2025-09-11

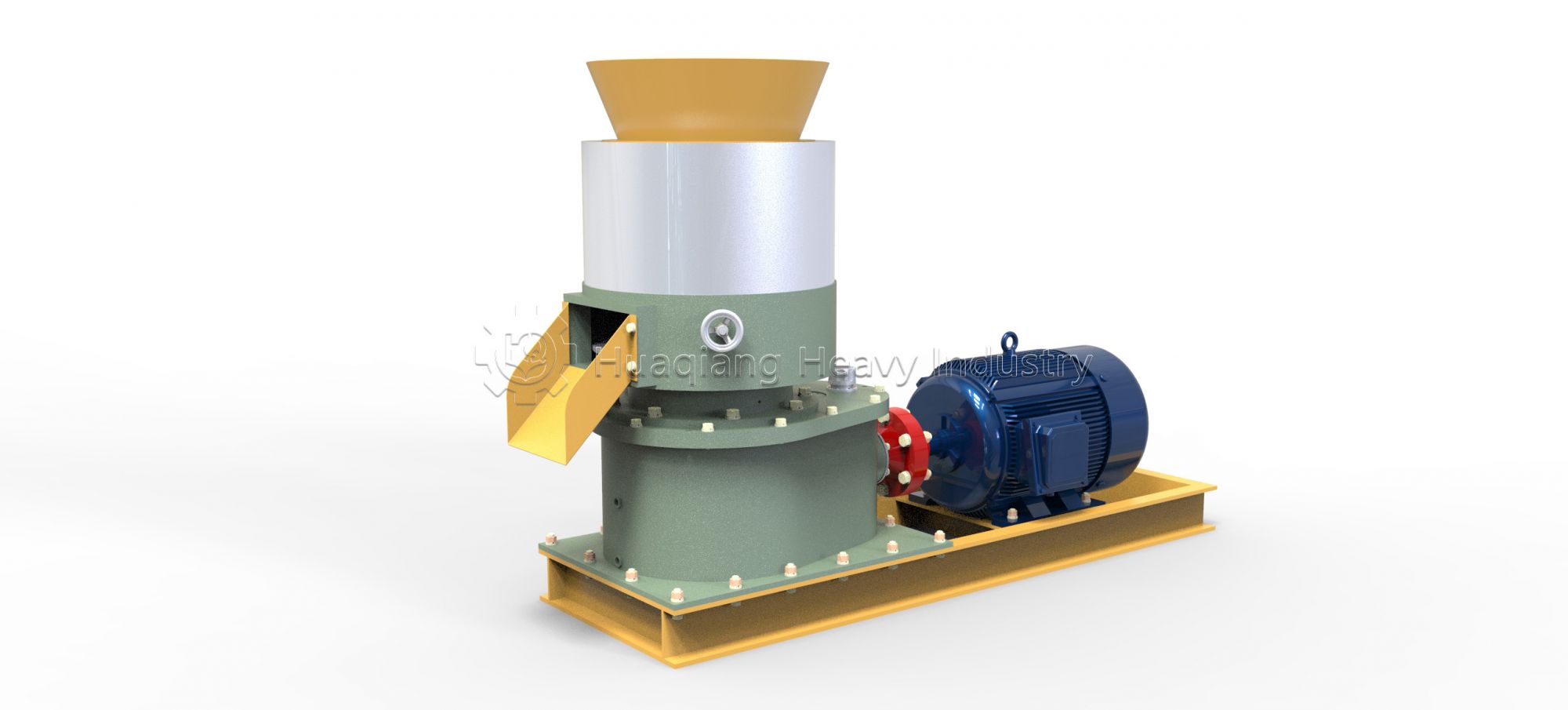

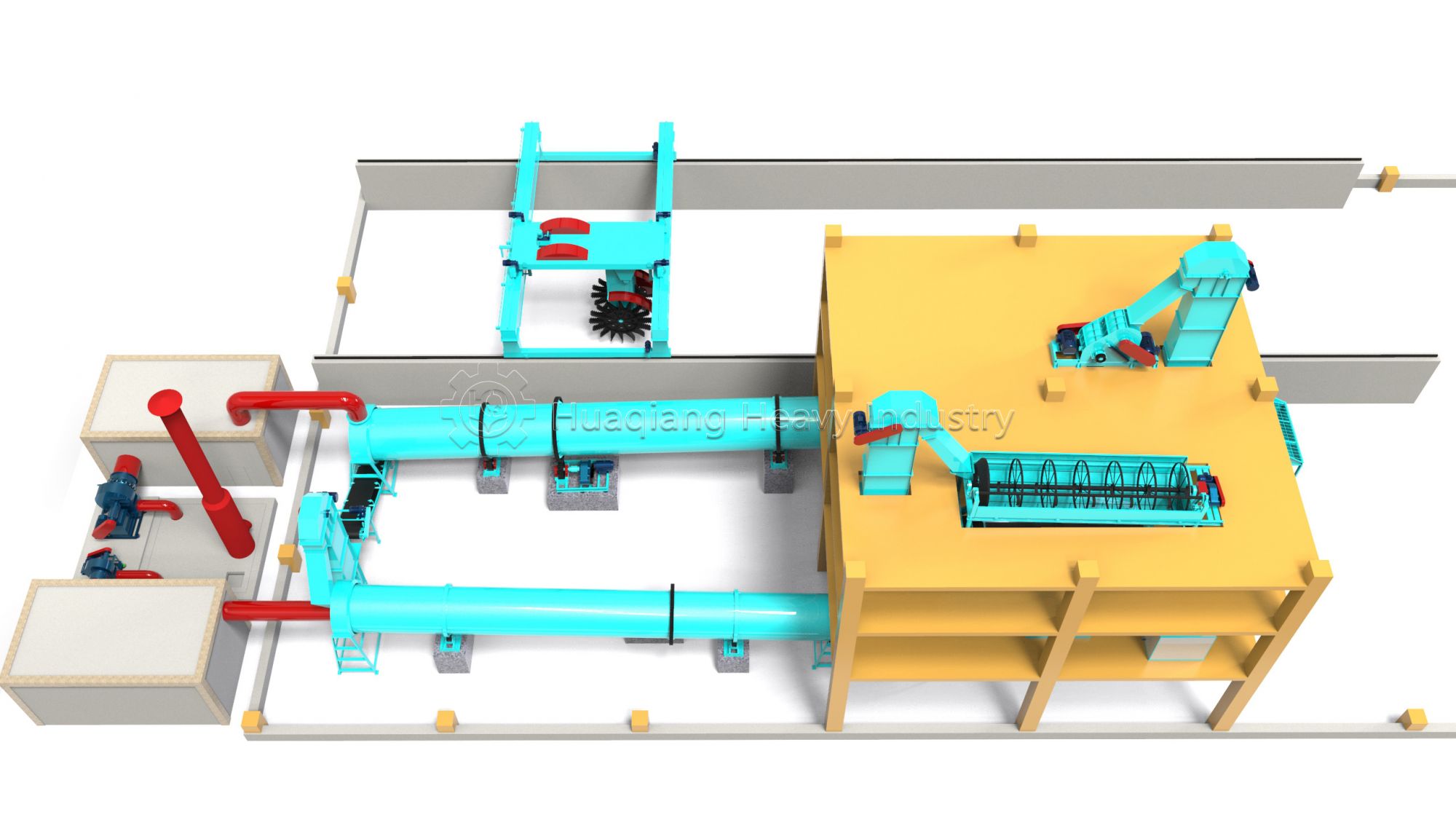

Flat die granulators play a pivotal role in fertilizer production. They convert organic waste like livestock manure and straw into high-value granular fertilizers, solving the pain points of caking and transportation difficulties with traditional organic fertilizers. More amazingly, by adjusting formulas, they can also produce specialized fertilizers like slow-release varieties to meet crops' nutritional needs at different growth stages.

In feed mills, flat die granulators mold ingredients like corn and soybean meal into perfect pellets. These pelleted feeds not only improve animal palatability but also reduce feed waste by 10-15%. From poultry to aquaculture, various breeding needs can be met.

Addressing energy transition needs, flat die granulators transform biomass materials like wood chips and straw into high-efficiency fuel pellets. These pellets boast 30-40% higher combustion efficiency than raw biomass with significantly lower emissions, making them ideal coal alternatives.

In fine chemical fields, flat die granulators ensure uniform forming of materials like plastics and pigments; in pharmaceuticals, they complete granulation without damaging drug activity, safeguarding medication quality. This precision processing capability makes them equally indispensable in advanced manufacturing.

From farm fields to modern factories, flat die granulators continue writing the legend of "turning waste into treasure" with their astonishing adaptability. This seemingly ordinary equipment is quietly transforming our production methods.