The spatial layout of organic fertilizer fermentation equipment is closely related to the size of infrastructure area and investment. Reasonable layout of organic fertilizer fermentation equipment can reduce investment, effectively utilize production space, and maximize the effect with the least cost. The following will explain how to do a good spatial layout of organic fertilizer fermentation equipment.

1.The influence of raw materials on organic fertilizer production process and plant design.

Due to the different raw materials, the production process and fertilizer production machine are affected, and most of the organic fertilizer raw materials are polluted. In one case, for the pretreatment process of raw materials, the manufacturer can directly preprocess the raw materials in the farm or growers, and then store and transport them to the manufacturer in a sealed manner; the other situation is to collect raw materials directly from the growers and farms. The treated waste is pretreated in the plant area. These two methods have a direct impact on the area construction of the processing zone.

2.The influencing factors of fermentation technology.

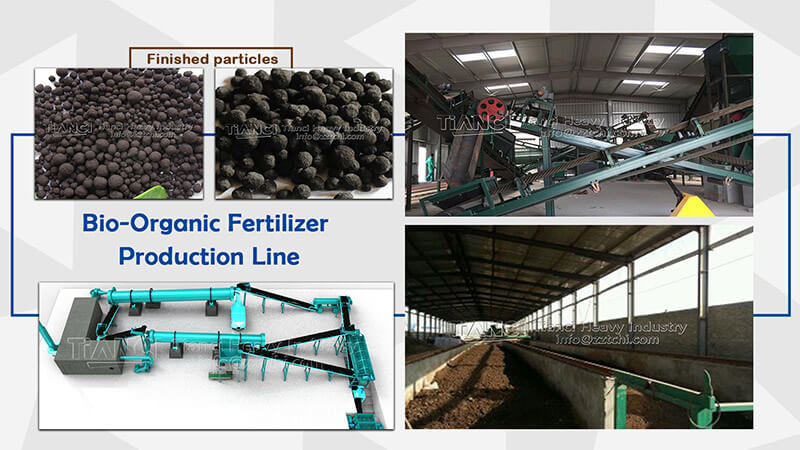

The fermentation process should be based on the amount of materials. Currently, aerobic fermentation is more in line with the production standards. The fermentation cycle includes two parts: fermentation maturity and secondary aging. As far as possible, tank fermentation or strip fermentation should be selected for organic fertilizer fermentation. Under the same production capacity requirements of the two, the strip fermentation occupies more plant area.

Another factor affecting the fermentation process is the fermentation equipment used. In tank fermentation, the mobile crane is often used for multi tank fermentation, and the material is directly moved to the outlet in the process of turning and throwing. The second aging stage can be transferred to the fermentation tank, so that continuous fermentation can be realized,; However, it is inconvenient to transfer the raw materials due to walking composter or tipping and throwing machine. The secondary aging process is often in situ aging, which affects the fermentation cycle.

3. The influence of the process in the later deep processing stage.

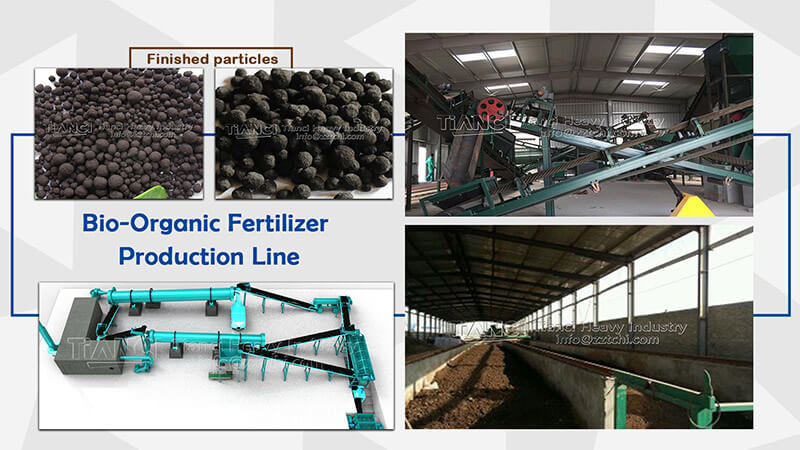

The late processing technology of organic fertilizer production line equipment is divided into powdery organic fertilizer production line technology and granular organic fertilizer production line technology. The occupied area and equipment capital investment are very different. The granular organic fertilizer production line is more complex, including disc granulator machine, roller granulator, flat die pellet mill, rotary drum granulator and other equipment and subsequent processes.