2022-02-08

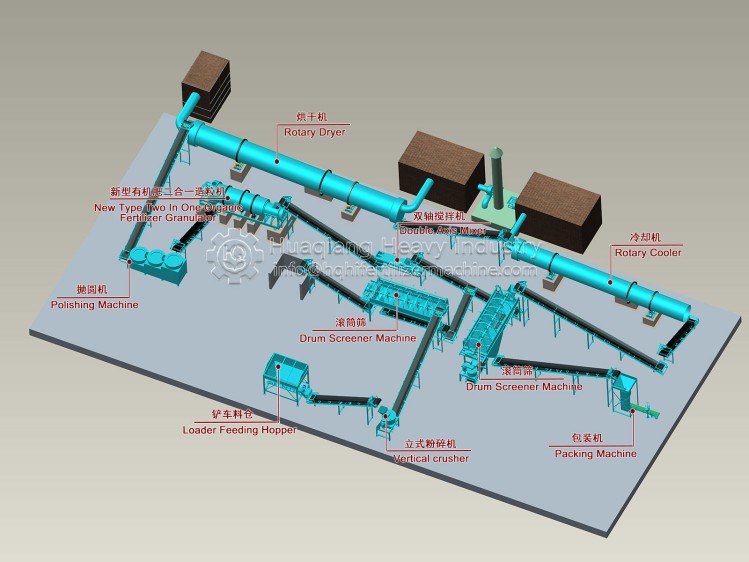

1. Organic fertilizer Dumper: directly pile the materials into strips, and use a wheeled dumper to turn and ferment in a straddle manner. Tank fermentation is adopted. According to your production scale, you need to build 1-5 fermentation tanks with a width of 3M and a length of 40-60m. The fermentation products are continuously put into the fermentation tank and tossed and fermented by the tossing machine, which can achieve the purpose of water regulation, uniform mixing, deodorization and dehumidification, which can not only save a lot of labor, but also achieve the purpose of full ripening;

2. Organic fertilizer screening machine: screen the fermented organic fertilizer and separate the large pieces and sundry fibers inside, which is convenient for the crushing, granulation and packaging of semi wet materials in the next step.

3. Organic fertilizer granulator: granulate the materials after crushing and stirring;

4. Organic fertilizer crusher: separate the large debris and stones in the screened organic fertilizer and crush them, which is beautiful and can ensure the quality of products;

5. Organic fertilizer dryer: dry and cool the prepared particles;

6. Automatic packaging machine: granulate organic fertilizer particles and directly package and sell them.