2025-07-02

The BB (Bulk Blending) fertilizer production line is a system for physically mixing different types of base fertilizer granules (such as urea, DAP, MOP, etc.) in specific proportions. The name "BB" comes from the abbreviation of "Bulk Blending". This production method has been used in Europe and America for over 60 years.

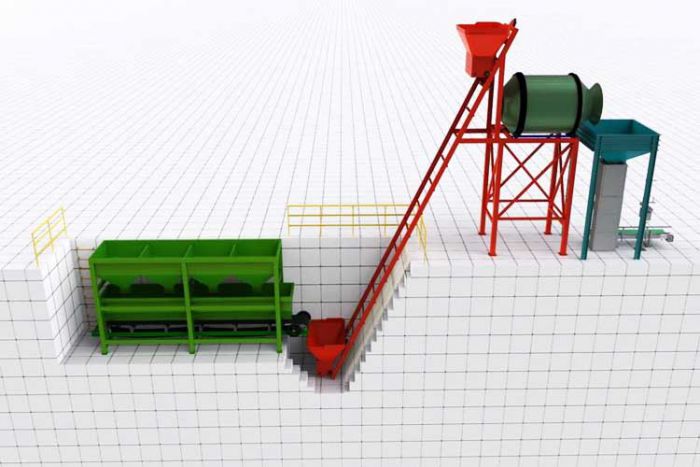

Core equipment of BB fertilizer line includes: raw material silos, automatic batching system, mixer, packaging machine and dust removal system. The entire production process typically takes only 15-30 minutes.

Compared with "npk fertilizer production line" which requires chemical reactions, BB fertilizer lines have significant advantages:

· Lower investment: Equipment costs only 1/5-1/3 of NPK lines

· Production flexibility: Quick formula adjustment for different crop needs

· Energy efficient: No granulation or drying processes, saving over 50% energy

· Less nutrient loss: Physical mixing avoids nutrient loss from chemical reactions

· Quick startup: Production begins in minutes versus hours needed for NPK line preheating

1. Raw material preparation: Ensure similar granule strength (2-4kg/granule) and matched particle size (2-4mm) to reduce segregation

2. Precision batching system: Use high-accuracy loss-in-weight feeders (±0.1%) with auto-compensation

3. Efficient mixing equipment: Choose double motion mixers with mixing uniformity CV≤5%, 3-5 minutes per batch

4. Automated packaging: Integrated weighing, sewing and coding systems reaching 10-15 bags/minute

5. Intelligent control system: PLC+HMI control for formula management and production data tracking