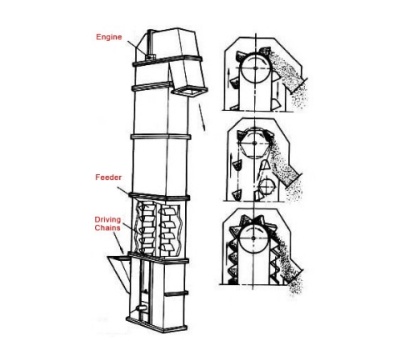

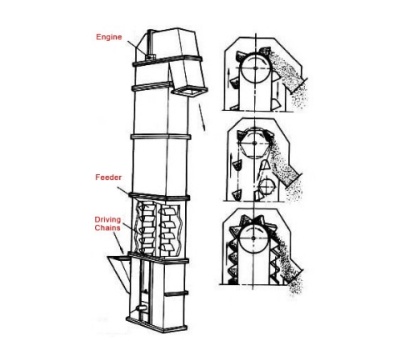

The fertilizer production machine Bucket Fertilizer Elevator Brief Introduction

Bucket elevator is to convey powder,granules and small lump materials whose piling density is less 1.5T/M3 and temperature is below 250C. The conveying hopper volume is large enough to satisfy the general fertilizer production machines. It adopts chains structure and can conveys stably.

The trailer part of bucket elevator is round chain which is made from superior quality alloy steel. The middle elevator rack can be made into single and double channels. Chain wheel is changable chains and has long working life. The bottom part is equipped with gravity automatic takeup device to offer constant tension. At the same time, when feeder gets stuck accidiently, the device can protect elevating shaft and other components.

This series of bucket elevator has the characteristics of small floor area, high lifting height, large conveying capacity, low power consumption and good tightness. The utility model is suitable for vertical conveying equipment of granular and powdery materials, such as chemical fertilizer, grain, food, fodder, mining industry, etc..

The driving power is small, the use of inflow feeding, induction discharge, large capacity hopper intensive layout. In the lifting of materials, almost no return and excavation phenomenon, therefore, less power.

The utility model has the advantages of wide range of hoisting, low requirement of the type and characteristic of the material, not only the general powder and small granular material can be promoted, but also the material with good grinding property can be improved, and the sealing property is good, and the environmental pollution is less.

The operation reliability is good, the advanced design principle and processing method ensure the reliability of the whole machine, and the trouble free time is more than 20 thousand hours. The lifting height is high. The hoist runs smoothly, so it can achieve a higher lifting height.

The service life is long, the feeding of the lifter adopts the inflow type, and the material is not needed to be dug by the bucket, and the extrusion and the collision are rarely occurred among the materials. This machine in the design to ensure the materials in the feeding and unloading is less scattered, reduces the mechanical wear.