2025-09-30

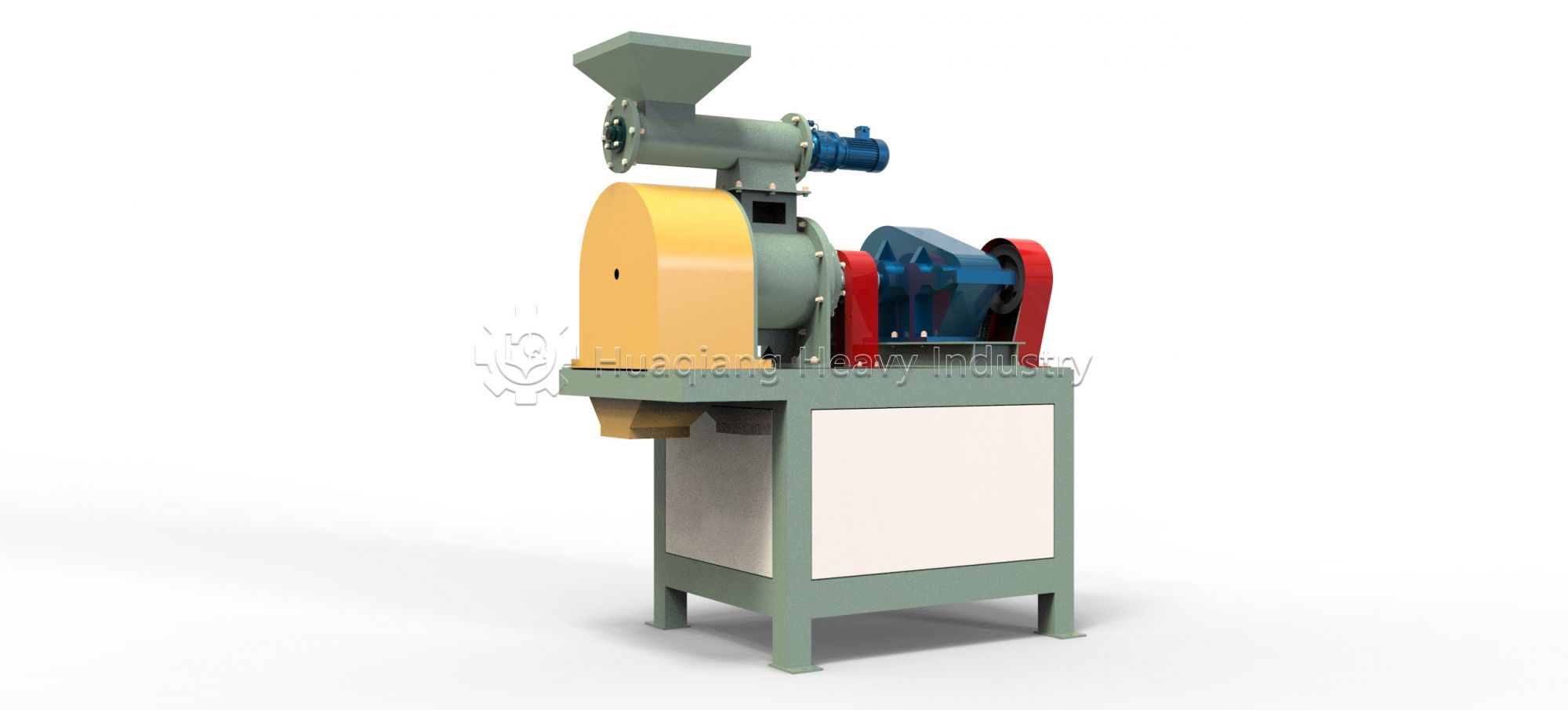

While rotary drum granulators utilize a tumbling motion for agglomeration and roller press granulators employ high-pressure compaction, the ring die granulator stands out for organic fertilizer applications. Its unique mechanism provides superior control over fertilizer granules compaction, ensuring consistent density and size distribution. This makes it particularly suitable for organic materials that require specific handling characteristics.

As a specialized organic fertilizer production machine, the ring die granulator demonstrates remarkable versatility in processing diverse organic compounds while maintaining structural integrity. The machine's precision engineering allows for customized pellet specifications, making it the preferred choice for high-quality organic fertilizer production where product uniformity and nutrient preservation are paramount.

The process begins with a 1-10 cubic meter "raw material warehouse" - the hopper. The screw conveyor functions like a precision belt, delivering materials at infinitely variable speeds through frequency control. The conditioner acts as a "material beautician," using steam or binders to achieve optimal plasticity, with humidity controlled within ±0.5% accuracy.

This cylinder made of high-strength alloy steel boasts surface hardness of HRC55-65, 3-5 times more wear-resistant than regular steel. Its inner wall contains precision holes (2-20mm diameter) with fluid-optimized layouts ensuring uniform pressure distribution. Like a strict sculptor, it shapes consistent pellets - each hole serving as its artistic chisel.

2-3 patterned rollers press materials firmly into the die with 0.1mm gap precision, handling everything from organic fertilizer to mineral compounds. Made of alloy steel, these rollers last 3000-5000 hours - double the lifespan of cast iron versions.

High-speed alloy blades cut extruded columns to specified lengths with surgical precision. Operating at 200-500 RPM with 0.1mm positioning accuracy, this system ensures every pellet meets strict dimensional standards - like an experienced barber giving perfect "haircuts" to pellets.

The 15-160kW motor, through reduction gearing, converts high-speed rotation into stable low-speed operation. Frequency control allows stepless speed adjustment between 5-30 RPM to accommodate different materials. This system serves as the equipment's heart and nervous system, ensuring all components work in harmony.