors the uniformity of the mixture. If the mixture is not uniform, it may lead to uneven distribution of fertilizer nutrients and affect the fertilization effect.

The granulation equipment processes the mixed material into pellets. After the granulation is completed, the testing equipment will detect the physical indicators such as the size and strength of the particles. For example, through a specific screen to screen out the size of the particles that do not meet the requirements, or through a pressure test equipment to detect the compressive strength of the particles.

The drying equipment also needs to be tested while removing the moisture of fertilizer particles. The testing equipment will monitor the temperature, humidity and other parameters of the fertilizer during the drying process to ensure that the drying effect is optimal, which will not cause the fertilizer to caking due to insufficient drying, and will not affect the fertilizer nutrients due to excessive drying.

Moreover, in the fertilizer testing process, the nutrient content of the fertilizer will be accurately analyzed. Advanced chemical analysis instruments are used to detect whether the content of nitrogen, phosphorus, potassium and various trace elements in fertilizers meets the standards of product labeling.

In short, fertilizer testing is an important line of defense to ensure fertilizer quality, and it complements fertilizer production machines. Through the detection of all aspects of fertilizer production, combined with the adjustment of the operating parameters of the fertilizer production machine, it is possible to produce high-quality fertilizers that meet the needs of agricultural production, and lay a solid foundation for the robust growth of crops.