Advantages of large granular urea fertilizer

1. The content of large granular urea dust is low and the granular strength is higher. Because the granular strength of large granular urea is higher, it is not easy to break and agglomerate, and it is more convenient to transport. Moreover, the size of urea particles is different,

NPK fertilizer production process is different, and the dust content of large particles is lower.

2. The content of biuret in large granules was lower. Urine evaporation is required to concentrate to 95%-96% in the production of large granular urea, which effectively reduces the production of biuret and effectively reduces the damage of urea to crops after farmers use.

3. The fertilizer effect of big granular is more lasting. Because of its small surface area and slow dissolution rate, the fertilizer efficiency of large granular urea in soil is more persistent.

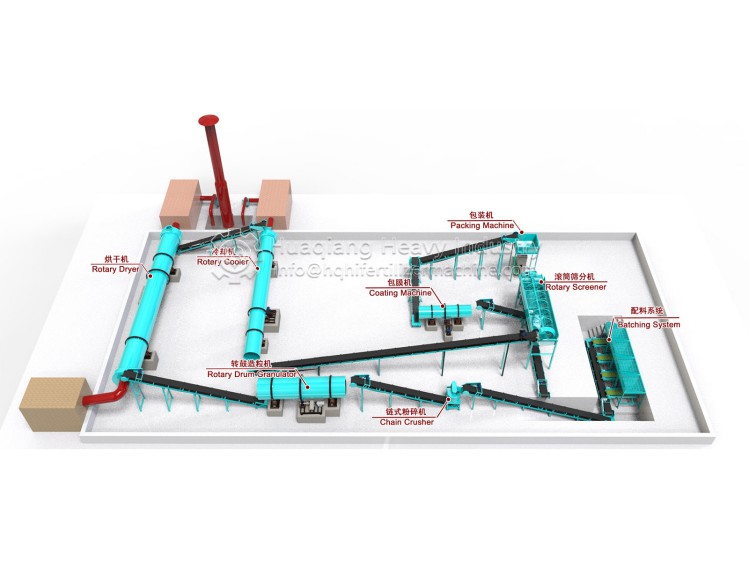

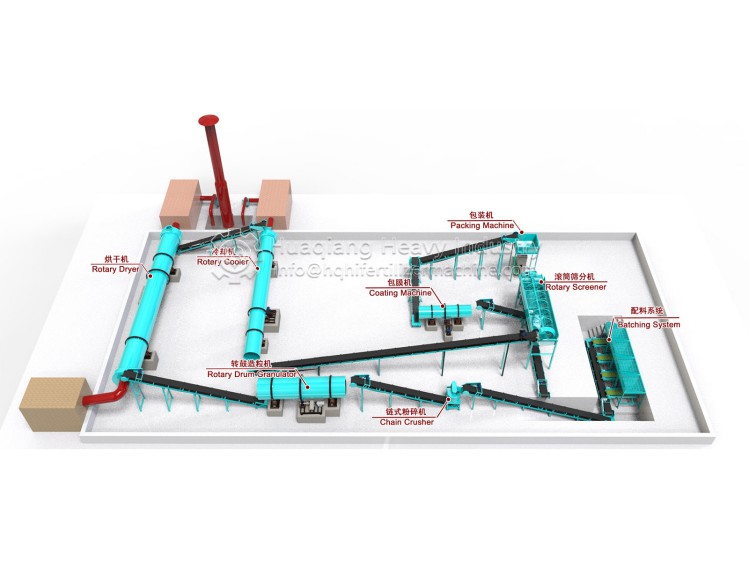

Brief introduction of large granular urea fertilizer production process

1) Some fine granular urea is metered and transported to the rotary drum granulator.

2) Continuous addition of some urea to the urea melter provides heat through a steam (heat conducting oil) boiler, which melts urea into a liquid state (or draws branch pipes from the pipes of the granulator).

3) The urea slurry is atomized and sprayed onto the material curtain in the

rotary drum granulator through a special pump after pressurization, so that the fine urea evenly forms a thick curtain on the side of the granulator. The drum granulator has an inclined angle. With the continuous rotation of the granulator, the fine material of the bed moves forward continuously, and the continuous coating will grow to the desired grain. Granular range products.

4) Urea fertilizer is transported to the rotary cooler, and the cooling particles are at 40-50 C.

5) Fertilizer is transported to the finished product screening machine, and the fine particles after sorting are directly returned to the rotary drum granulator to participate in coating and pelletizing, and the large particles after sorting are crushed by the urea crusher and then returned to the drum granulator.

6) The qualified products after sorting are put into automatic packaging scale, weighed and packaged, and stored in storage.

7) In order to reduce environmental pollution, urea dust should be cleaned by a dust collector; after washing, the concentration of dilute urea solution reaches 30-40%, it is sent to the urea evaporation system, and the air dust content is less than 30 mg/m.