The biogas sludge

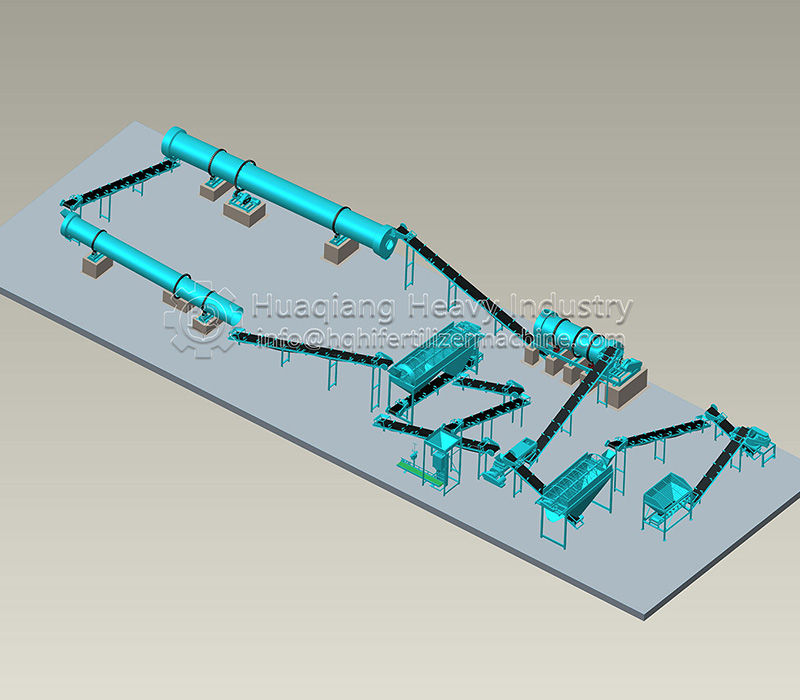

organic fertilizer production line is a production line that converts organic waste such as biogas sludge and sludge into organic fertilizer. So, what is the process flow of the biogas sludge organic fertilizer production line?

1. Raw material collection and pretreatment: Collect organic waste such as biogas sludge and sludge, and carry out necessary pretreatment, such as removing impurities and adjusting moisture, to ensure the smooth progress of subsequent processes.

2. Fermentation and decomposition: The pretreated raw materials are sent to the fermentation equipment for fermentation and decomposition. During the fermentation process, microorganisms will decompose organic matter, generate heat and carbon dioxide, etc., so that the raw materials are gradually converted into stable organic fertilizers.

3. Crushing and mixing: The fermented and decomposed materials are crushed and mixed with other additives (such as inorganic fertilizers, microbial agents, etc.) to ensure the nutrient balance of the fertilizer and the uniformity of the particles.

4. Granulation and molding: The mixed materials are sent to the granulator for granulation and molding. The

fertilizer granulator can adjust the size and shape of the particles as needed to meet the needs of different users.

5. Drying and cooling: The granulated fertilizer is sent to the dryer for drying to remove excess water. The dried fertilizer needs to be sent to the cooler for cooling to prevent the fertilizer from agglomerating during storage and transportation.

6. Screening and packaging: The cooled fertilizer is screened to remove unqualified particles. Qualified fertilizer is packaged for storage and transportation.

The above is the process flow of the sludge

organic fertilizer production line compiled by Huaqiang Heavy Industry. If you have any related questions, please feel free to contact us.