Everyone knows that the digestive ability of chickens is very weak, so that chicken manure contains high nutritional trace elements. Dry chicken manure contains 50% organic matter, 3.2% nitrogen, 3.1% phosphorus (calculated as P2O5), and potassium (calculated as K2O). ) 2.4%, rich in nutrients and a lot of protein, it is an excellent raw material for making organic fertilizer. The key point of making good organic fertilizer is the fermentation effect of raw materials, so how to make organic fertilizer from chicken manure?

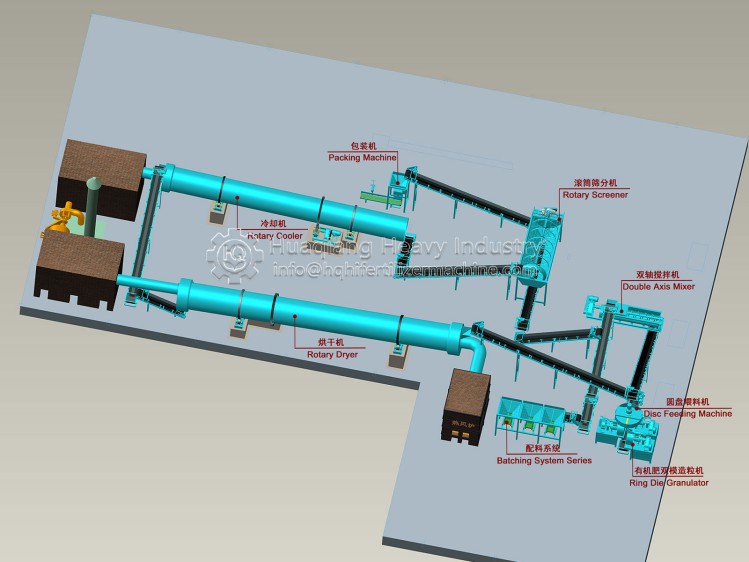

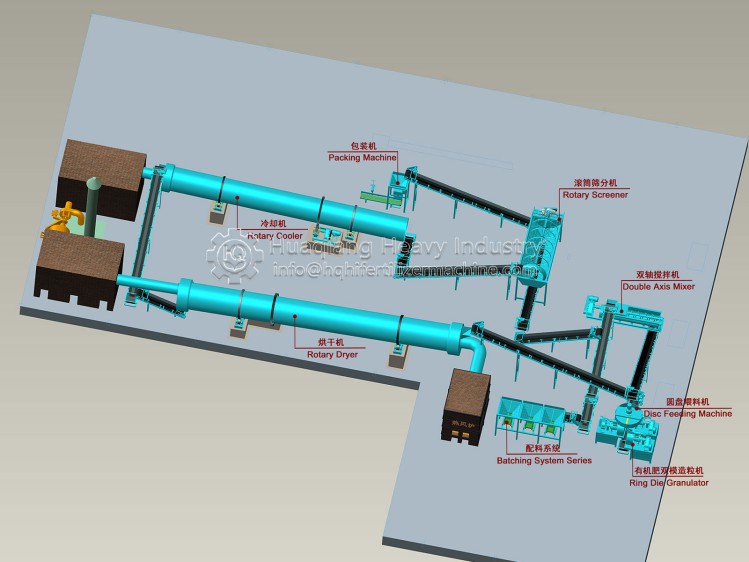

The drum granulation production line is a commonly used chicken manure organic fertilizer granulation production line. The fertilizer granulator used in this

drum granulation production line is a drum granulation machine. The drum granulator can be used for the granulation of organic fertilizer or compound fertilizer.

Main technologies for composting chicken manure:

Chicken manure composting fermentation mainly uses biological action combined with advanced mechanical technology to effectively treat chicken manure. The commonly used process is aerobic fermentation. Using aerobic fermentation, chicken manure composting has a fast temperature rise, a high fermentation temperature and a short maturity cycle. Due to its high fermentation temperature, it can effectively kill eggs, germs, plant seeds, etc. in chicken manure. Under effective mechanical stirring, its drying effect is also very significant. At present, the commonly used compost fermentation processes in the industry mainly include stack compost fermentation process and trough aerobic fermentation process.

The

equipments required for biofertilizer production is similar to the Chicken Manure Organic Fertilizer Production Line.

In actual production, the temperature of the fermentation tank will be affected by the temperature season to a certain extent. In summer, the temperature in the workshop is above 30℃, and the fermentation temperature can reach 60~65℃, or even over 65℃. It can be stirred at intervals of 1 hour, which is conducive to the aerobic fermentation of microorganisms and the drying of materials. In winter, when the temperature in the workshop is below 10°C, the fermentation temperature can only reach 45-55°C. Because the stirring effect will take away a part of the heat, it can be stirred at an interval of 4 hours to help maintain high temperature conditions. We have the most professional

fertilizer manufacturing equipment, welcome to buy!