2025-06-23

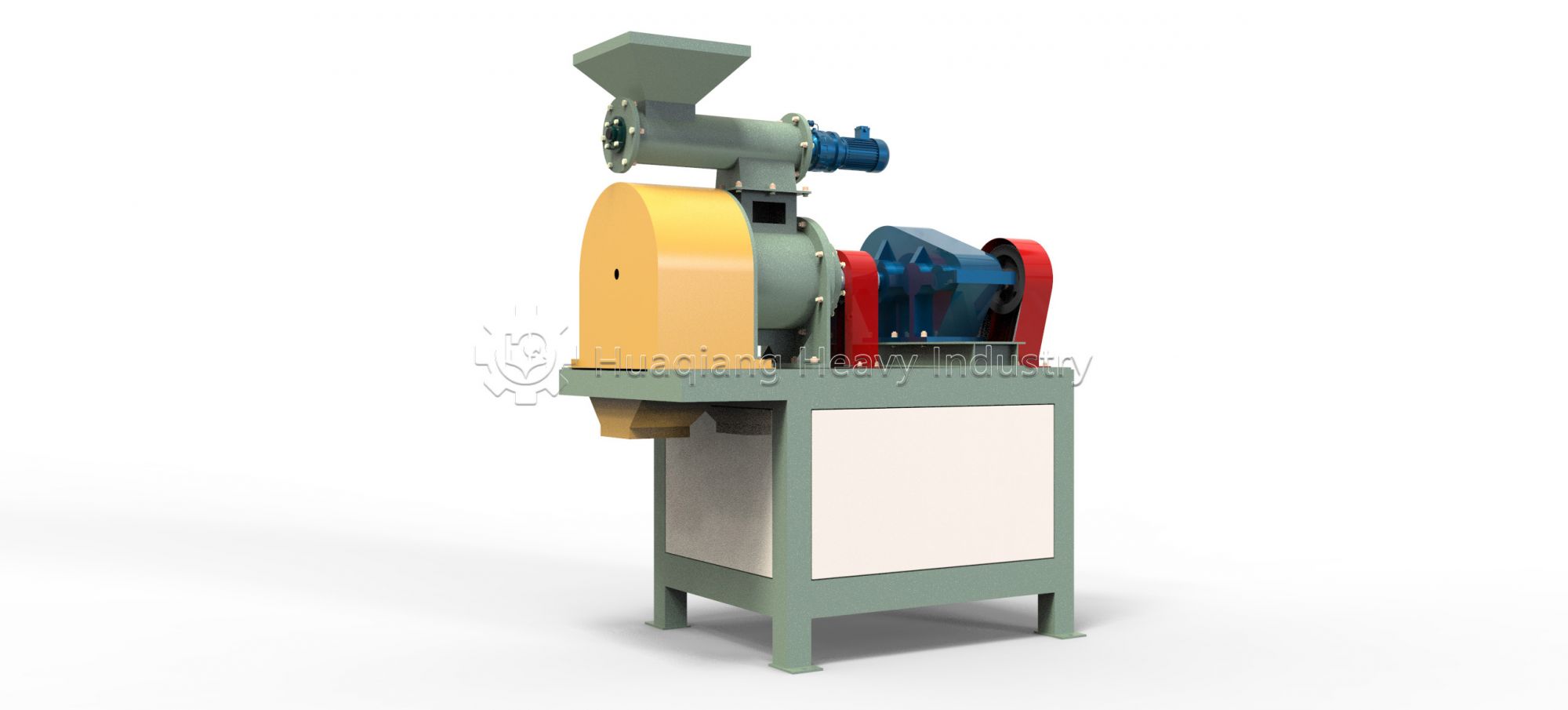

ring-die granulator

The granulation process is a key stage in organic fertilizer production, mainly achieving the following functions:

· Transforming powdered raw materials into granules, reducing dust loss during application

· Increasing product bulk density, lowering packaging and transportation costs

· Improving fertilizer physical properties, enhancing market competitiveness

· Facilitating control of nutrient release rate, improving utilization efficiency

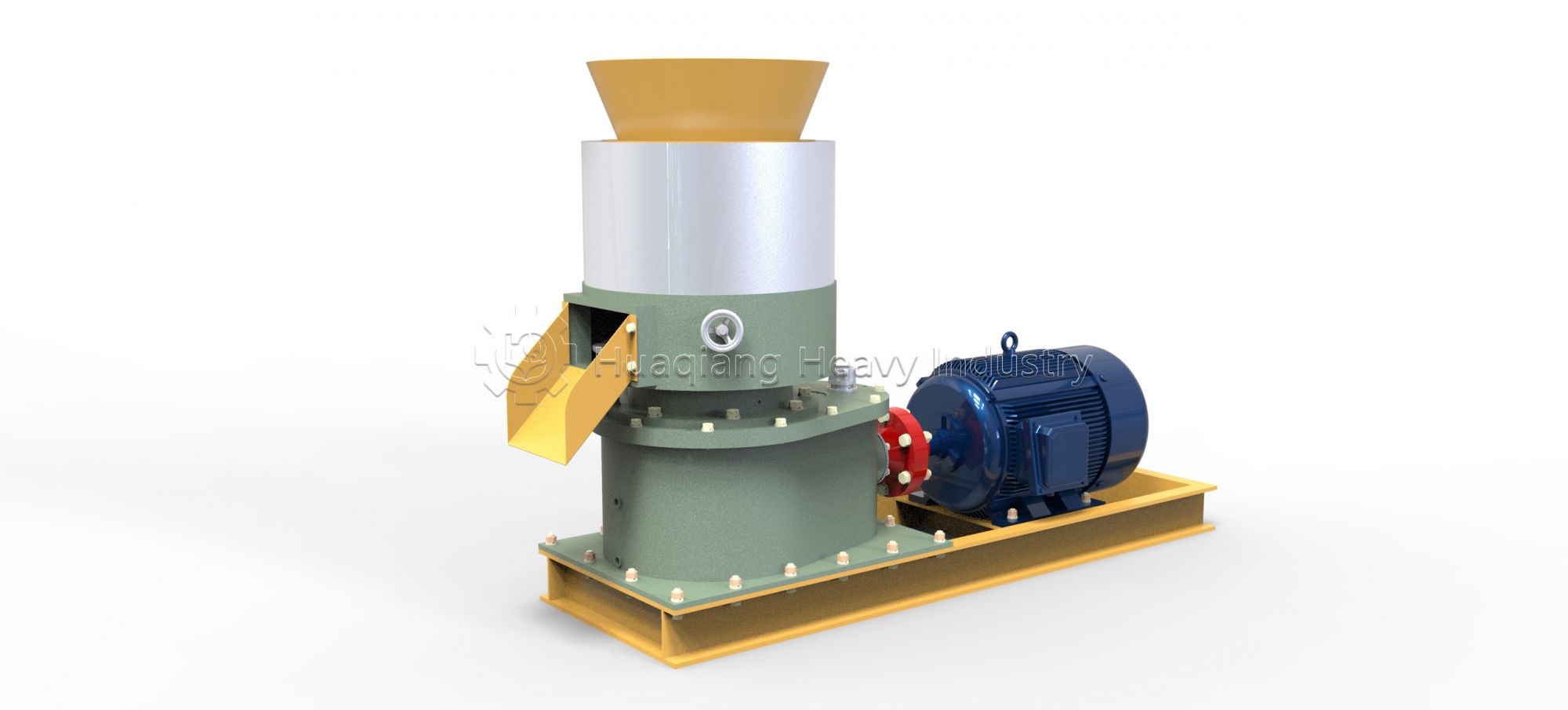

flat-die granulator

|

Comparison Item |

ring-die granulator |

Flat-Die Granulator |

|

Working Principle |

Two counter-rotating dies extrude the material |

Material is extruded between flat die and pressure roller |

|

Capacity Range |

3-15 tons/hour |

1-8 tons/hour |

|

Pellet Shape |

Cylindrical, smooth surface |

Irregular shape, rougher surface |

|

Energy Consumption |

Higher |

Lower |

|

Maintenance Cost |

Higher |

Lower |

|

Suitable Materials |

Fine powder, low fiber content |

Fibrous, sticky materials |

When to choose ring-die granulator:

· Pursuing high output and large-scale production

· Raw materials mainly fine powder with low fiber content

· Need to produce pellets with exquisite appearance

· Strict requirements on pellet uniformity

When to choose flat-die granulator:

· Small to medium scale production with limited budget

· Raw materials contain more fibers or sticky substances

· Less demanding on pellet shape

· Emphasis on equipment operating economy

As an expert in the organic fertilizer equipment sector, the company has developed a series of innovative granulation technologies:

· Intelligent Dual-Mode Granulator: Equipped with an automatic pressure regulation system, reducing energy consumption by 15%.

· Multifunctional Flat-Die Granulator: Capable of processing various organic raw materials, with a switching time of only 30 minutes.

· Composite Granulation Production Line: Combining the advantages of the two technologies above to meet a wider range of production needs.

Since its establishment in 2005, the company has been dedicated to the R&D and manufacturing of organic fertilizer equipment, providing customers with complete solutions from raw material pretreatment to packaging. Our equipment is renowned for its efficiency, environmental friendliness, and intelligence, having helped more than 300 enterprises worldwide establish modern organic fertilizer production lines. Whether you require dual-mode or flat-die granulation technology, we can offer the most suitable customized solutions to ensure your investment achieves optimal returns.