Organic fertilizer crusher is an important link in the production line of chicken manure organic fertilizer. It also has a special machine for processing. The emergence of the organic fertilizer crusher greatly reduces the human crushing, and the efficiency of the organic fertilizer processing is also greatly improved.

The technology of organic fertilizer crusher integrates the crushing function of materials after fermentation. After the material is dehydrated, the crusher can effectively break the fertilizer lumps formed in the fermentation process easily, which not only saves the work of the crusher, reduces the cost, but also improves the grinding efficiency, and fundamentally solves the disadvantages of the crusher. The organic fertilizer crusher is suitable for the comminution of wet materials after composting and fermentation. It is widely used in the comminution process of high humidity materials, such as organic minerals, humic acid, lignite, pig manure organic fertilizer, chicken manure organic fertilizer, sheep manure organic fertilizer, cow manure organic fertilizer, biogas residue organic fertilizer, urban domestic waste, etc. The inner part of the equipment is equipped with a forced discharging screw device to make the machine non stick and non block, and the discharging fineness can reach 80 mesh. The machine solves the problem of crushing high water content materials.

Organic fertilizer production equipment not only processes the fermentation materials much faster than the traditional fermentation method, but also effectively prevents the production of hydrogen sulfide, ammonia and other harmful gases in the fermentation process, which not only meets the environmental requirements, but also can produce good organic fertilizer. Chicken manure composting meets the requirements of the mechanism and technology of microbial fermentation. The organic manure crusher can effectively mix the viscous livestock manure with microbial agents and straw powder. It takes about three hours to deodorize chicken manure in the loose material state, and the fermentation temperature is controlled at about 60℃ for four days. The fertilizer can be formed in 7 days, and the number of beneficial microorganisms in the soil is not less than 30 billion / g.

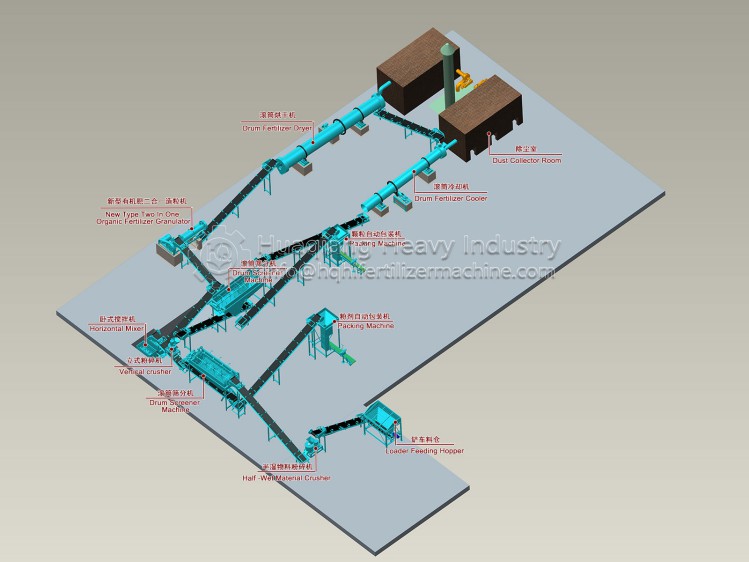

The comminuted compost is favorable for granulation. The raw material is crushed into powder and processed into granule by fertilizer granulator, which is more convenient for use.