Today, Huaqiang Heavy Industry will briefly introduce the pre-treatment stage of

organic fertilizer production by biological organic fertilizer manufacturers.

1. Raw material selection and pretreatment:

The raw materials can be organic waste such as agricultural waste (such as straw), urban domestic waste, livestock and poultry manure, food processing waste, etc.

The selection of raw materials needs to consider factors such as its moisture content, carbon-nitrogen ratio (C/N ratio), and biodegradability.

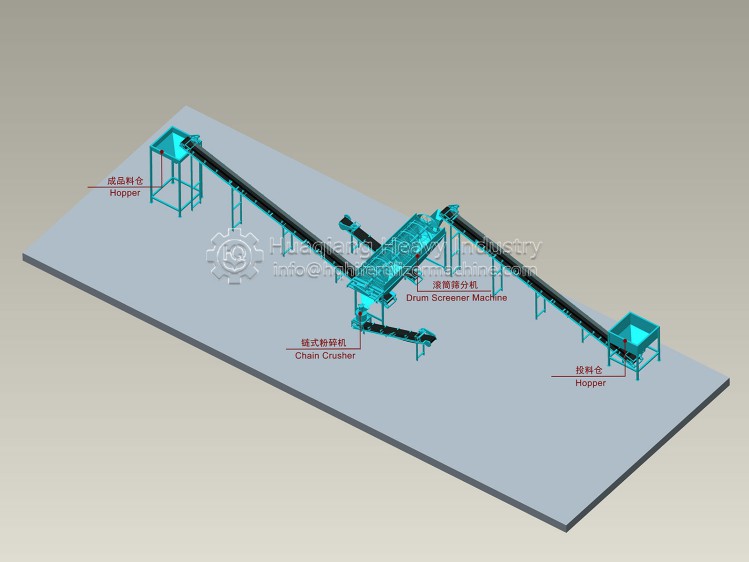

Pretreatment includes debris removal, crushing, and adjusting moisture and C/N ratio. The particle size of the crushed raw materials should be appropriate, generally controlled at 12 to 60 mm, so that microorganisms can reproduce and ferment better.

Adjust the moisture to the appropriate range, usually 55% to 65%, which can be judged by holding the material tightly in the hand to form a ball, and water marks appear but do not drip out.

2. Mixing and batching:

Mix the pretreated raw materials with organic biological fermentation compound bacteria (add 1-2 kg per ton of raw materials) in proportion.

When the

biological organic fertilizer manufacturer mixes the ingredients, it is necessary to first dissolve the brown sugar in water, then add the organic fertilizer fermentation bacteria and stir thoroughly, then sprinkle the diluent evenly on the raw materials, and stir thoroughly with a mixer.

Adjust the C/N ratio of the raw materials to an appropriate range, generally 20:1 to 30:1, to ensure the smooth progress of the fermentation process.

The

biological organic fertilizer manufacturer needs to pre-treat the raw materials to produce organic fertilizers, and the specific operation details will also be different for different raw material formulas. If you are interested in this, please contact Huaqiang Heavy Industry.