Organic fertilizer granulation production line is a kind of manure of chicken, sheep, pig as main raw materials, adding a certain amount of nitrogen fertilizer, phosphate fertilizer, potash fertilizer, magnesium sulfate, ferrous sulfate and other substances, fermenting with rice bran, yeast, soybean meal and sugar for a certain period of time As a biological bacteria, under the action of sulfuric acid, mixed fermentation equipment to make biological fertilizer.

Process flow of complete

equipments required for biofertilizer production:

1. Fermentation: Collect poultry manure and urine, mix it with hay and rotten silage, etc. to make compost, and let it ferment. In the fermentation process, the pile turning machine is used to fully ferment the cow dung, which can only be achieved by turning the pile in time and evenly.

2. Ingredients crushing and mixing: use the ingredient bin to mix the composted materials, N, P, K and other inorganic fertilizers, and other additives and other raw materials, and pass the material crusher and horizontal mixer in proportion to crush, proportion and mix.

3. Granulation: A new type of organic fertilizer

drum granulation machine is used to granulate the material.

4. Screening and material return system: The granular materials output from the granulating forming system have different particle sizes and need to be screened and classified.

5. Drying: Use an organic fertilizer dryer to further remove moisture from the sieved particles to meet the standard requirements of organic fertilizer moisture content.

6. Cooling: Use a cooler to cool the granular materials, which is helpful for the storage and quality of the granules.

7. Packing: The granular materials cooled by the organic fertilizer equipment are transported into the finished product warehouse through the bucket elevator. Granular materials can be quantitatively weighed and packaged through automatic packaging scales

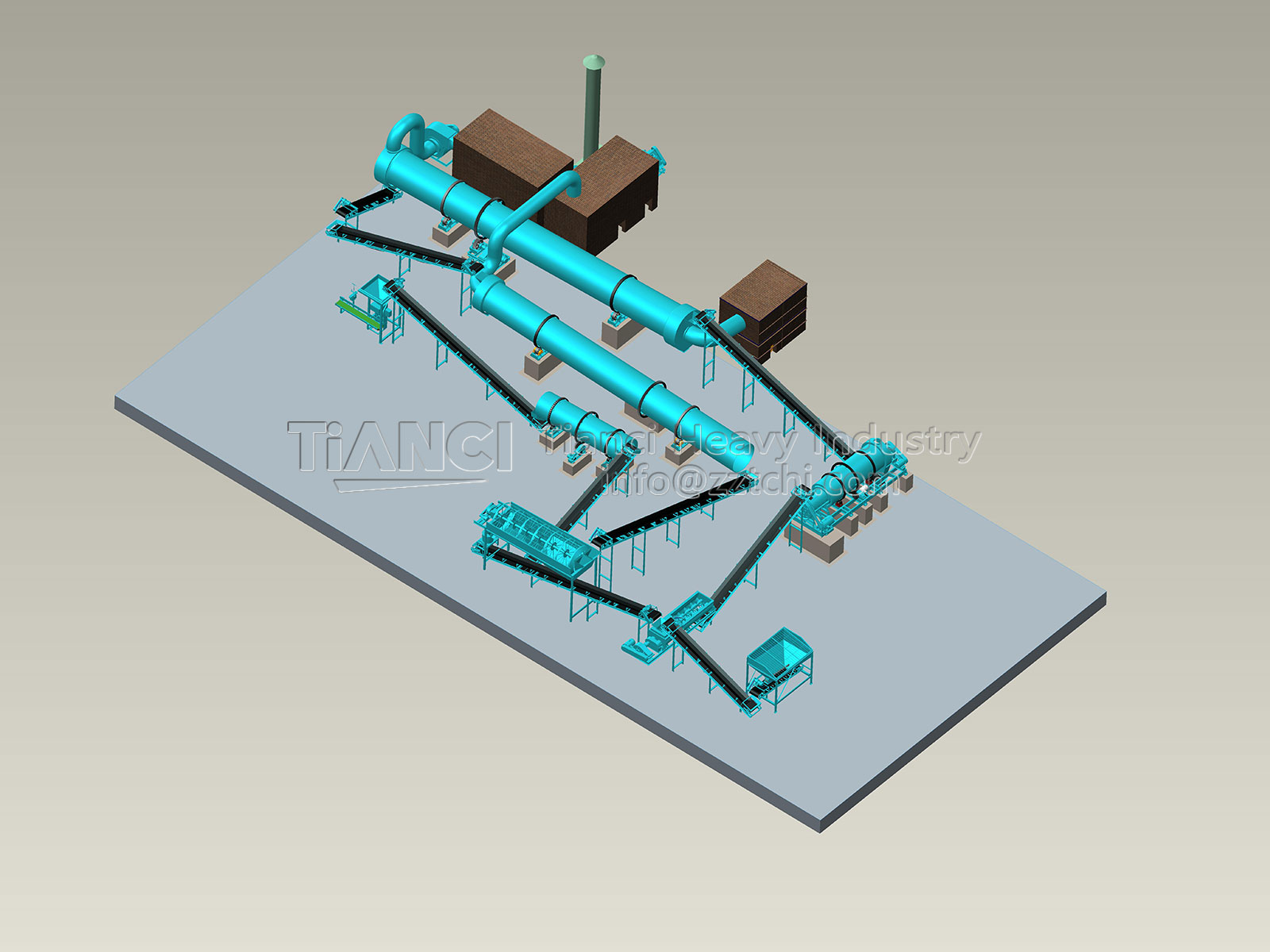

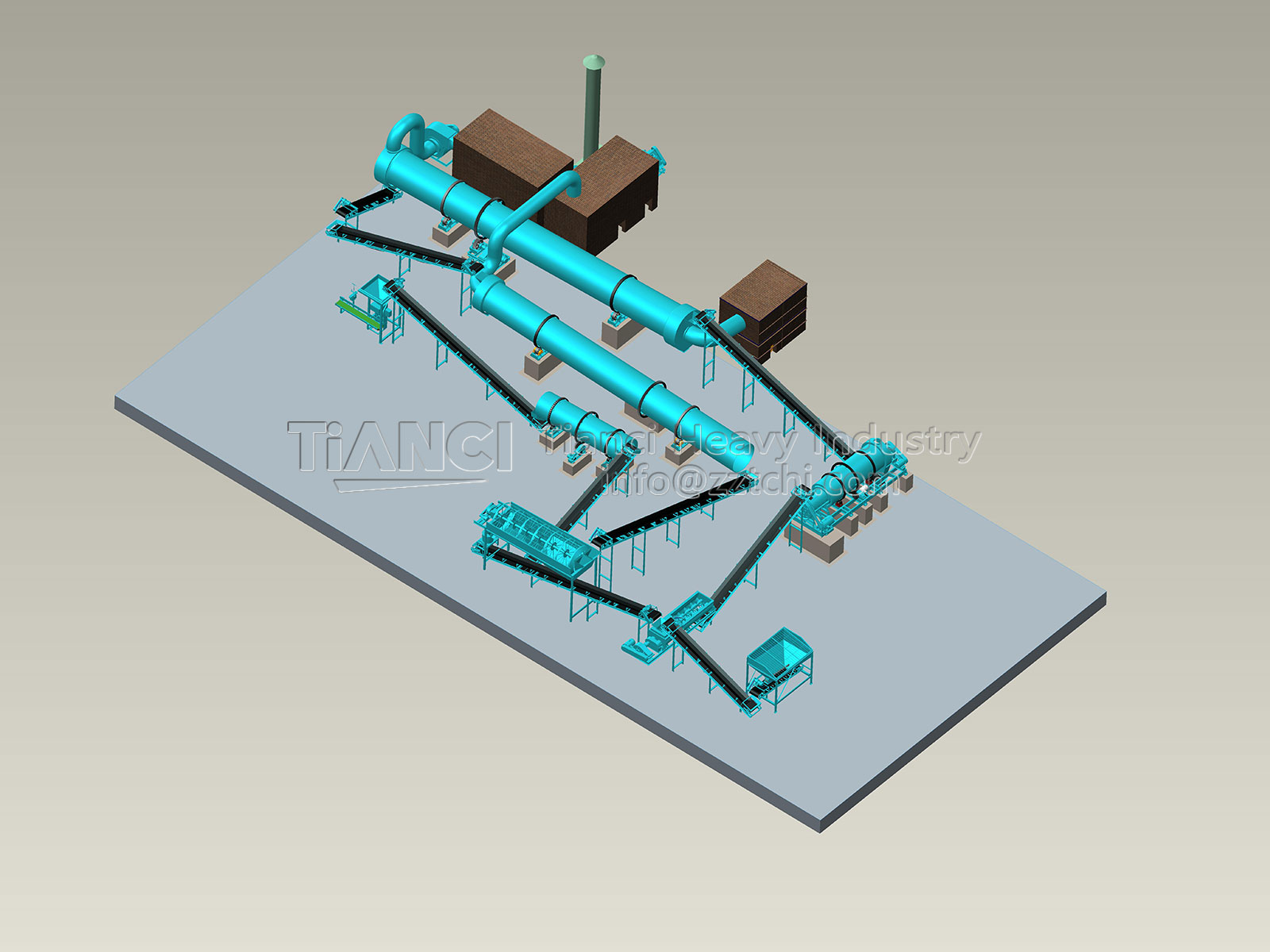

A complete set of organic fertilizer granulation production line process: raw material selection —> drying and sterilization —> fermentation —> crushing —> stirring —> granulation —> drying —> cooling —> coating —> screening —> metering and sealing —> Product storage.

The complete set of

fertilizer manufacturing equipment is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and finished product packaging system; (livestock and poultry manure and other harmless treatment) fermentation system includes: feed conveying It is composed of machine, biological deodorizer, mixer, proprietary turning and polishing machine, oxygen supply system and automatic control system.