Abstract:

1. Production scale: Production of solid organic fertilizer ××T/d, annual output ×××××ton.

2. Product Standards: Implementing the Agricultural Industry Standard of the People's Republic of China "Organic and inorganic compound fertilizers"(NY/T XXXX-2001)

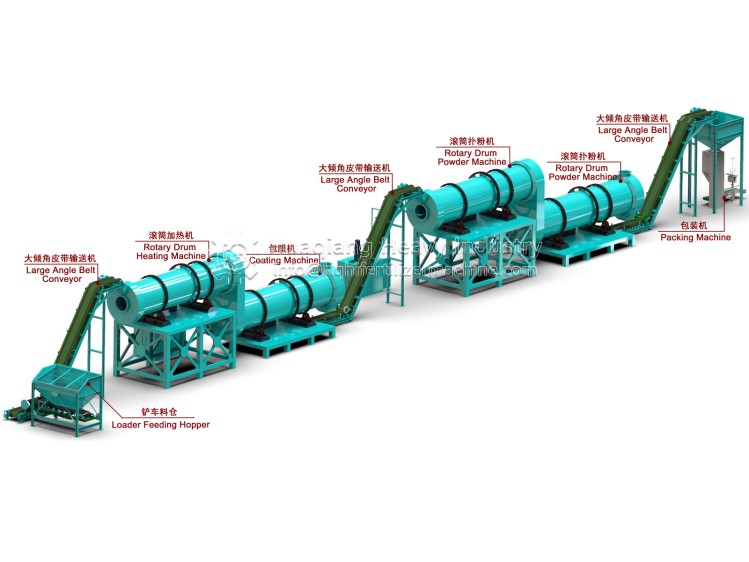

3. Production Process: Solid organic compound fertilizer: pic 1

Liquid organic fertilizer: pic 2

4. Investment: ×××××yuan(According to your annual output and specific demands.)

5. Land occupation: ××are(According to the specific conditions)

6. Operating costs: 0.918yuan/ton ( depreciation: 1.150yuan/m3)

7. Labor capacity: × (According to the specific conditions)

8. Construction period: 6 months

1.

Product Plan:

1. The quality of this product meets the national standards for organic fertilizers, green food special fertilizers and organic compound fertilizers. Implementation of the People's Republic of China agricultural industry standard "organic inorganic fertilizers" (NY/T XXXX-2001).

2.The product model is divided into food, vegetables (fruits and vegetables, leaves), fruit trees, flowers, lawn five series. Each series is formulated according to the growth characteristics of the crop.

The organic fertilizer mainly has the following characteristics:

1. The nutrients are enough, and has high content. Contains various nutrients necessary for crop growth.

2. The long-lasting fertilizer effect means that there is prodigious and post-effect. It can fully meet the demand of various nutrients for the whole growth period of the crop, and it will not be deferred during the later growth period.

3. It’s easy to use, as a one-time application of base fertilizer, the application method is simple, and it can save labor, save time, and effort.

4. It has the low cost, and is the lowest price of similar products.

5. High efficiency, input-output ratio of up to 1:10 to 30 or more.

6. Widely used, widely applicable to all kinds of soil and various crops, including a variety of greenhouse vegetables, fruit trees, economic crops, food crops and herbs, flowers, lawns, seedlings, etc. (different recipes).

2. Construction Conditions

The reliability of raw material supply, the main raw material of this product is livestock and poultry excrement, and accessories include: wastes such as peat, sawdust, straw, bean cake, horn bone powder, etc.

3.Production ProcessSolid organic compound fertilizer production process: pic 1Liquid organic fertilizer production process: pic 2The mainly raw material of organic fertilizer production: farm pig manure, cow dung, chicken manure, etc.; ingredients include: straw, charcoal, grass carbon, rice husk and so on.The process of organic fertilizer production: Organic materials are inoculated with fermentation (prep-fermentation), main fermentation, smashing, compounding and mixing, drying, granulation, cooling, screening, and measuring and packaging.Organic Fertilizer Granulation Production Process:

4.Instruction of Production Process

The basic process is briefly described as follows:

1. Fermentation process section

(1)

Pre-fermentation

(2)

Main fermentation

2. Compound process section

(1)

Crush

(2) Raw materials mix

(3) Water content control

3. Granulation process section

(1)

Crush

(2)

Compounding and mixing

(3)

Granulation

(4)

Drying

(5)

Cooling

The Features of this process:

1. Using anaerobic fermentation and high-temperature two-stage fermentation to recover and utilize bio energy. The project intends to use biogas to generate electricity, using mature gas generators or dedicated biogas generators.

2. The organic special granulator can produce solid spherical particles at 20%~40% moisture content, which greatly saves energy and equipment and improves efficiency.

3. In the drying process, special features include polishing and mixing to make the material more sleek.

4 . It can be pure organic fertilizer granulation, or organic, inorganic fertilizer granulation, no special requirements for granulation materials.

Production Equipment List

1. Fermentation equipment: Water seal can, flame arrester, biogas boiler and so on.

2. Granulation equipment:

Belt conveyor,

crusher,

granulator,

dryer,

mixer,

cooler,

screen,

packing machine and so on.

If you want to know more information about this, please contact us.