The compound fertilizer equipment drum granulator can properly install and debug, which can not only greatly improve the production efficiency, but also reduce the production cost and extend the service life.

1. Hoisting the barrel of the drum granulator for compound

fertilizer manufacturing equipment

Before hoisting, check the actual size of each foundation, make a record and design the corresponding treatment measures. Place the bolts and other connecting parts, anchor bolts, and adjustment pads in a convenient place to prepare them for adjustment. Hoisting needs to find the corresponding balance point, first carry out a trial hoisting, and then slowly move to the installation position after ensuring stability. First, adjust the installation angle of the cylinder. The method is determined by a level. A simple method can use a transparent water pipe to find the height difference between the two points of the required slope, which can also meet the requirements. The contact surface of the supporting ring is 0.1 -1mm feeler gauge inspection, and adjust the parallelism between the center line of the left and right supporting wheels and the center line of the cylinder to ensure that the contact surface between the supporting wheels and the supporting ring is uniform; the height difference between the center lines of the left and right supporting wheels must also be reached Equipment installation process requirements.

2. Installation of belt hoist for metering equipment in the

NPK fertilizer manufacturing process

If equipped with a metering belt, you need to pay attention to the installation of the metering belt conveyor to maintain a level, the installation of the speed sensor and pressure sensor must meet the requirements of the compound fertilizer production line manufacturer, and the signal line and the power line are required to maintain a reasonable distance to avoid signal interference. Lead to inaccurate or impossible measurement. The installation of the belt conveyor and hoist is as convenient as possible for maintenance and cleaning, and keep the material on the equipment smooth, and enough space for cleaning and maintenance.

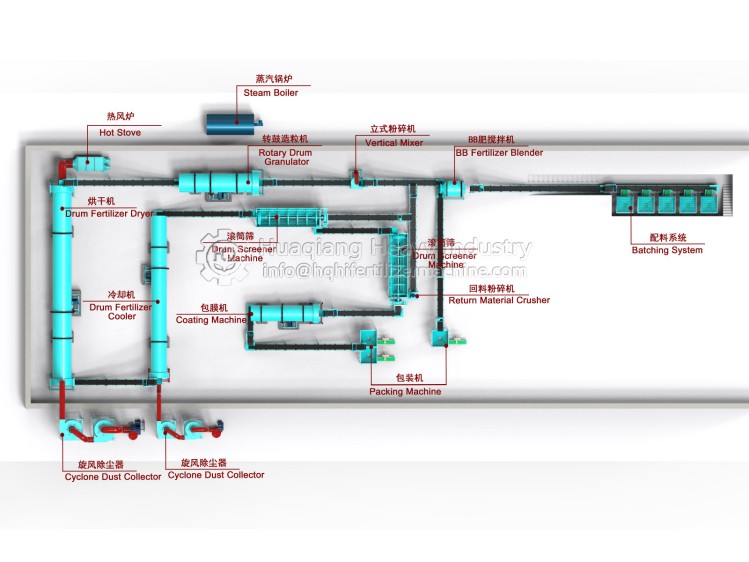

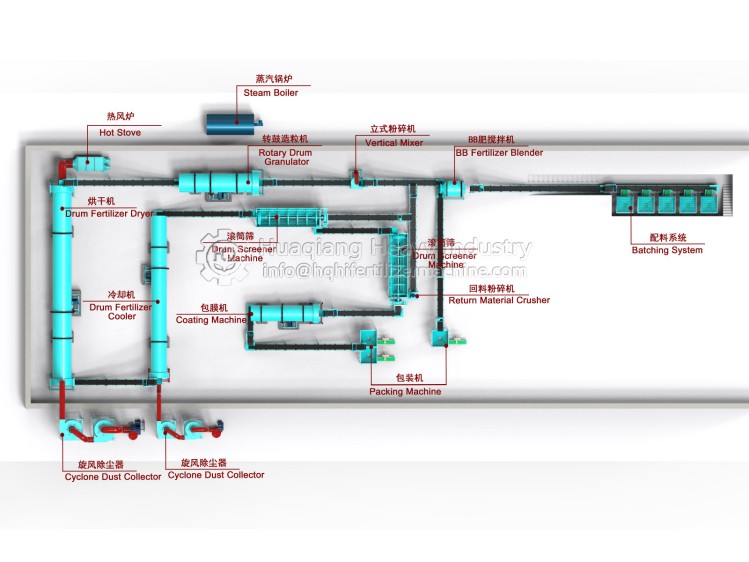

3. Installation of cage grinder, screening machine, fan duct, hot blast stove, dust removal equipment

This type of equipment is the key to affecting the workshop environment. The source of dust is pulverizers and screening machines, and bad sealing results in serious air leakage. Not only does it affect the dust removal efficiency of the fan, but more importantly, it increases the difficulty of dust removal in the workshop. The hot air stove cage type is generally better to be relatively isolated from the workshop, so as to avoid the heat dissipation of the hot air stove and cause the temperature in the workshop to be too high. It is recommended to use the gravity method for dust removal to avoid the cyclone dust removal powder from adhering to the inner wall of the dust collector and continuous production.

4. Wire and cable installation and electrical debugging

The installation of electrical equipment is also a crucial part of the complete compound fertilizer equipment. Usually the power part and the control part are installed separately, mainly involving the following two parts:

(1) Good grounding system.

Although there are no flammable and explosive materials, if the equipment leakage and other accidents are also possible, do not install in accordance with the corresponding electrical installation specifications to reduce the investment;

(2) Cable installation

For the signal line (mainly the measured pressure signal and speed signal here) and the signal of the temperature measuring device, special signal cables should be used, and there should be no interference with the power line.

Other matters needing attention in the installation of

drum granulation machine of compound fertilizer equipment

1. Installation of chute, bucket and pipeline

In the installation process, it is inevitable that there are various chutes, buckets, pipe modifications that need to be made on site, and the materials should be smooth after production, the surface should be smooth, and the welding slag and other spatters should be removed, and anti-rust paint should be done;

2. The use of installation equipment

Welding machines, cutting machines and other tools should strictly abide by the operating procedures, and need to be certified to work to avoid unnecessary losses. Typically, the electric welding machine is poorly grounded, causing the coil of the motor to be burned, and the bearing of the supporting roller is damaged by pitting.