There are many kinds of organic fertilizer products, among which microbial organic fertilizer is a relatively high-end fertilizer. The production process of using animal manure to process microbial organic fertilizer with

fertilizer manufacturing equipment is also slightly different than other fertilizer production, and its purpose is to protect the microbial bacteria in the fertilizer production process. Here this article briefly describes the production process of various raw materials to produce this fertilizer.

Production process of chicken manure organic fertilizer

Chicken manure has high moisture content, and its production process is applicable to other poultry manure treatments. In the first stage of fermentation, it is not feasible to ferment materials with excessive moisture content, which requires dehydration. The chicken manure dehydrator can be used to separate the solid manure from wet and dry, and then ferment and decompose.

Cow manure organic fertilizer production process

Cow dung is relatively more suitable for its moisture content. Of course, if some cow dung is mixed with urine, it needs to be dehydrated first. Due to the different foods being fed, the digestibility is also different. Cow manure contains more fiber components, so the fermentation cycle can be slightly longer during fermentation, making it completely decomposed.

Production process of biogas residue organic fertilizer

Biogas residue is the residue left after the production of biogas from livestock manure, and it is a good raw material for the production of microbial organic fertilizer. Although anaerobic fermentation has been carried out, in order to achieve complete harmlessness, it is best to continue to enter the tank for aerobic fermentation. The biogas residue extracted from the biogas digester has high moisture content, which is the same as chicken manure. It needs to be dehydrated and then fermented.

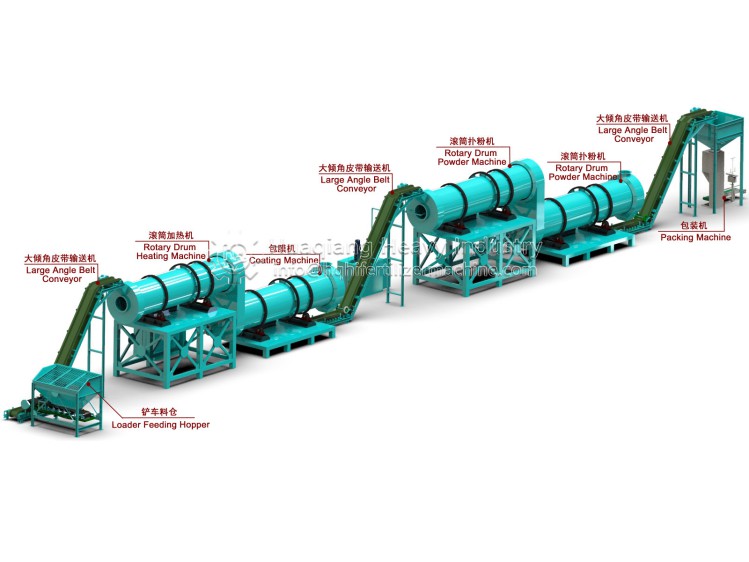

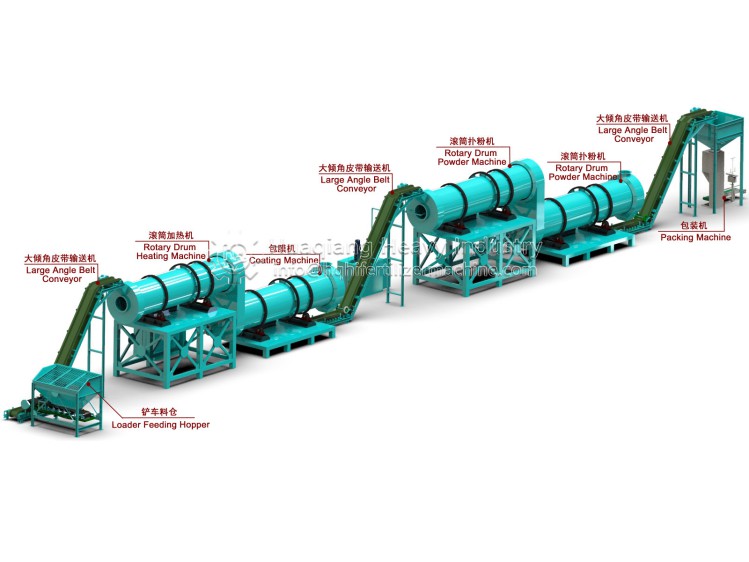

The main link in the organic fertilizer production process is the fermentation of organic fertilizer raw materials. The subsequent processes are all deep processing to commercialize them. For example, the fermented materials can be made into powder organic fertilizer products, or they can be processed into granules using an organic fertilizer granulator. Fertilizer products.

Microbial organic fertilizer products are added with microbial bacteria on the basis of ordinary organic fertilizers. Because these bacteria have a limit on the survival temperature, when producing granular biological fertilizers, in order to avoid being killed by high temperature in the dryer, Will adopt low temperature drying mode. Or adding bacteria in the coating machine stage, these are better solutions.

We produce different kinds of

equipments required for biofertilizer production, welcome to inquiry.