Problems that should be considered when choosing to buy organic fertilizer equipment

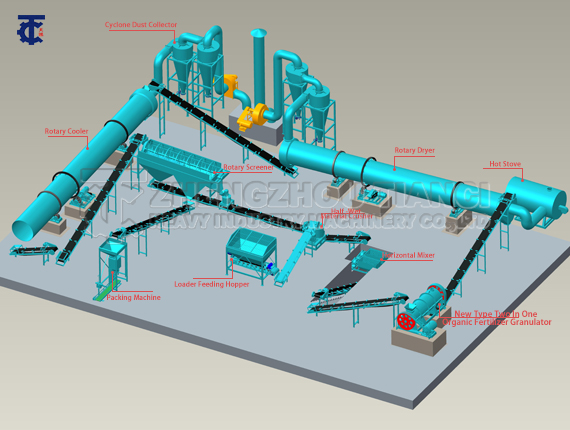

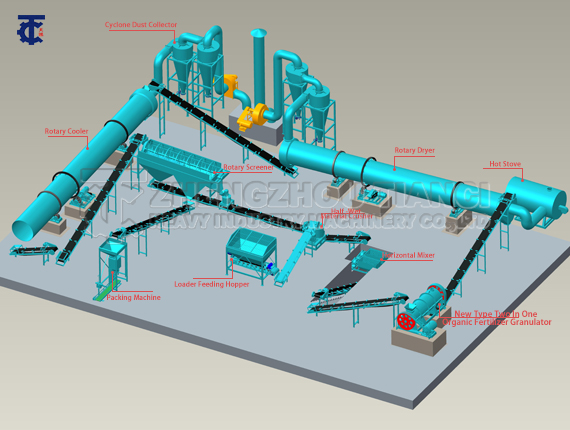

The processing flow of the organic fertilizer production line: raw material treatment → harmless treatment → mixed ingredients → granulation → cooling and screening → metering and sealing → finished product storage. When choosing to buy organic fertilizer equipment, you should first consider the needs of your own factory. After doing market research, you must determine the scale of fertilizer production you need, and determine the appropriate production scale based on market prospects and raw material supply. Then understand the organic fertilizer equipment for matching selection.

1. Determine the output size of the complete set of organic fertilizer equipment: for example, how many tons of annual output, or how many tons per hour, some factories can run for 24 hours, while others can only run for 8 hours, so it is necessary to specify the hourly output. output, and matching equipment is more reasonable.

2. Determine the shape of the particles: powder, column, oblate or standard circle. Commonly used granulators are: disc granulator, stirring granulator, double roller press granulator, flat die granulator, ring film granulator. The selection of the granulator should be based on the local fertilizer sales market, the equipment is different, and the price is also different.

3. The distribution level determines the cost of organic fertilizer equipment. Determine the configuration of the equipment: Different configuration levels, different equipment prices, and different labor volumes.

4. Determine the type of fertilizer production. Generally, the types of organic fertilizers are divided into four types, pure organic fertilizers, organic or inorganic compound fertilizers, bio-organic fertilizers, compound microbial fertilizers, and different types of equipment.

6. Determine the main types of organic raw materials: the common organic raw materials are chicken manure, pig manure, cow manure, sheep manure, straw, medicinal residue, furfural residue, humic acid, pool mud, municipal sewage treatment plant sludge, etc. The selection of different raw materials and equipment is also slightly different.