2025-06-07

Bio-organic fertilizer production lines utilize microbial fermentation technology to transform agricultural waste into high-quality fertilizer rich in organic matter and beneficial microorganisms, achieving a remarkable transformation from "pollution source" to "nutrient source." This process perfectly aligns with the three core concepts of green agriculture:

· Material Cycling: Completes the closed-loop flow of "livestock farming - crop cultivation - soil"

· Environmentally Friendly: Reduces chemical fertilizer usage by 30-50%, decreasing non-point source pollution

· Quality Enhancement: Increases average vitamin content in agricultural products by 15-20%[1]

Modern bio-organic fertilizer production lines have evolved into "organic fertilizer factories" incorporating intelligent control systems, online monitoring equipment, and precise proportioning systems. Their fermentation efficiency is 5-8 times higher than traditional composting, with a harmful substance degradation rate exceeding 99%[2].

The unique advantages of bio-organic fertilizers are particularly prominent in the following scenarios:

· Organic Farm Certification: Meets stringent production standard requirements

· Soil Remediation Projects: Achieves 60-80% efficiency in heavy metal passivation

· Specialty Crop Cultivation: Such as tea, medicinal herbs, and other quality-sensitive crops

Bio-organic fertilizer production lines are evolving in three directions:

· Intelligentization: Application of IoT technology for remote monitoring and optimization

· Modularization: Development of mobile small-scale equipment for family farms

· Functionalization: Research and development of special-function fertilizers with disease resistance, drought resistance, etc.

The newly developed "Bio-organic Fertilizer 4.0 Production Line" in the Netherlands has achieved fully automated operation. Through AI algorithms optimizing fermentation parameters, it reduces energy consumption by 30% while increasing product microbial activity by 50%[3], representing the future direction of the industry.

Core value: Transforming pollutants into commercial organic fertilizer meeting NY 884 standards, achieving both environmental compliance and economic benefits.

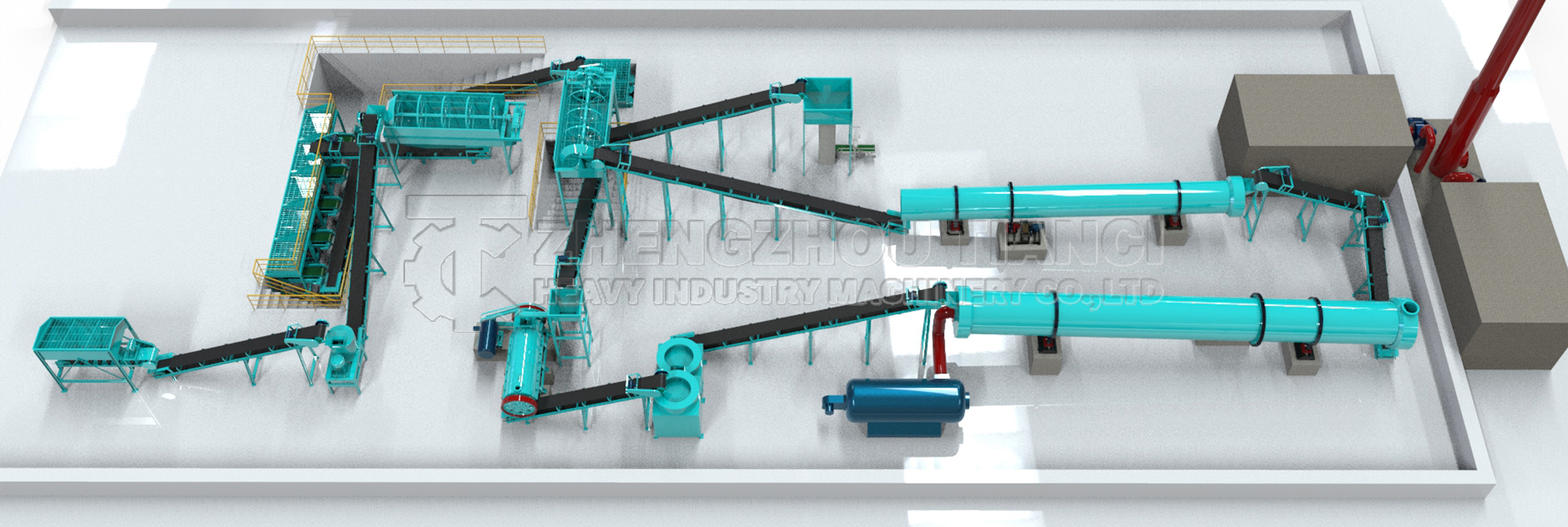

· Pre-processing equipment: Crushers and screens for preparing organic materials.

· Fermentation equipment: Turntables and tanks for controlled microbial fermentation.

· Post-processing equipment: Granulators, dryers, coolers, and screens for final product formation.

· Mixing equipment: For blending fermented material with additives like microbial agents.

· Packaging equipment: Automatic packers.

· Control system: PLC systems for monitoring temperature, humidity, and oxygen levels.

1. Agricultural waste treatment: Large-scale processing of livestock manure, straw, and mushroom residues.

2. Environmental upgrades: Helping farms, food waste centers, and processing plants meet environmental standards.

3. Fertilizer industry transformation: Supporting organic-inorganic compound fertilizer production or new organic fertilizer plants.

[1] China Agricultural University. Research Report on the Impact of Organic Fertilizers on Agricultural Product Quality. 2022

[2] IFOAM. Global Organic Fertilizer Technology White Paper. 2023

[3] Wageningen University. Smart Organic Fertilizer Production Systems. 2023