2024-06-17

Compared to synthetic fertilizers, Green Fertilizers have the following advantages:

★Multi-nutrition.Green fertilizer promotes crops growth and has high fertilizer use efficiency. It improves yields and quality of agricultural products.

★0rganic fertilizers generally come with a lower percentage of salt than their synthetic counterparts. Therefore they reduce nitrate pollution and less water is required to dilute the fertilizer.

★Bio organic fertilizers act as soil conditioners, thus they improve soil structure and loosen hard soil. In the meantime, bio organic fertilizers increase water absorption by plants, and improve crops' drought tolerance ability.

★Raw materials of bio organic fertilizer mainly come from organic and biodegradable solid waste, such as pig manure, chicken manure, food waste,SMW etc. Therefore, they have great price advantage.

Bio Organic Fertilizer Production Plant Design

Some of the Basic Conditions in Bio Organic Fertilizer Project Investment

a.Raw materials: there should be rich organic materials around the factory. The raw materials may include: animal manure, farming waste,biodegradable MSW, filter mud etc. Therefore, it had better to establish bio organic fertilizer plant near farms, livestock breeding farms, agricultural products processing factories,sugar mills etc.

b.Factory and warehouse: it is designed in accordance with the annual output of the plant. Taking an bio organic fertilizer plant with more than 10,000 tons annualoutput for example, warehouse area should be about 400㎡, the whole plant area being 3,000㎡ (fermentation land area: 2000 m, industrial shed:1,000 ㎡).

c.Circulating funds.

Basic Raw Materials, Adjuvants and Formulation:

☆Basic Organic Raw Materials:50-80% organic municipal solid waste such as livestock manure, sludge, and household garbage.

☆Basic inorganic materials: accounting for 10-30%, urea, ammonium phosphate, calcium, coarse whiting, potassium chloride, potassium

☆ 5%-10% bio fungi powder

☆other materials: peat, fly ash etc.

☆ Auxiliary energy supply: water, electricity, coal

Technological Process of Biological Organic Fertilizer Production:

Selection of the raw material (animal manure, sludge, industrial waste, etc.) - drying and sterilization - mixing ingredients - granulation - cooling and screening-weighting and packaging-finished product storage.

The technological design of biological organic fertilizer production technology includes:

1. High-efficiency complex microbial inoculants and propagation technique;

2. Advanced allocation technology of raw materials and biological fermentation system;

3. The optimum specialty fertilizer formula technology (We can design best combination of product ingredients according to the local soil and their crops' character);

4. Reasonable secondary pollution (exhaust gas and odor) control technology;

5. Design manufacturing technology for complete sets of fertilizer making machine;

6. Granulating and Polishing Technology

It is the core of this technology, and it is the patented technology, rolling the ball at one time with the finished kneading material, no-returned materials, high-efficiency,and the particles are good strength.

*Beautiful appearances, reasonable structure, safe and reliable quality, easy operation.

*During the working process, it has the strong ability which can stand the over temperature, even if in the situation of fully loaded, it won't be jammed, and there is no need to set up the charging gear additionally.

*Small power and high production, it is widely used for granulation in different industrial production, such as organic fertilizer, feed, husbandry, sewage treatment etc.

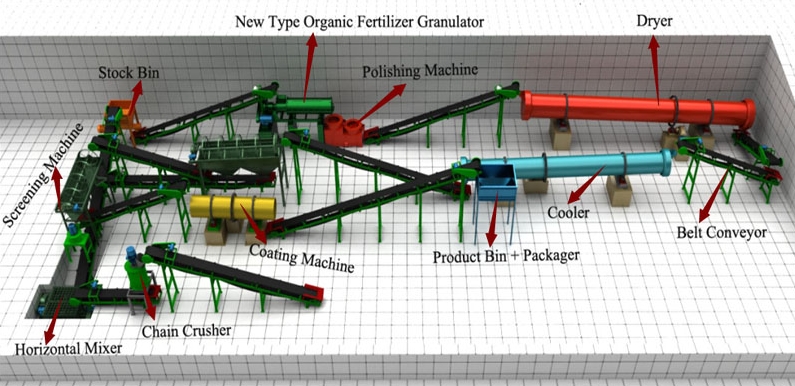

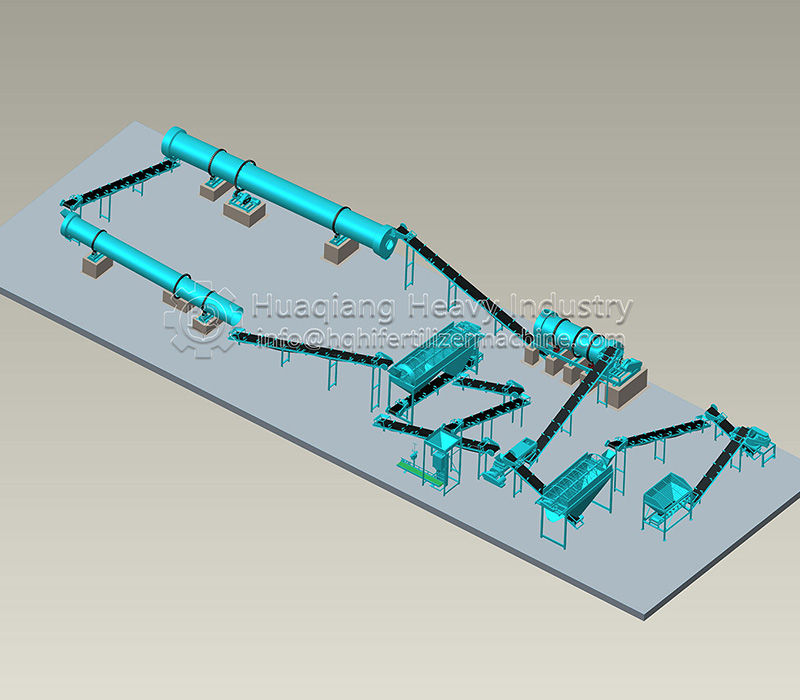

Fertilizer Machines Equipped in this Bio Organic Fertilizer Production Plant

The complete set of fertilizer making machine is composed of fermentation system, drying system, dust removal and deodor system, grinding system, batching system, hybrid system, granulation system (organic fertilizer granulating machine), screening system (rotary drum screen), and finished product packing system (organic fertilizer packager). The fermentation system, innocence treatment for the livestock and poultry manure, is consisted of the feed stock conveyor, biological deodorization machine, fertilizer mixing machine (pan mixer), the dedicated compost windrow turner (hydraulic compost turner), oxygen system and the automatic control system.