In the vast fields, crops thrive and provide us with abundant food and resources. And behind that, fertilizer plays a crucial role, it's like the vitality of the crop. At the same time, fertilizer production machines are the key to ensuring efficient and high-quality fertilizer production.

The growth of crops is inseparable from various nutrients, and fertilizer is an important source of these nutrients. Different types of fertilizers can meet the needs of crops at different growth stages. Nitrogen fertilizer can promote the growth of plant branches and leaves, making it more luxuriant; Phosphorus fertilizer is helpful for root development and flower bud differentiation, which lays a solid foundation for crop flowering and fruit. Potash fertilizer can enhance the plant's stress resistance, improving its resistance to pests and diseases and harsh environments. In addition, there are a variety of compound fertilizers and organic fertilizers, which combine a variety of nutrients to provide comprehensive nutritional support for crops.

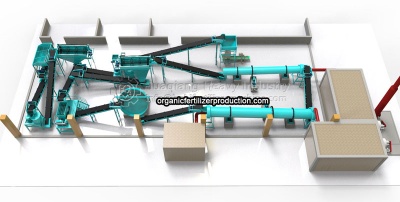

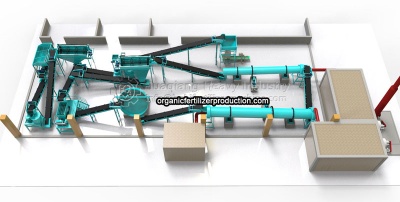

However, to convert various raw materials into high-quality fertilizers, advanced fertilizer production machines are indispensable. There are many kinds of fertilizer production machines, each of which plays a unique role in the fertilizer production process.

The first is the crusher, which can crush large pieces of raw materials such as ore and organic waste into fine particles, creating conditions for subsequent processing.

For some organic fertilizers that need to be fermented, the fermenter has become a key equipment. The fermentation machine can control conditions such as temperature, humidity and ventilation to provide a suitable environment for the growth and reproduction of microorganisms. During the fermentation process, organic matter is broken down and transformed, releasing rich nutrients, while also killing harmful germs and eggs.

The granulator turns the powdered fertilizer mixture into pellets. Granular fertilizer has better fluidity and stability, and is easy to store, transport and apply.

In addition, there are dryers, screening machines and other equipment, respectively, for removing moisture in the fertilizer and screening particles that meet the specifications. These devices work together to ensure that the quality of the fertilizer produced is stable and reliable.

In short, fertilizer is an indispensable source of vitality for crop growth, and fertilizer production machines are important tools to achieve efficient and high-quality fertilizer production. With the continuous progress of science and technology, fertilizer production machines will continue to innovate and improve, and make greater contributions to the sustainable development of agriculture.