2025-07-04

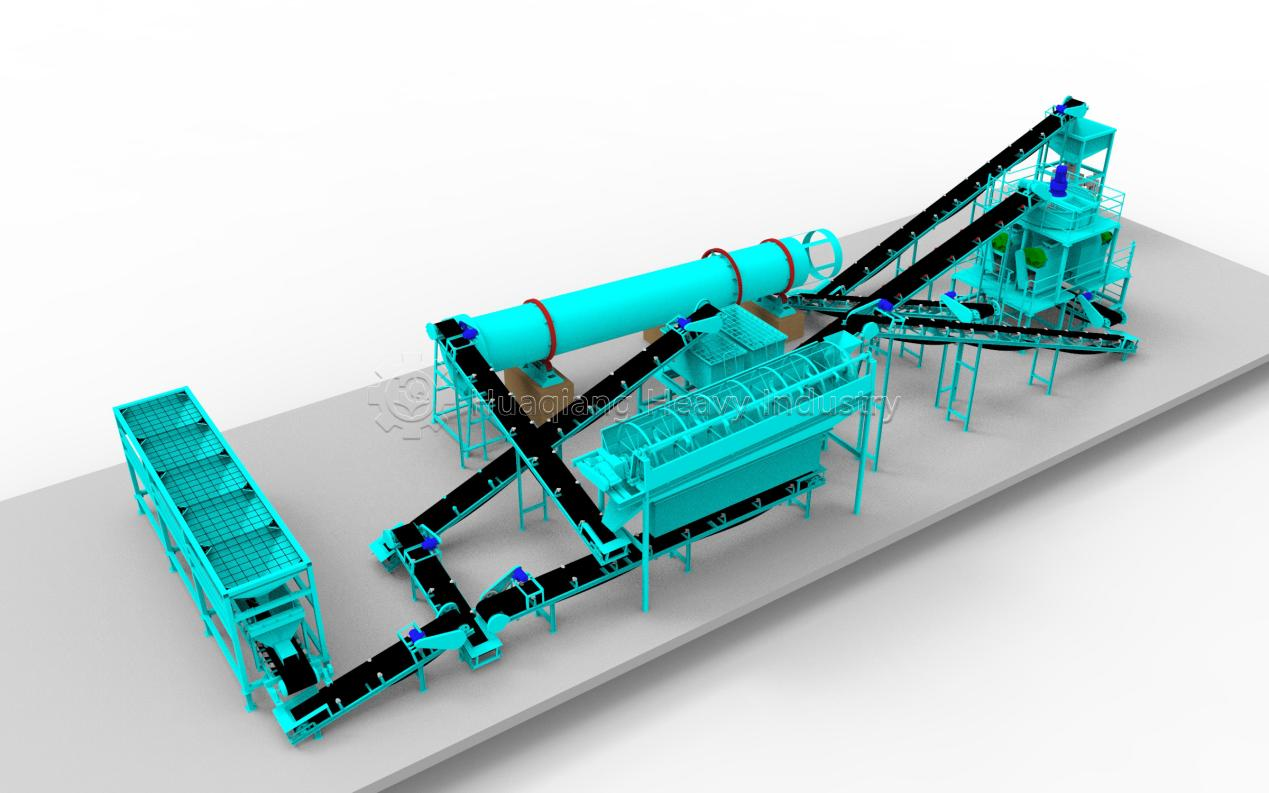

"Fertilizer granulation" is the core process in fertilizer production, while "fertilizer production line" refers to the complete system including raw material processing, mixing, granulation, drying, cooling, screening and packaging. The granulation process acts like the heart of the production line, with its efficiency directly affecting the entire system's output capacity.

The "fertilizer granulator" is the key equipment that transforms powdered materials into uniform granules. Different types of granulators (such as rotary drum, disc, extrusion types) suit different raw materials and production needs. The granulator's performance parameters (like capacity, granulation rate, energy consumption) directly determine the overall efficiency of the production line.

1. Optimize Raw Material Pretreatment: Control moisture content between 12-15% and particle size to 40-80 mesh, which can significantly improve granulation rate[1].

2. Precise Adjustment of Equipment Parameters: Adjust granulator angle (typically 35-55° for disc type), rotation speed (typically 10-30rpm for drum type) and filling rate (usually 30-50%) according to material characteristics.

3. Scientific Binder Formulation: Adding proper amount (usually 1-3%) of specialized binder can improve granule strength and reduce recycle material.

4. Application of Intelligent Control Systems: Using PLC automatic control systems to monitor and adjust key parameters in real time can improve efficiency by 15-20%.

5. Preventive Maintenance Program: Regular inspection of mold wear, bearing lubrication and transmission system can reduce unexpected downtime.

1. Balanced Process Design: Ensure granulator capacity matches with preceding and following processes (like drying, cooling) to avoid bottleneck effects.

2. Heat Energy Recovery: Heat recovery systems in drying section can reduce energy consumption by 20-30%.

3. Automated Material Handling: Adopt automatic conveying, measuring and packaging equipment to reduce manual intervention and material loss.

4. Data-Driven Optimization: Collect and analyze production data through MES systems for continuous process improvement.