2025-10-16

Innovative Equipment and Processes for Sustainable Agriculture

Modern organic fertilizer production has evolved into a sophisticated technological process where biological principles merge with advanced machinery to transform organic waste into valuable agricultural inputs. This comprehensive system relies on specialized organic fertilizer manufacturing machines engineered to optimize the entire composting cycle while preserving the natural benefits of organic matter. A typical fertilizer production machine integrates crushing, mixing, granulation, drying, and packaging functions, creating a seamless operational flow from raw material to finished product.

Each organic fertilizer machine is designed to handle specific organic materials while maintaining nutrient integrity, particularly crucial for bio organic fertilizer production where microbial activity must be preserved. The selection of appropriate fertilizer machinery directly impacts product quality and production efficiency, making the choice of a reliable fertilizer machine manufacturer critical for operational success. These technological advancements in fertilizer production equipment enable manufacturers to create customized, high-value organic amendments that support sustainable agriculture while effectively managing organic waste streams.

The journey of organic fertilizer production begins with careful selection and preparation of raw materials. Agricultural residues, animal manure, food waste, and other organic substances are meticulously combined to create the ideal carbon-to-nitrogen ratio necessary for efficient decomposition. This initial stage requires precise fertilizer equipment for weighing, shredding, and mixing components to establish uniform consistency throughout the compost pile.

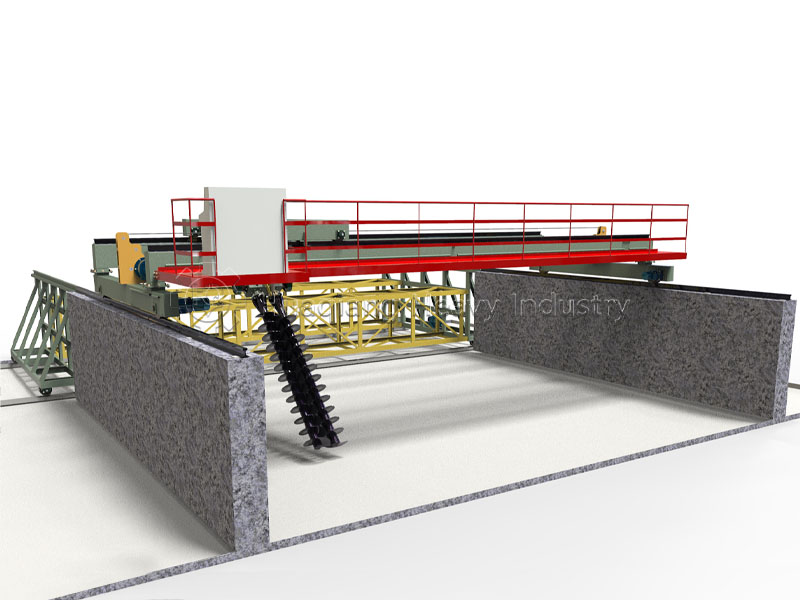

Central to this process is the compost fertilizer machine, which comes in various configurations tailored to different production scales and material characteristics. From small-scale windrow turners to industrial-grade in-vessel systems, each fertilizer production machine is engineered to create the optimal environment for microbial activity while minimizing labor requirements and processing time.

The complete suite of equipments required for biofertilizer production extends beyond simple composting tools. A modern facility incorporates a systematic approach with specialized machinery for each processing stage. The initial phase involves pre-processing equipment such as crushers, mixers, and screening machines that prepare raw materials for efficient decomposition.

These vital fertilizer machine units aerate the compost pile, regulate temperature, and ensure homogeneous decomposition. Advanced models feature automated control systems that monitor and adjust turning frequency based on real-time temperature and moisture readings.

Closed-system fertilizer equipment provides controlled environments for accelerated decomposition. These systems capture and treat emissions while maintaining ideal conditions for microbial communities, significantly reducing processing time compared to traditional open-windrow methods.

After active composting, specialized fertilizer production machine units screen, dry, and pelletize the mature compost into market-ready products. This stage ensures consistent particle size, moisture content, and nutrient distribution in the final organic fertilizer.

Modern compost fertilizer machine designs incorporate sophisticated features that dramatically improve efficiency and product quality. Sensor-based monitoring systems track critical parameters including temperature, oxygen levels, and moisture content, automatically adjusting operational parameters to maintain optimal composting conditions. These smart fertilizer equipment solutions minimize manual intervention while maximizing decomposition efficiency.

Another significant advancement in organic fertilizer production is the integration of resource recovery systems. Contemporary fertilizer production machine setups often include components that capture and reuse thermal energy generated during composting, reducing overall energy consumption. Some advanced facilities even incorporate leachate collection and treatment systems that recycle nutrient-rich liquids back into the composting process.

The selection of appropriate equipments required for biofertilizer production directly impacts both processing efficiency and final product quality. Industrial-scale operations typically employ in-vessel composting systems that offer superior process control compared to open methods. These enclosed fertilizer machine configurations maintain consistent temperatures and moisture levels while containing odors and preventing nutrient loss through leaching.

Post-composting processing represents another critical stage where specialized fertilizer equipment adds significant value. Screening machines separate fully decomposed material from larger particles that require additional processing. Grinding and pulverizing equipment then refines compost texture, while mixing and blending fertilizer production machine units incorporate supplemental nutrients or amendments to create customized fertilizer blends.

The evolution of organic fertilizer production technology has transformed composting from an artisanal practice into a precise scientific process. Modern fertilizer equipment and compost fertilizer machine innovations have dramatically improved processing efficiency, product consistency, and environmental performance. As agricultural systems worldwide increasingly prioritize sustainability, these advanced equipments required for biofertilizer production will play an increasingly vital role in closing nutrient cycles and supporting productive, regenerative farming practices.