Disc granulator(also called pan granulator) is an important part of organic or compound fertilizer production production line in our company. Disc pelletizer machine is widely used for producing round granules of organic fertilizer and compound fertilizer. By this way, fertilizer pellets are convenient for transportation and storage. In terms of the features of its wide application and highest pellletion ratio up to 93%, a fertilizer granulator is an ideal pellet machine for your fertilizer production among a bit of machines. There are various models of fertilizer pelletizers which differ from inner diameter, side height, and rotating speeding in our company. Besides, as a disc granulator supplier, eco-friendly pan granulation machines in different production capacity can meet our client requirements. In a word, it has the big perception and potentiality of fertilizer granules producing companies among the global.

The design of pan granulator working principle is very simple. Therefore, it is popular in industry. And construction of disc pelletizers is consist of several parts, the whole design is elaborate and durable. The parts are alternatively the disc, the gears, the motor and decelerator and the transmission belt. All of them plays important roles in the process flow diagram for disc pelletization. Now we will introduce them separately.

In order to get suitable pellets, the angle design of pan granulation machine is adjustable from 1'to 90° in the line with flat ground in our company. The angle between pan plate and the flat ground decides the size of fertilizer pellets. When the angle reaches up to 65°, the size of fertilizer is smaller. The angle varies under 40°, the size become larger. Therefore, the proper angle (40°-60°) is key to get qualified fertilizer granulars. During this period, qualified fertilizer pellets is available. Please following our instruction of guideline or our sales manage advice to operate disc granulation machine.

There are several advantages of disk granulator:1. High quality granulation rates Adopt whole arc

disc angle, the granulation rate can reach above 93%. Then, having three discharge ports makes it convenient for intermittent production, greatly reducing the labor intensity and improving labor efficiency.

2. Advanced materials for manufacturing process of disc pelletizer The material adopts stainless steel plate which makes the fertilizer equipment use for a long time.

3. Disc granulator operation system is fully automatic. Automatic material clearing plate above the sticking materials, improving service life of equipment and saving labor. It only needs a control panel box for granulation machine to work. Therefore, it can save more labors for some small scale disc pelletizer iron ore pellet plant.

4.Reasonable price as a pan granulator manufacturer We belong to direct selling, not third party. Therefore, you get more details of products and price list without any agency cost.

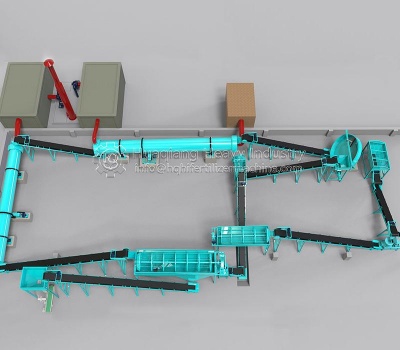

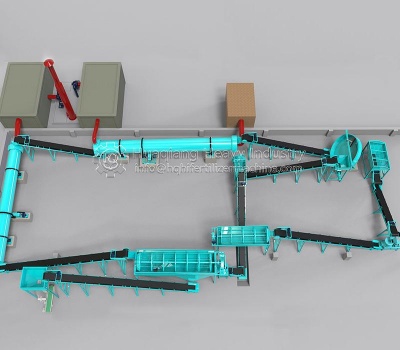

In addition to the disc granulator there are other kinds of pelletizer, we have a professional production line from ingredients to packaging, welcome to visit and consult.