2026-02-12

When planning to build a new or upgrade an existing fertilizer production line, a crucial choice often arises in the core granulation stage: should you choose the classic, widely adaptable rotary drum granulator, or invest in the energy-efficient and increasingly popular double roller press granulator? These two types of equipment represent two fundamentally different technological approaches, and the choice directly determines your production capacity ceiling, energy costs, and the market competitiveness of your final product. Understanding their underlying principles is the first step in making a wise investment decision.

Technical Essence: The Fundamental Difference Between Chemical Reaction and Physical Forming

The core difference between these two types of equipment lies in the completely different ways they give "shape" to the materials.

The rotary drum granulator (usually referring to a drum granulator) is an agglomeration process that relies on thermodynamics and chemical reactions. The mixed powdered raw materials are fed into a large, slowly rotating drum, while steam or a binder liquid is simultaneously sprayed in. During the drum's rotation, the fine powder, under the binding action of the liquid phase (slurry), gradually agglomerates into spheres through repeated rolling and collision, like "rolling a snowball." This process requires high chemical reactivity of the materials and is particularly suitable for producing mainstream high-concentration compound fertilizers and blended fertilizers (BB fertilizers). The resulting granules are round, have moderate strength, and good dissolution characteristics.

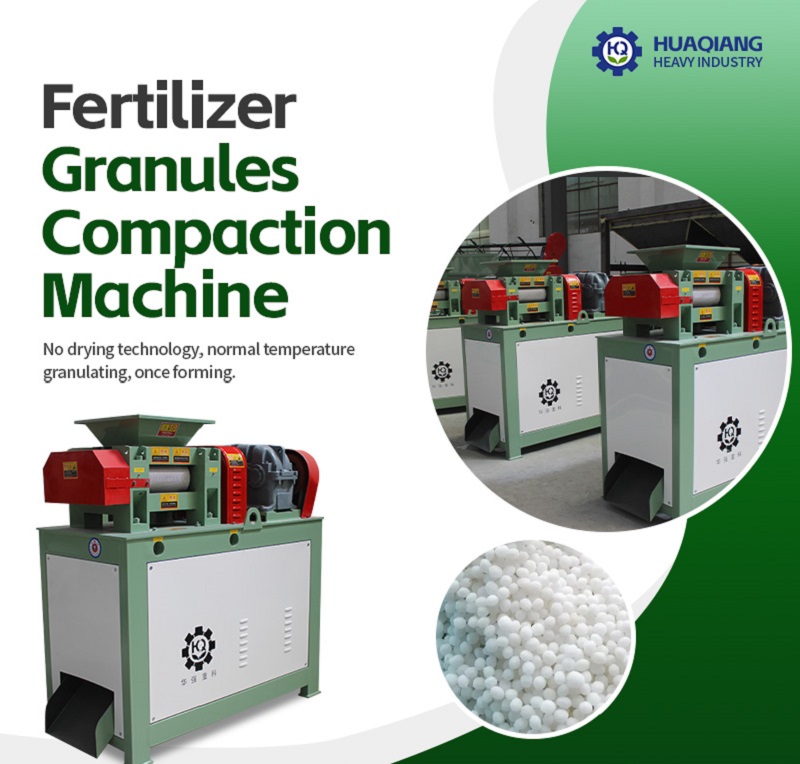

The double roller press granulator, on the other hand, is a purely high-pressure physical forming process. It feeds completely dry powdered raw materials between a pair of precisely machined and synchronously counter-rotating rollers. Under linear pressure of tens to hundreds of tons, the material is forcibly squeezed through the die holes on the roller surface, forming dense, regular flat or pillow-shaped granules. This process does not require the introduction of water or heat, making it particularly suitable for producing organic-inorganic compound fertilizers, heat-sensitive bio-fertilizers, and certain special fertilizers that are prone to unfavorable chemical reactions.

Capacity and Efficiency: Choosing the Path of Economies of Scale and Energy Saving

When evaluating "which equipment can increase production," it is essential to consider both absolute capacity and overall efficiency.

In terms of achieving large-scale, continuous production, the rotary drum granulator has a traditional advantage. The design capacity of a single large rotary drum granulator can be very high, easily matching large-scale compound fertilizer production lines with an annual output of hundreds of thousands of tons, offering significant economies of scale. However, this high capacity comes at the cost of high energy consumption – it requires a large steam boiler, dryer, and cooling system, and the thermal energy consumption of the entire system accounts for a considerable proportion of the total cost.

Double-roll press granulators demonstrate revolutionary advantages in energy saving and overall efficiency. Due to their "room temperature molding" characteristics, they completely eliminate the drying process, saving approximately 30%-50% of fuel costs, and produce almost no exhaust gas, resulting in less environmental pressure. For small and medium-sized factories or factories producing specialty fertilizers, this means lower operating costs and greater product flexibility. Capacity increases are usually achieved by increasing the width of the press rolls or using multiple units in parallel. While the absolute peak capacity may not be as high as large rotary drums, their energy consumption and cost per unit of output are more competitive.

Selection Decision: Matching Your Raw Materials, Scale, and Market

The final choice should be strictly based on your production raw materials, factory scale, and product positioning.

If you are a large-scale compound fertilizer manufacturer, primarily using chemical powders as raw materials, pursuing maximum output under a single formula, and already have infrastructure such as steam, then the mature, stable, and high-yield characteristics of the rotary drum granulator remain your most reliable choice.

If you are an organic fertilizer producer, a specialty fertilizer company, or a medium-sized compound fertilizer plant, your raw materials may include fermented organic matter or heat-sensitive components, and you are highly sensitive to energy consumption and product differentiation, then the double-roll press granulator will be a powerful tool to help you reduce costs, increase efficiency, and create distinctive products. It is especially suitable for processing high-nitrogen, high-salt index formulations that are difficult to granulate with rotary drums.

Maintenance and Long-Term Value

In terms of maintenance, the focus of rotary drum granulator maintenance is on the rotating parts, lining plates, and transmission system, and the maintenance of its drying system is also relatively complex. Maintenance of the double-roll press granulator is highly concentrated on the core press roll assembly. Wear of the press rolls and molds is the main ongoing cost, but its modular design usually makes maintenance more direct and faster. In short, rotary drum granulators are "capacity giants" for achieving large-scale standardized production, while double-roll press granulators are "efficiency experts" focused on energy saving and differentiated production.

There is no single best equipment; only the solution that best suits your strategy. In today's manufacturing landscape, driven by the "dual carbon" goals and the green transformation, choosing a double-roll press granulator may not only mean increased current output but also represent a forward-looking strategy for future production cost control and product structure upgrading. Before making a decision, the best approach is to conduct small-scale trials using your typical raw materials, allowing the data to guide you towards the path that will best improve your "output" and "efficiency."

Integrating Granulation Technologies for Strategic Advantage

The evolution of fertilizer granulation technology has given producers the ability to choose between fundamentally different approaches. Drum granulation, utilizing a rotary drum granulator, remains the workhorse for large-scale wet agglomeration, leveraging chemical reactions and steam to create round, dense particles. Conversely, the double roller press granulator represents a paradigm shift in fertilizer production machine technology, achieving dry fertilizer granules compaction through high mechanical pressure. For a forward-thinking company, the optimal strategy may not be an exclusive choice, but a hybrid approach. A production line could integrate a rotary drum granulator for high-volume standard NPK products and a dedicated double roller press granulator line for energy-efficient, specialty, or organic-inorganic blends. This dual-technology capability allows manufacturers to maximize economies of scale while simultaneously capturing premium market segments with differentiated, low-energy products, building a more resilient and competitive business model.