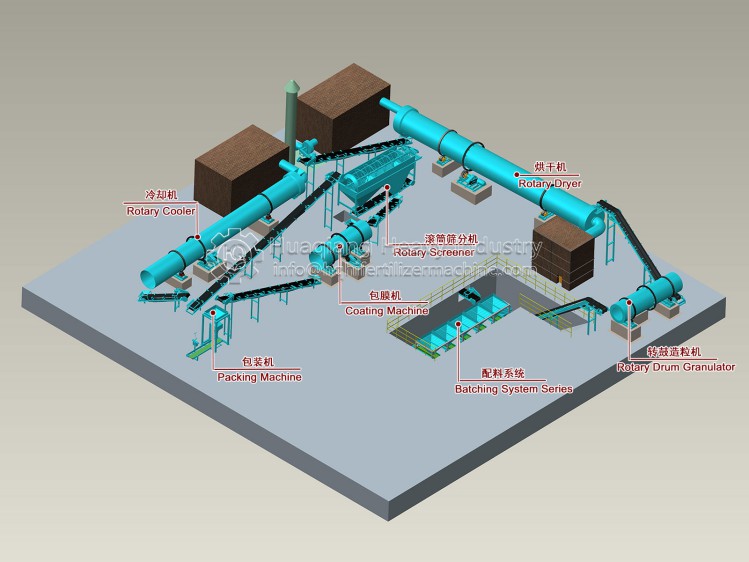

We are a professional fertilizer equipment manufacturer. We design and produce various fertilizer machines. According to the characteristics of the process and raw materials of roller press granulator, we have designed a roller press granulator fertilizer production line. This kind of roller press granulator fertilizer production line takes into account the characteristics of raw materials, and follows the principle of low consumption, which is very economical and practical.

Single axis urea crusher

The single axis urea crusher is a cage crusher. It can crush all kinds of fertilizers with water content below 40%, especially for materials with high hardness. The grinding granularity of single axis urea crusher meets the granulation requirement of roller press granulator.

Horizontal mixer

Horizontal mixer mixes materials in batches. The materials can be completely mixed and the mixing speed is fast. Horizontal mixer has a large mixing capacity, which can ensure the full mixing of materials.

Disc feeding machine

The feeding speed is controlled to facilitate the entry of raw materials into the roller press granulator.

Roller press granulator extrudes the raw materials fed by disc feeding machine into granules. Roller press granulator has good granulating effect on the heat sensitive compound fertilizer, and other trace elements can be added to the raw material to improve the fertilizer efficiency.

The drum screener has a good effect in sieving granules and uses a combined screen for easy maintenance and replacement.

Packing machine

The packing machine will pack the compound fertilizer granules quantitatively. Packing machine realizes automatic sewing and other operations, greatly reducing human labor.

This small roller press granulator fertilizer production line has the advantages of small area, low processing cost, very low production energy consumption and no pollution. It is a very practical and economical fertilizer production line suitable for small and medium-sized fertilizer plants.