Raw Material Pretreatment: Transforming Waste into Resources

Distiller's grains (protein content 15-25%) and vinegar residue require the following pretreatment steps:

- Moisture adjustment: Reduce from 65-75% to 50-60% by adding 10-20% dry amendments (sawdust, rice husk)[1]

- pH balancing: Typically acidic (pH4.0-5.5), require 5-8% wood ash or lime to adjust to pH6.5-7.5[2]

- C/N ratio optimization: Add 15-20% livestock manure (e.g., chicken manure) to adjust C/N ratio from 30-40 to ideal 25-30 range

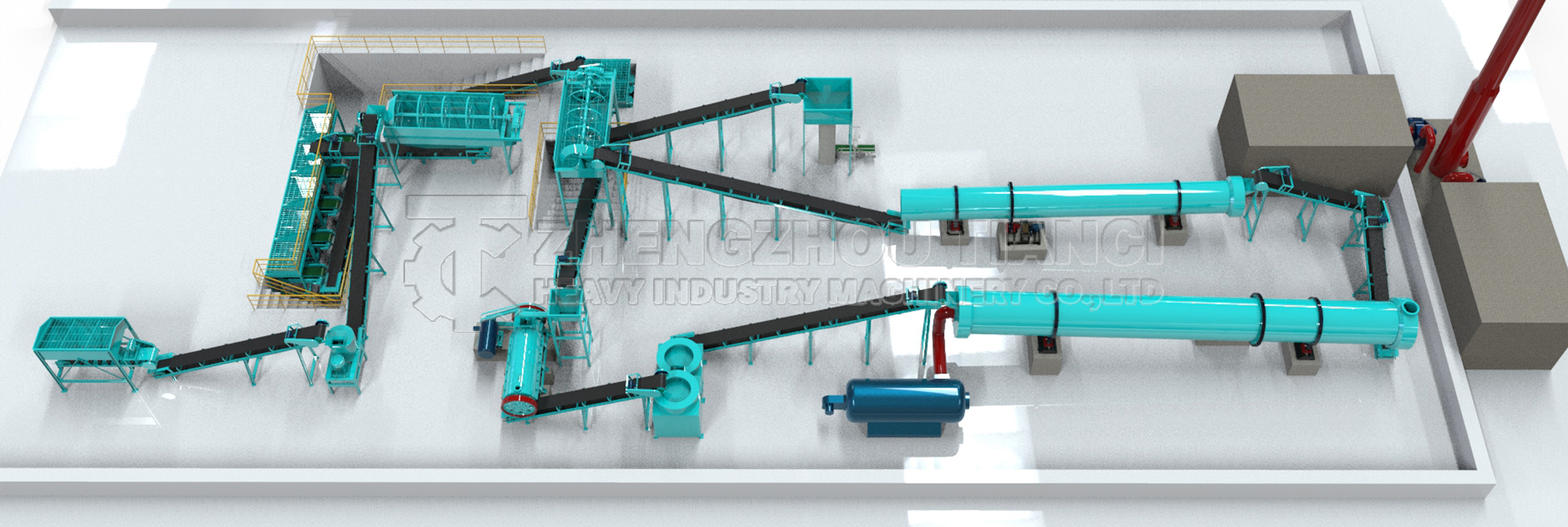

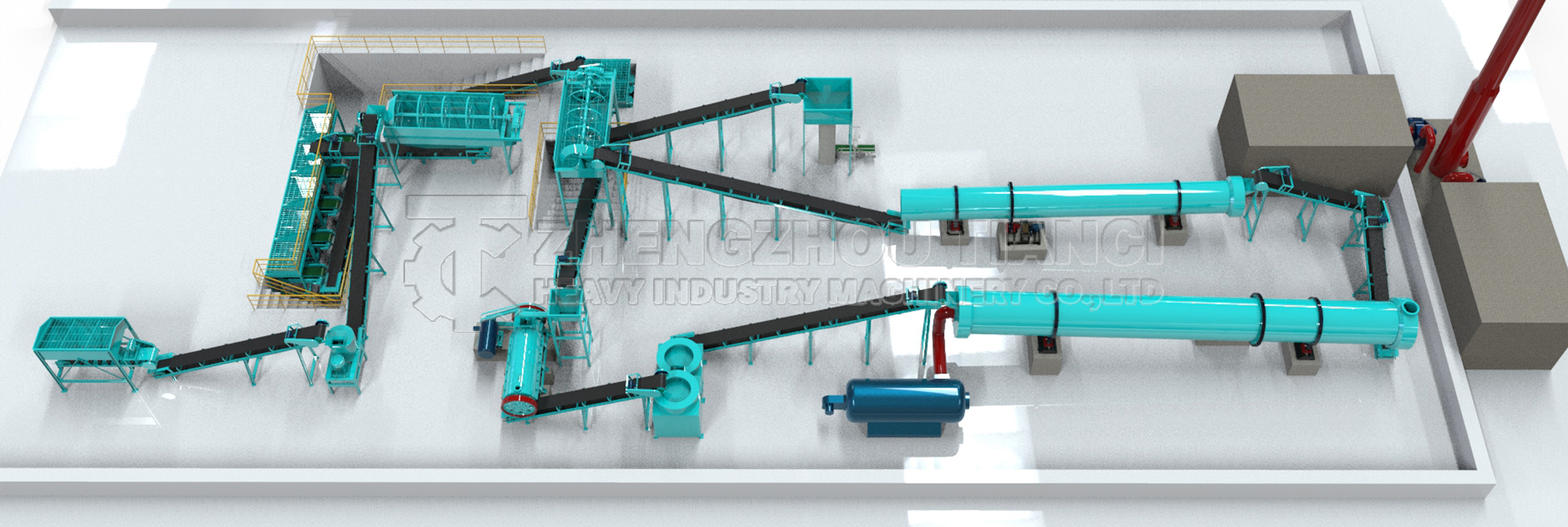

Core Components of Production Line

Pretreatment

Crusher

Mixer

Dewatering

Fermentation

Trough turner

Aeration system

(15-20 days)

Refining

Grinder

Screener

Dosing

Granulation

Disc granulator

Rotary drum

Post-processing

Dryer

Cooler

Packaging

Vital Role of Animal Manure

In this production process, animal manure plays irreplaceable roles:

- Nitrogen supplement: Chicken manure (N 1.5-3.5%) compensates nitrogen deficiency

- Microbial carrier: Indigenous microorganisms accelerate decomposition

- Physical improvement: Enhances pile porosity, prevents anaerobic fermentation

- Nutrition balance: Provides phosphorus, potassium lacking in distiller's grains[3]

Success Case Study

One bio-fertilizer plant uses formula: 20% distiller's grains + 30% vinegar residue + 50% chicken manure:

- Fermentation cycle shortened to 18 days (vs 25 days traditionally)

- Final product contains ≥5% NPK nutrients

- Organic matter content exceeds 45%

- Heavy metals far below national standard limits

References:

[1] "Utilization Technologies of Organic Solid Waste", China Env. Press, 2020

[2] Smith et al. "Brewery Waste Composting Optimization", Bioresource Tech, 2021

[3] FAO "Organic Fertilizer Production Guidelines", 2019 edition