2025-07-17

Quick tip before we dive in: The granulator is like the heart of your organic fertilizer production line. It takes all that prepared material and shapes it into market-ready pellets, affecting everything from nutrient content to how easy the fertilizer is to spread.

1. Ring Die Granulator - The Heavyweight Champion

· How it works: Uses a rotating ring die with internal rollers to squeeze material through holes - think of it like a giant playdough machine

· Pros: High output (we're talking tons per hour), produces super uniform pellets, handles moderate moisture well

· Cons: Big footprint, higher power consumption, not great for sticky materials

· Best for: Commercial-scale operations where consistency and volume matter most

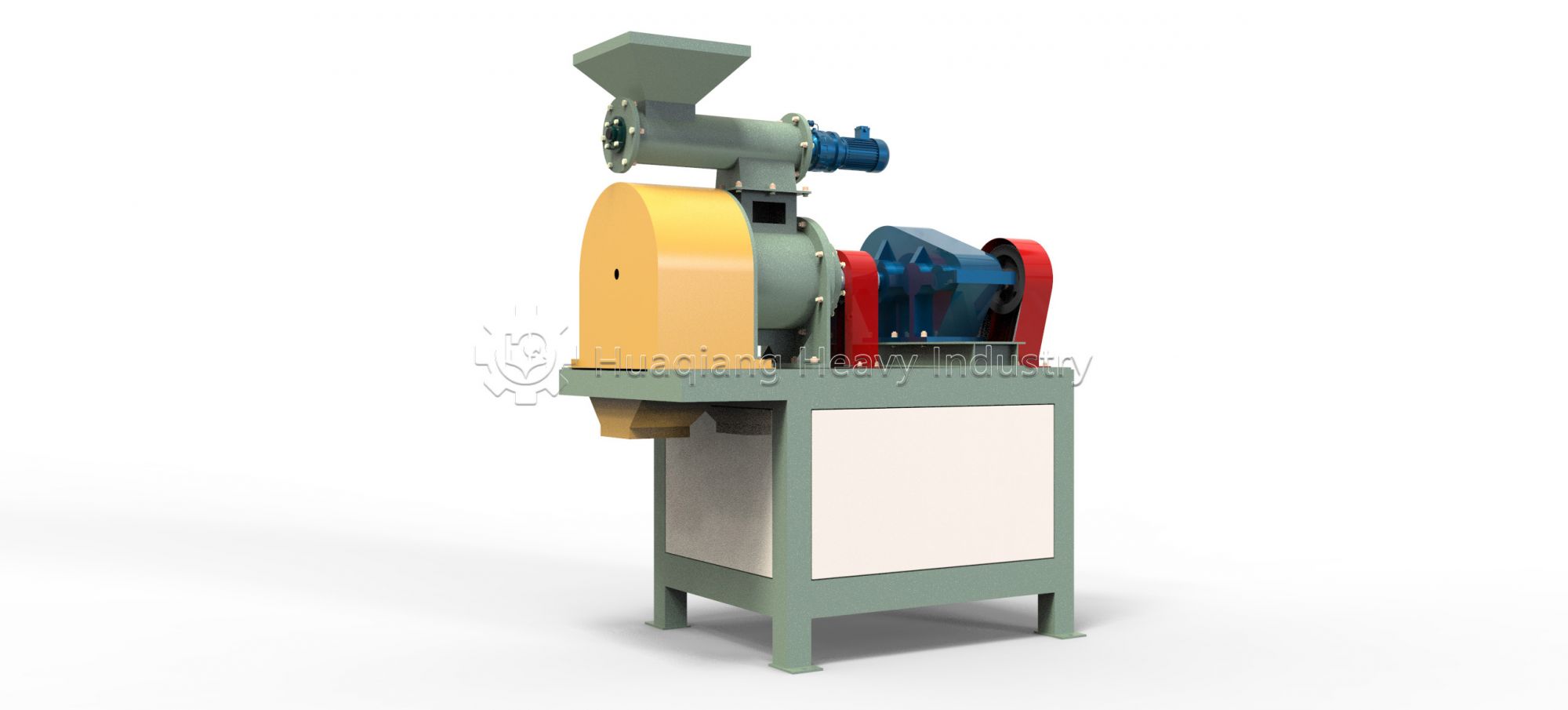

2. New Type Organic Fertilizer Granulator - The Versatile Performer

· How it works: Combines crushing and granulating in one unit using a unique stirring and shearing action

· Pros: Handles diverse materials (even fibrous stuff), lower energy use, compact design

· Cons: Slightly less uniform particle size than ring die, not ideal for very wet materials

· Best for: Medium operations processing mixed organic wastes (like farm waste + food scraps)

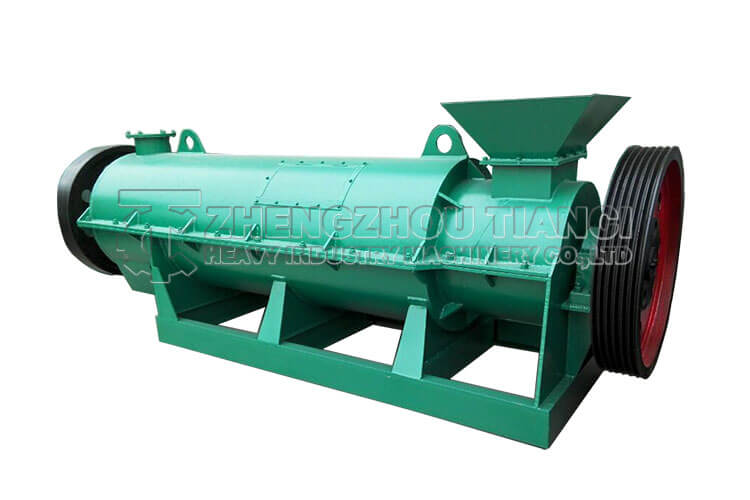

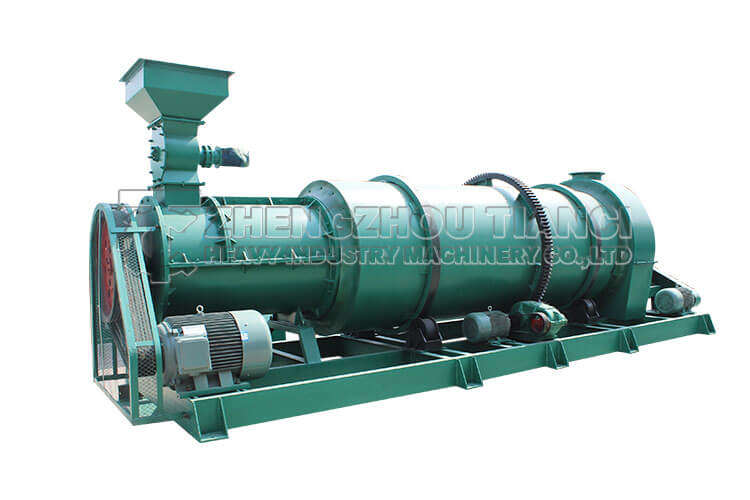

3. New Type Stirring Tooth-Drum Granulator- The Space Saver

· How it works: Integrates fermentation and granulation in a single drum - basically does two jobs at once

· Pros: Saves floor space, reduces handling between processes, good for continuous production

· Cons: Requires careful moisture control, smaller batches than dedicated granulators

· Best for: Startups or urban farms where space is tight but you want complete processing

4. Flat Die Granulator - The Reliable Workhorse

· How it works: Material gets compressed between a flat die and rollers - simpler version of ring die

· Pros: Affordable, easy to maintain, good for small batches

· Cons: Lower output, dies wear faster than ring types

· Best for: Small farms making fertilizer for own use or local sales

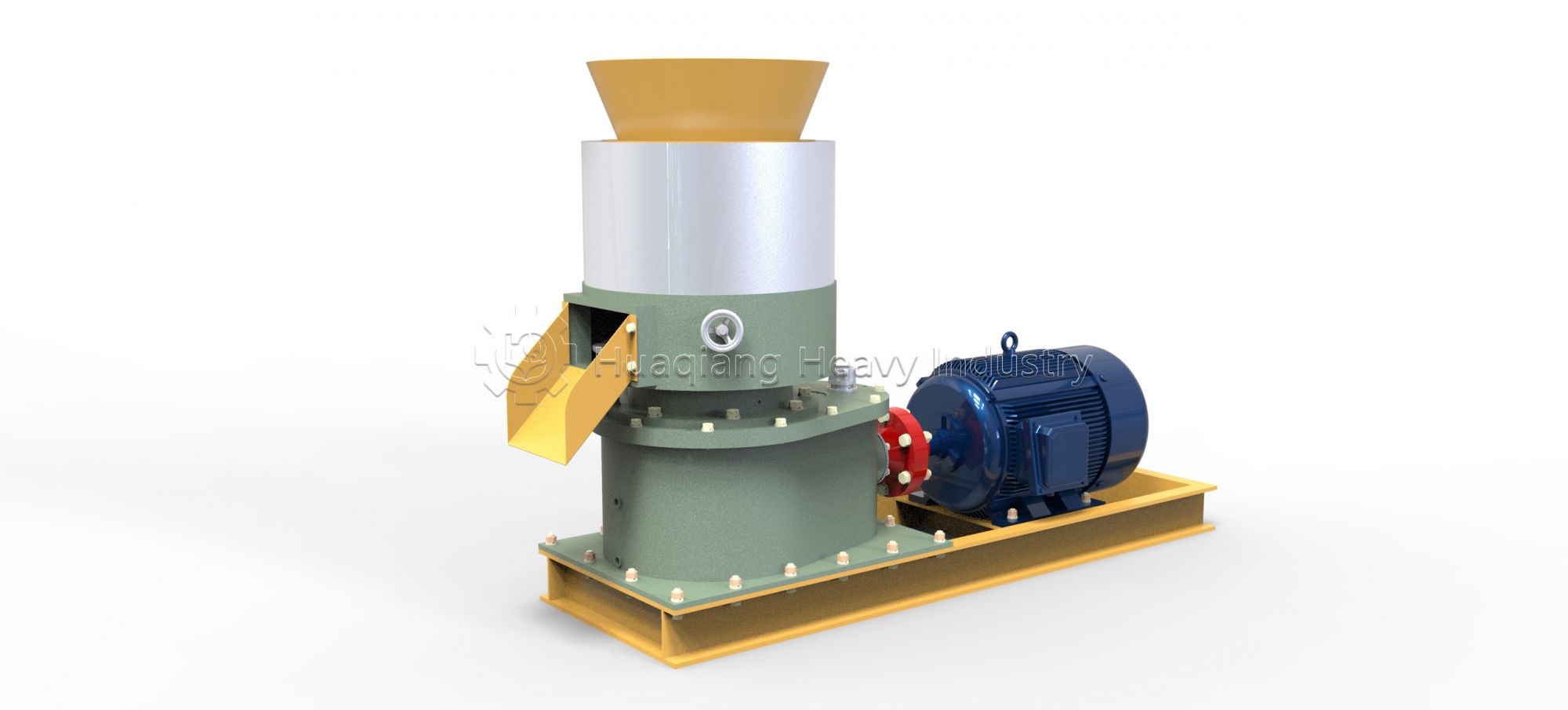

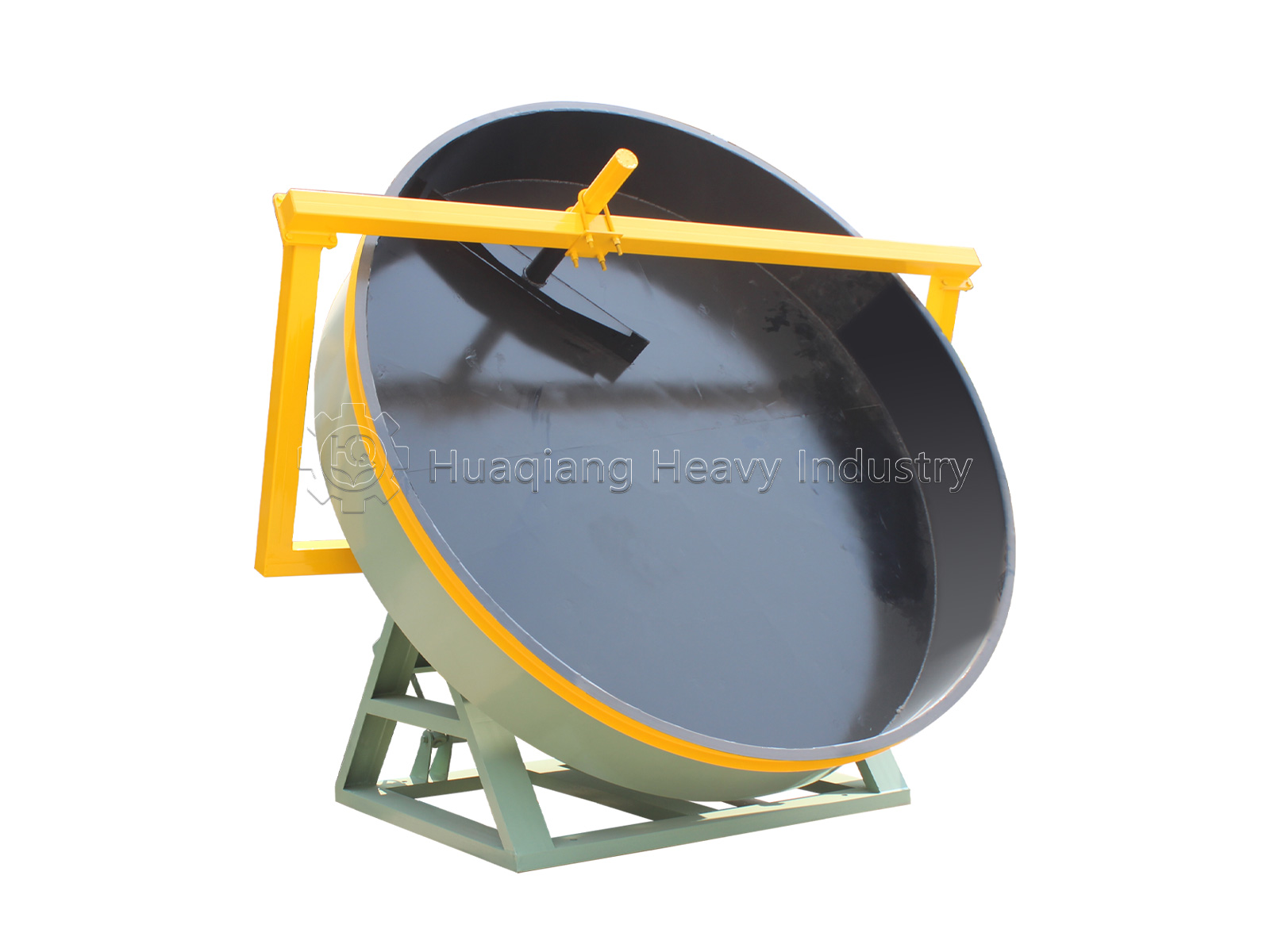

5. Disc Granulator - The Gentle Giant

· How it works: Material tumbles in an inclined rotating disc, forming perfect little spheres

· Pros: Produces beautiful round pellets, gentle on delicate materials, adjustable disc angle controls size

· Cons: Needs binder for some materials, not as compact as other types

· Best for: Premium organic fertilizers where pellet appearance matters (think horticulture or retail products)

In a typical organic fertilizer production line, granulation happens after composting and material prep but before drying and packaging. The machine you choose affects:

· How you prepare materials beforehand (crushing size, moisture content)

· Your drying requirements (some granulators handle wetter materials better)

· Final product quality (density, crush resistance, dissolution rate)

At the end of the day, there's no "best" granulator - just the one that best fits your specific materials, production goals, and budget. The good news? With these five options, you're almost guaranteed to find your perfect match!