A fertilizer granulation production line is not a fixed equipment as we imagine, but it needs to be determined according to the site and materials. For example, chicken manure has a lot of moisture, so the moisture must be reduced during fermentation. Straw and corncob can be added after being crushed by straw crusher, otherwise, organic fertilizer particles cannot be made. But the sheep dung is relatively dry, when the fermentation time controls the moisture, does not need to add the straw and so on directly may granulate. Different fertilizer production process, drum granulation equipment used is not the same.

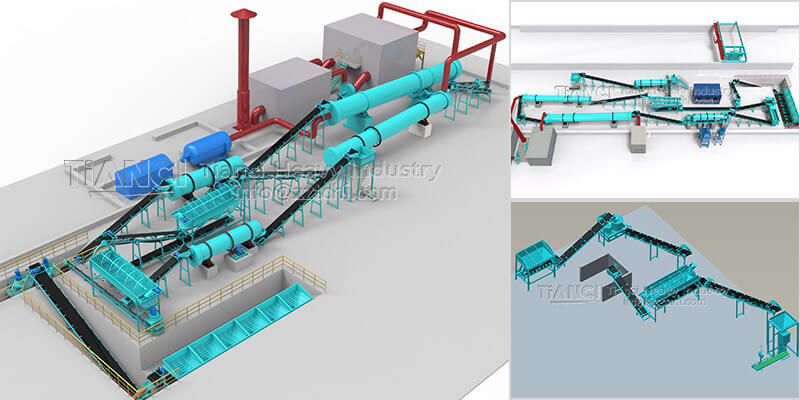

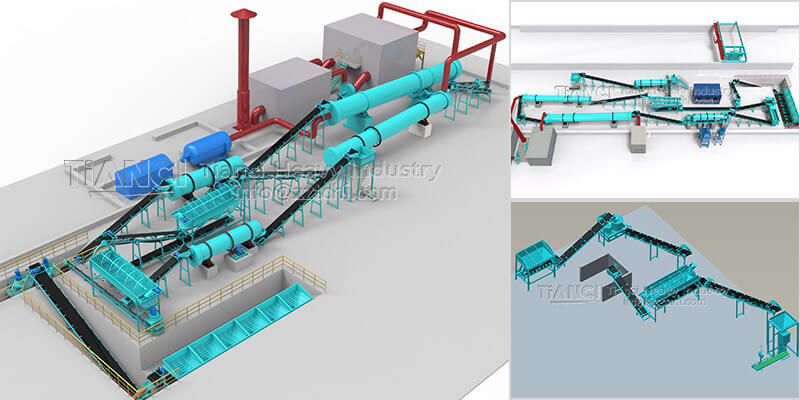

Organic fertilizer production line is to process animal manure into granular organic fertilizer through a series of treatment, including fermentation, crushing, granulation, drying, cooling, screening and coating.

NPK fertilizer manufacturing process is to pulverize different fertilizers containing nitrogen, phosphorus and potassium, mix them according to the formula ratio, and then granulate, then dry and cool, screen out suitable granules, and package them.