2025-07-08

Quality NPK blended fertilizers begin with scientific formulation design:

· Raw material selection: Purity of basic materials like urea, diammonium phosphate, and potassium chloride directly affects final quality

· Particle size matching: Similar particle sizes of components ensure uniform mixing and prevent segregation during transportation

· Formula calculation: Determine N-P-K ratios and micronutrient additions based on crop needs and soil conditions

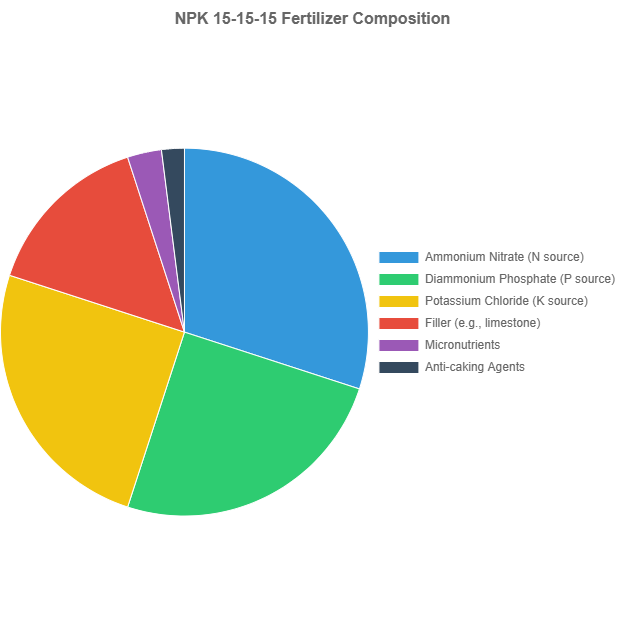

Typical ingredient ratio of NPK blended fertilizer (sample data)

Note: Example data showing typical composition ratios for NPK 15-15-15 blended fertilizer

Converting lab formulas to industrial production requires solving three key challenges:

1. Mixing uniformity: Large mixing equipment must ensure consistent distribution of components in each batch

2. Material flowability: Formulations must consider flow characteristics in conveying systems

3. Quality control: Establish complete inspection systems from raw materials to finished products

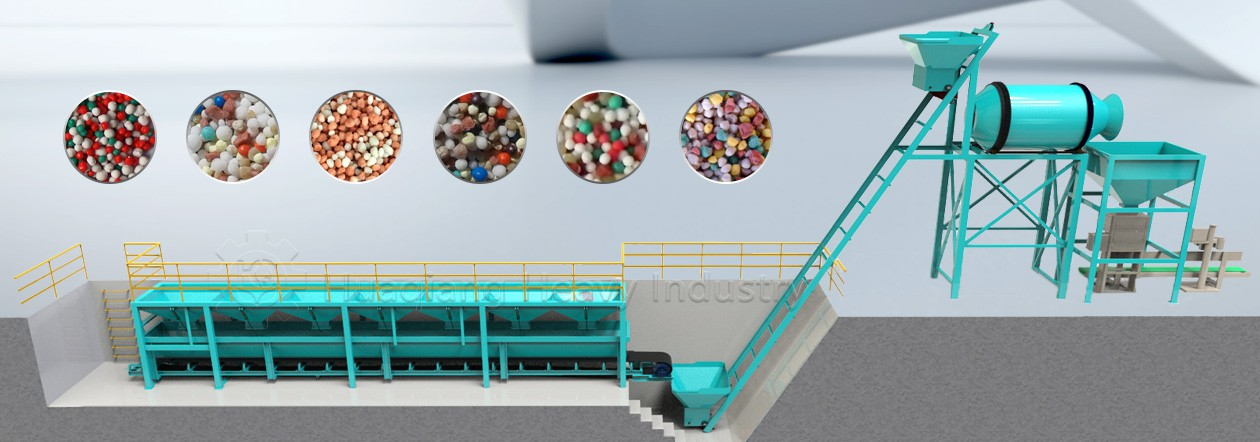

Typical NPK blended fertilizer production line

Cutting-edge NPK blended fertilizer production has developed various innovative models:

· Customized production: Adjust formulas in real-time based on farmers' soil test data

· Intelligent control: Use sensors and AI algorithms to optimize mixing parameters

· Modular design: Production lines can quickly switch between different formulations

According to FAO statistics, optimized blended fertilizer production lines can increase efficiency by 40% while reducing raw material waste by 15%.