When the water content is between 20% and 40%, the fertilizer granulator can make the material into solid spherical particles, which greatly saves energy and equipment and improves efficiency. During the drying process, its special polishing and mixing round functions make the particles smoother. Roller granulator suitable for granulation of dry powder fertilizer. Organic fertilizer granulator is suitable for granulating pure organic fertilizer or organic-inorganic fertilizer.

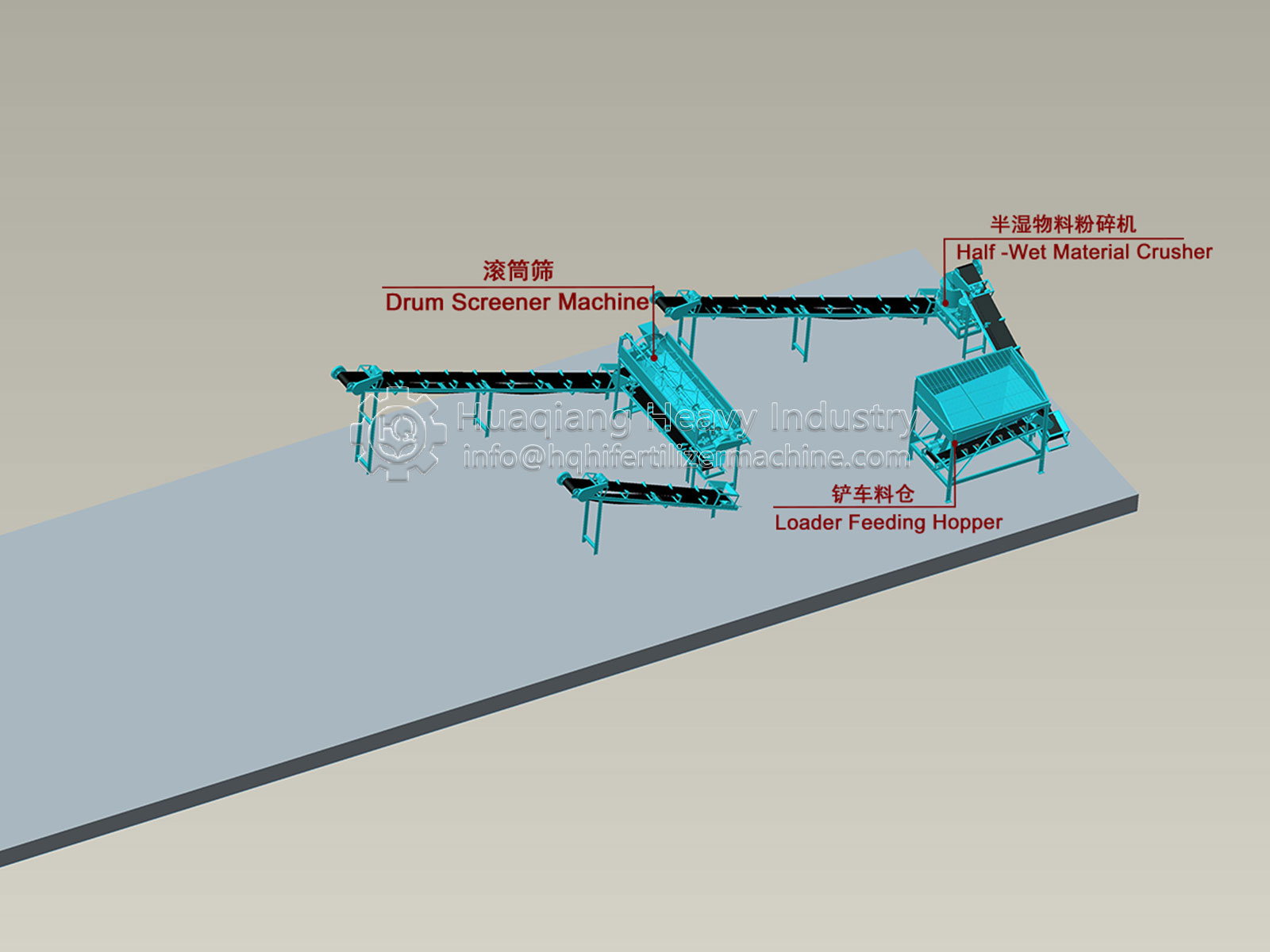

1. Crush

After fermentation for 1 day, the material will be crushed. Drying, crushing and screening of fermented organics.

2. Formulation and mixing

According to the formula, automatically prepare and mix nitrogen, phosphorus, potassium and fermentation materials, and transport them to the fertilizer granulator for granulation. According to different product mix organic and inorganic material formula, and fully mix in the mixer.

3. Granulation

The production of bio-fertilizers is mainly based on organic matter, with more cellulose and poor molding conditions. And because of the addition of live bacteria with the function of making fertilizer, the production process should not be exposed to high temperatures. Therefore, for the production of organic biological fertilizers, a new type of organic fertilizer granulator and wet granulation process are used. For NPK compound fertilizer, disc granulator machine, double roller extrusion granulator, or rotary drum granulator should be selected according to the special effects of raw materials. After granulation, the material is sent to the dryer through a belt conveyor for drying. The particle size is 3.0-4.0mm, and the granulation rate is greater than 80%.

4. Drying

In the production process of biological fertilizers, not only the water content of the formed particles generally exceeds the index, which requires low temperature spray drying and other means, but also the water content of the organic matter after fermentation is 30% to 40%, the particles are generally 15% to 20%, and the fertilizer The quality index requires that the water content is less than 14%, so the material needs to be dried. Therefore, the drying part is an indispensable process in the production process of biological fertilizers, which directly affects the yield, quality and energy consumption. It is very important to choose the type and specification of the dryer and control the process conditions.

5. Cooling

The dried material will be transferred to the cooler to be cooled by the belt conveyor. The cooling process is mainly to use the blower to send natural air through the pipeline into the cooling machine to cool the material.

6. Screening and packaging

The cooled material will be transferred to the drum screening machine for screening: the crushed large-particle materials and the sifted powder will be returned to the granulator through the return conveyor to be re-granulated, and the qualified fertilizer particles will be transported to the automatic packaging system for package.