2025-07-10

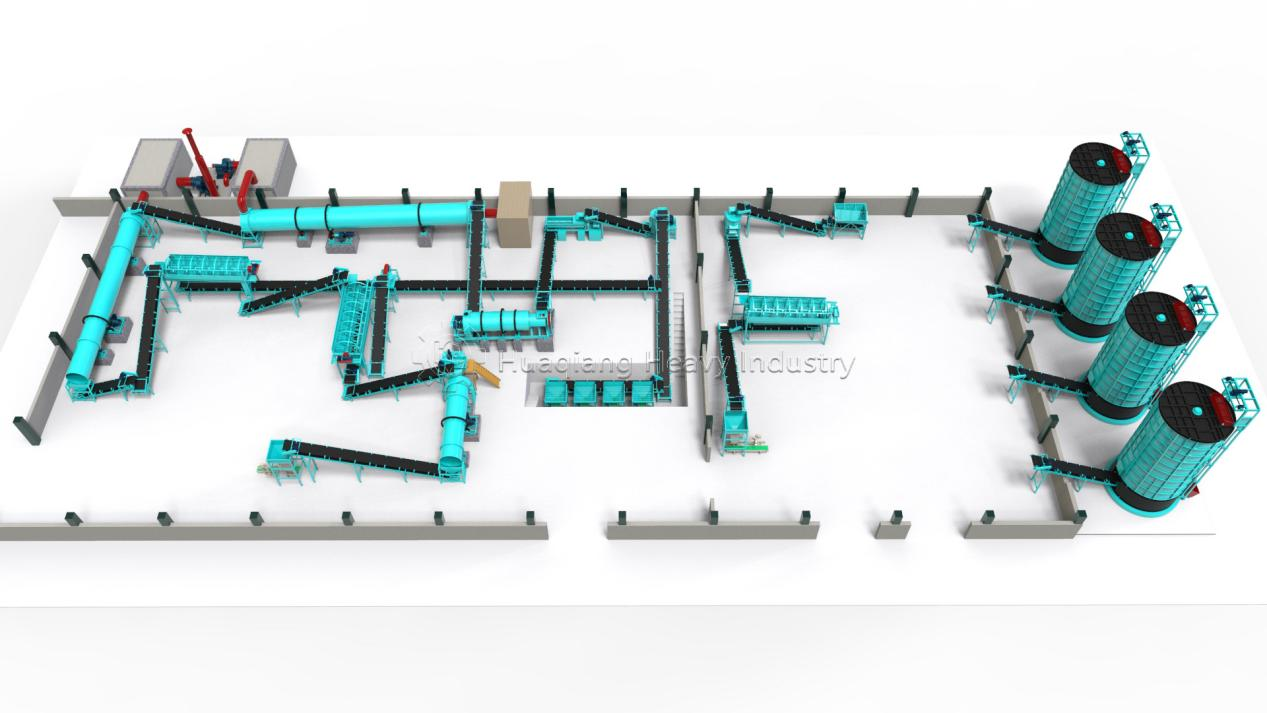

The introduction of the New Type Organic Fertilizer Granulator represents a significant advancement in the organic fertilizer production process, as it enhances granulation efficiency, reduces energy consumption, and improves product quality. This innovation seamlessly integrates into a modern fertilizer production line, replacing outdated equipment and streamlining operations—from raw material pretreatment to drying and packaging—thereby optimizing the entire system's productivity and sustainability while promoting circular agriculture through organic waste utilization.

The New Type Organic Fertilizer Granulator plays a pivotal role in modern fertilizer production lines by transforming organic waste into uniform, high-quality granules. Its innovative design combines mixing, granulating, and polishing in one efficient process, significantly streamlining organic fertilizer production.

Key advantages include high granulation rate (>85%), ability to process moist materials (30-40% water content) without pre-drying, and adjustable particle size (0.3-5mm) through simple speed controls. It excels with fine organic materials like manure and agricultural byproducts, producing denser, more stable granules than conventional methods.

Choosing this granulator means lower energy consumption, reduced production costs, and higher-quality organic fertilizer with preserved nutrient content. Its efficiency and flexibility make it ideal for sustainable fertilizer operations seeking to optimize both productivity and environmental benefits.

This revolutionary equipment utilizes powerful mechanical stirring force and friction generated by high-speed rotation to complete the entire process of mixing, granulation, spheroidization, and strengthening in a single unit. Its most notable advantage over conventional equipment is the ability to directly process raw materials with moisture content as high as 30%-40%, completely eliminating the energy-intensive pre-drying stage.

Production data shows this machine achieves a granulation rate exceeding 85%, producing particles ranging from 0.3-5mm in diameter while maintaining exceptionally high organic content. Operators can precisely control particle size by adjusting material input and spindle speed - lower input with higher speed yields smaller particles, providing customized solutions for different applications.

The equipment excels at processing lightweight fine powders like poultry manure (chicken, pig, cattle) and industrial byproducts such as carbon black, clay, and kaolin. Interestingly, finer raw material powders result in better pellet formation rates and higher quality granules, making it ideal for processing refined organic waste.

From an environmental perspective, this technology not only improves organic waste utilization but also significantly reduces energy consumption in production, perfectly aligning with global sustainability trends. For organic fertilizer producers seeking transformation and upgrading, this represents a technological innovation well worth investing in.