2025-06-20

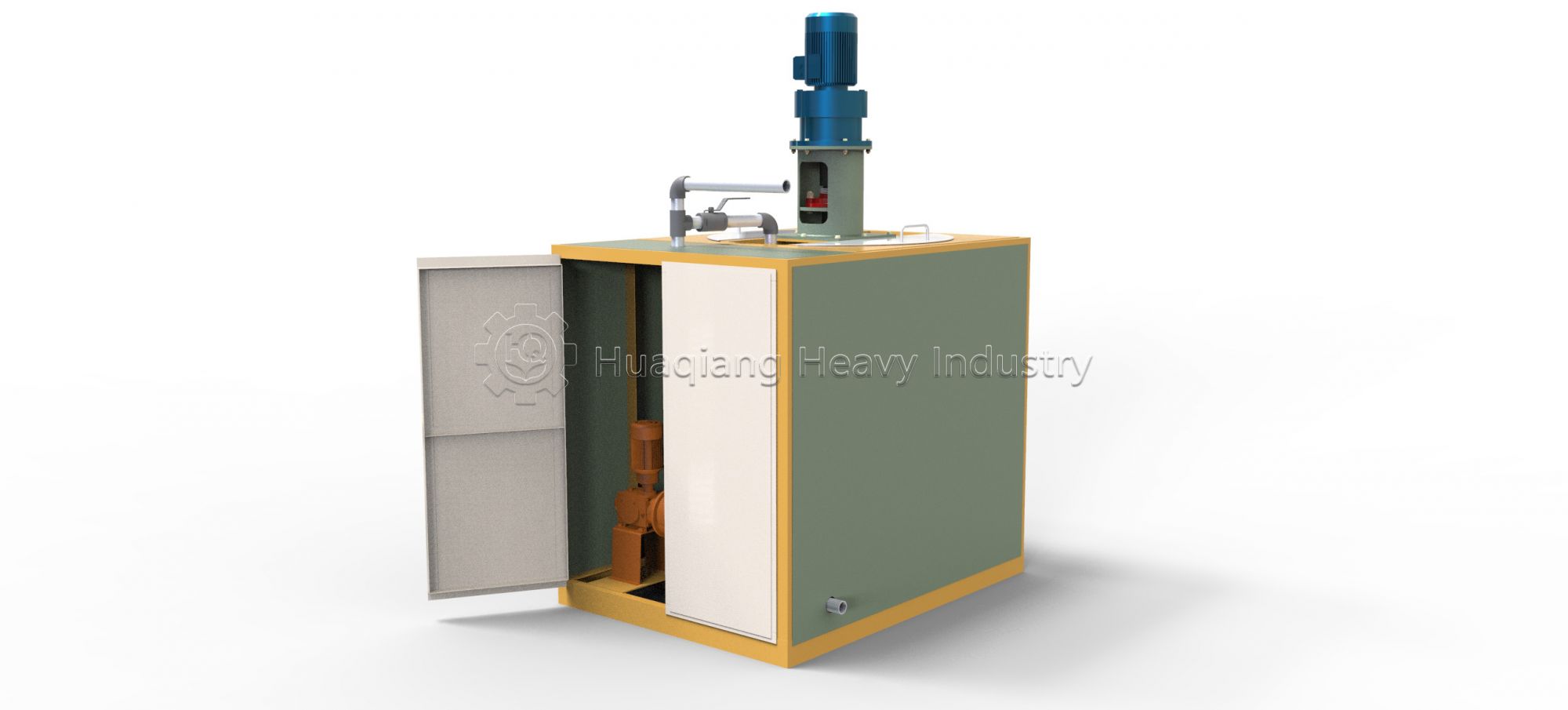

An electric heating melting mixing tank is a critical equipment in fertilizer production that converts electrical energy into thermal energy to melt solid raw materials and achieve homogeneous mixing. Typically constructed from stainless steel, it features heating elements, temperature control systems, and mixing mechanisms that enable precise control over melting temperature and duration[1].

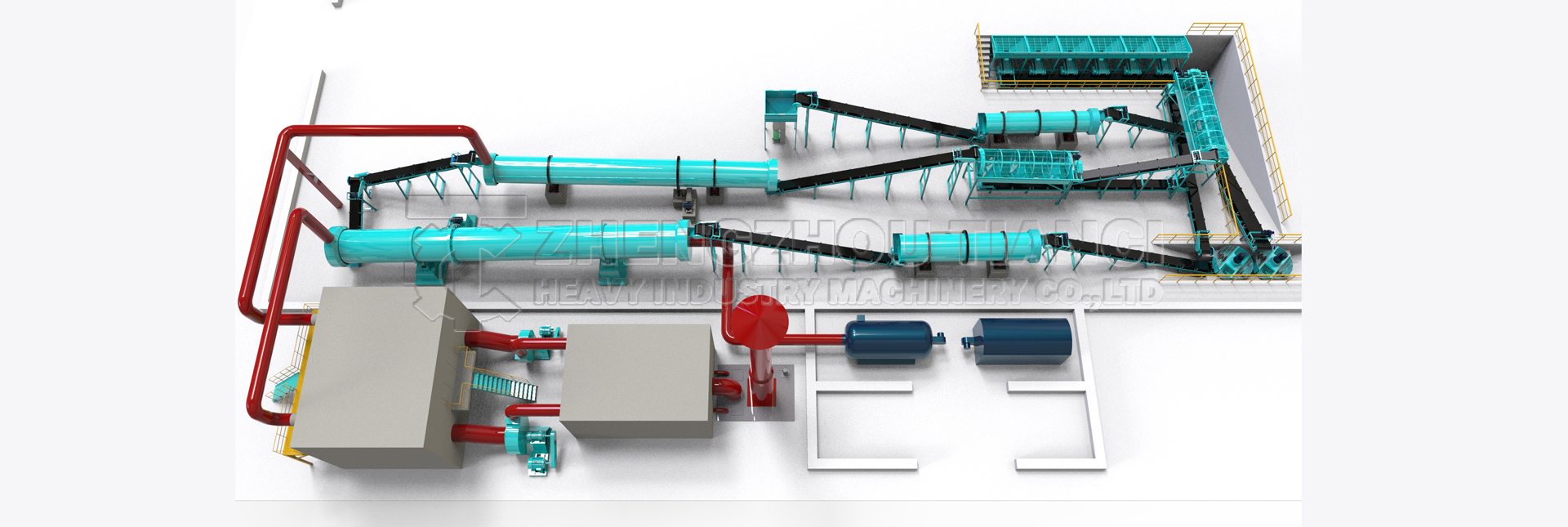

In compound or specialty fertilizer production lines, the electric heating melting mixing tank is usually positioned between the raw material pretreatment section and the granulation section. Its primary function is to melt various solid materials (such as urea, phosphates, etc.) into liquid form and ensure thorough mixing of components, providing ideal material conditions for subsequent granulation or coating processes[2].

· Precise Temperature Control: Achieves ±1℃ accuracy, preventing material decomposition

· Environmentally Friendly: No combustion emissions compared to gas heating

· Easy Operation: High automation with programmable control

· Uniform Mixing: Specially designed agitators ensure homogeneous blending

· Higher Energy Consumption: Electricity costs typically exceed traditional fuels

· Substantial Initial Investment: Higher equipment costs than conventional mixers

· Maintenance Intensive: Heating elements and control systems require regular upkeep

· Material Limitations: Not suitable for all heat-sensitive materials

Electric heating melting mixing tanks are particularly suitable for producing high-value specialty fertilizers like controlled-release or water-soluble fertilizers. Selection should consider production scale, material characteristics, and local electricity costs. For small-to-medium specialty fertilizer lines, their precision and environmental benefits often justify the higher operational costs[3].

References:

[1] Fertilizer Production Technology and Equipment Manual, 2020 Edition

[2] Modern Fertilizer Engineering Technology, by Zhang Nongye, 2018

[3] International Fertilizer Industry Association (IFIA) Technical Report, 2021