2025-06-09

· "Oxygen Deficiency": When pile porosity <30%, aerobic microbial activity decreases by over 50%

· "Malnutrition": Imbalanced C/N ratio (ideal is 25-30:1) causes microbial "picky eating"

· "Abnormal Temperature": Failure to reach thermophilic phase (55-65°C) results in <90% pathogen kill rate

1. Add fermentation inoculants: Choose composite inoculants containing thermophilic cellulose-decomposing bacteria, which can shorten fermentation cycle by over 30%

2. Use "sandwich" composting method: Alternate layers of raw materials and inoculants to improve fermentation uniformity

3. Install temperature monitoring system: Real-time pile temperature monitoring to scientifically guide turning schedule

· When moisture >35%, material surface tension increases, creating "cement effect"

· Incomplete organic matter decomposition produces sticky polysaccharides

· Moisture absorption during storage causes secondary caking

|

Parameter |

Traditional Fermentation |

Smart System |

|

Fermentation Cycle |

25-30 days |

15-18 days |

|

Maturity Level |

70-80% |

≥95% |

|

Energy Consumption |

40kW·h/ton |

28kW·h/ton |

Engineer's Tip: When selecting fermentation equipment, choose trough systems with turning depth ≥1.8m to handle viscous livestock manure materials.

1. Add anti-caking agents: Such as diatomaceous earth, bentonite, etc., with dosage controlled at 3-5%

2. Optimize drying process: Use "low temperature with high air volume" drying method to avoid surface hardening

3. Improve packaging: Use double-layer packaging with moisture-proof inner bag + woven bag

To reduce costs while maintaining quality, focus on the following aspects:

1. Localize raw materials: Establish long-term partnerships with nearby farms and agricultural processing plants to reduce transportation costs

2. Process optimization: Replace windrow composting with trough fermentation to save labor and space

3. Energy recycling: Use fermentation heat to preheat raw materials or dry finished products

4. By-product development: Process screened coarse fibers into seedling substrates for additional income

Organic fertilizer production may seem simple but actually contains rich scientific principles and technical know-how. Only by solving these two "stinky" problems of fermentation and caking can we truly achieve high-quality, low-cost organic fertilizer production and contribute to green agriculture.

Note: All technical recommendations are based on current industry practices. Actual results may vary depending on specific conditions.

.jpg)

The windrow compost turning machine is used for stacking type fermenting technology on the ground. it is a special machine forturning, breaking,supplying oxygen and piling up materials.

1. The machine can be set the running speed of the wheel and turing axis according to the nature of the material, and get the

right yield and quality.

2. The power is vertical water-cooled diesel engine with sufficient power, high efficiency and low fuel consumption.

3. The turning direction is in the direction of pull bar, and the turning is flexible, small area, and the convenient.operation.

4.Using electric button switch, joystick operation, flexible and simple.

5. According to the customer's request, the distance between the axis and the ground can be adjusted by hydraulic pressure toprevent the turning of the turning shaft.

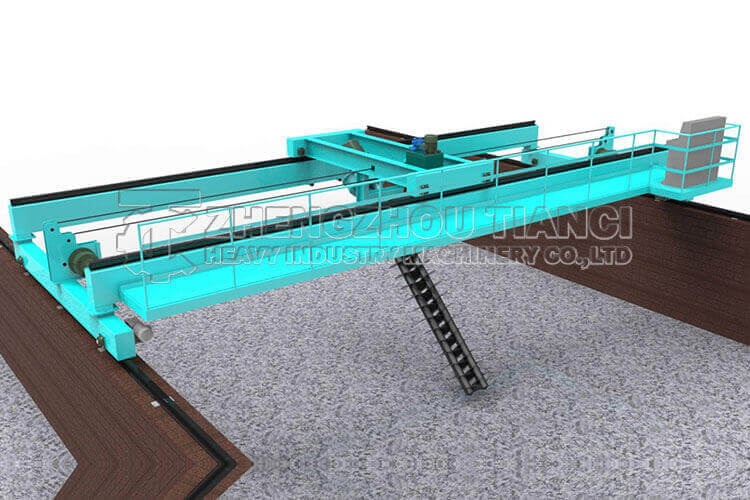

The double screws compost turning machine is suitable for fermentation of livestock waste, sludge waste, sugar refinery filtelmud, straw sawdust and other organic wastes. lt overcomes the limitation of the width and depth of the traditional groove tumingmachine. The turning depth can reach 1.6 meters and the turning width can reach 12 meters, which greatly improves the spaceutlization ratio.After the improved double axis reverse rotation movement, it has the function of tuming, mixing and oxygenation.improving the fermentation rate, decomposing the composting quickly, preventing the formation of the odor, saving the energyconsumption of oxygen filling, and shortening the fermentation time.