In today's society, with the increasing awareness of environmental protection and people's pursuit of healthy food, the traditional agricultural model is facing unprecedented challenges. The excessive use of fertilizers and pesticides not only leads to the pollution of soil and water resources, but also affects the quality of agricultural products and people's health. Therefore, a new agricultural production method-

organic fertilizer production line came into being, bringing new hope for green development in agriculture.

The

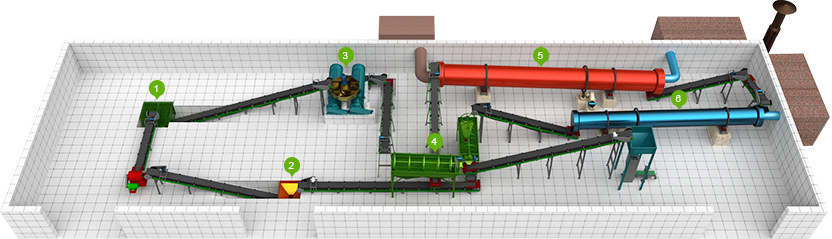

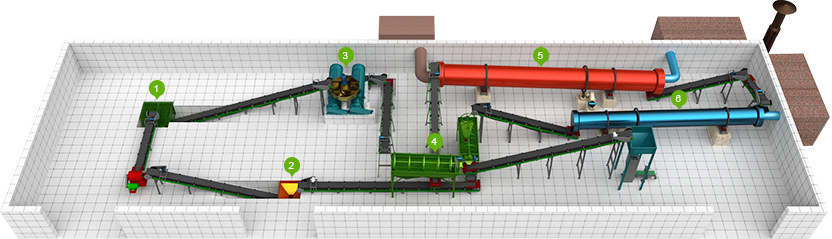

organic fertilizer production line is a complete set of process equipment and processes for converting organic waste into organic fertilizer. This production line includes components such as raw material pretreatment, fermentation, deep processing and auxiliary equipment, which can efficiently convert organic materials such as animal and plant residues and excrement into organic fertilizers rich in nutrients.

Raw material pretreatment equipment, such as crushers, mixers, etc., is used for pre-treatment of raw materials such as crushing, mixing and humidity adjustment. These equipment ensure that the raw materials can be evenly mixed, laying a good foundation for the subsequent fermentation process. Next, fermentation equipment such as composters and turners promote the reproduction of beneficial microorganisms by controlling environmental conditions such as temperature, humidity and oxygen, and convert organic waste into organic fertilizer. During this process, the turning machine regularly turns the materials to improve fermentation efficiency and remove moisture to ensure the smooth progress of the fermentation process.

The pre-treated raw materials will be sent to the granulation stage of the

organic fertilizer production line, and then they will be made into commercial organic fertilizer after drying, cooling and other steps.