2026-02-11

In NPK compound fertilizer production, granulation technology is a core link that determines product quality and economic efficiency. Drum granulation and high-tower granulation, as the two main process routes today, are based on different physicochemical principles, resulting in distinct technical characteristics and application scopes.

Drum Granulation: A Flexible and Versatile Classic Process

Process Principles and Characteristics

Drum granulation is essentially a mechanical agglomeration process, belonging to the wet granulation category. Its working principle involves feeding precisely proportioned powdered raw materials (urea, ammonium phosphate, potassium chloride, etc.) into a rotating drum with a certain inclination angle. As the drum rotates at a constant speed, the materials continuously tumble and slide under gravity, forming complex motion trajectories.

The key control point lies in the precise injection of steam. When saturated steam at approximately 130-150°C is evenly injected into the material layer, it produces a triple effect: firstly, it causes partial dissolution of soluble salts such as urea and ammonium nitrate on the surface, forming a viscous liquid film; secondly, it provides latent heat to raise the temperature of the material, promoting eutectic reactions between the salts; and finally, it increases the plasticity of the material, reducing the molding resistance. During the continuous tumbling motion, fine powder particles bond together through liquid bridge forces and capillary forces, growing layer by layer like a "snowball," ultimately forming spherical granules of 1-4.75 mm.

Technical Advantages and Application Scenarios

The biggest advantage of drum granulation is its excellent process flexibility. Because the granulation process mainly relies on physical agglomeration, it has a very wide range of adaptability to raw material formulations, allowing the production of various product ratios from low concentration (such as 25-5-10) to high concentration (such as 17-17-17), making it particularly suitable for compound fertilizer production that requires frequent formula changes.

In practical applications, a drum granulation line with a design capacity of 15 tons/hour can switch production between various products such as corn-specific fertilizer (e.g., 28-6-6) and fruit and vegetable-specific fertilizer (e.g., 15-5-25) in a short time, requiring only adjustments to the raw material ratio and a few process parameters. This flexibility makes it the preferred choice for companies serving regional markets and producing a wide variety of specialized fertilizers.

Product Characteristics and Quality Control

Drum granulation products are characterized by high particle hardness (compressive strength usually ≥20N), a relatively rough surface, and a wide particle size distribution. The high hardness of the particles ensures a low breakage rate during transportation, storage, and mechanical fertilization. By controlling parameters such as steam volume, drum rotation speed, and inclination angle, the particle compactness and dissolution rate can be adjusted.

Production data from a compound fertilizer company in Henan Province shows that its drum granulation production line has an annual capacity of 100,000 tons and can produce more than 20 different product formulations. The average granulation rate is 92%, and the average particle compressive strength is 25N, fully meeting the requirements for mechanized fertilization.

High-Tower Granulation: An Efficient and Advanced Process

Process Principles and Engineering Characteristics

High-tower granulation is a physicochemical process, belonging to melt granulation technology. Its core principle is to heat a high-concentration nitrogen source (usually urea or ammonium nitrate) to a completely molten state (urea at approximately 133°C, ammonium nitrate at approximately 170°C), and then uniformly mix it with preheated phosphorus and potassium raw materials to form a highly fluid, high-temperature melt.

The key engineering aspects are the atomization and cooling of the melt. The melt is pumped to the top of the granulation tower (usually 60-120 meters high) via a high-pressure pump and atomized into fine droplets by a specially designed rotating nozzle. These droplets fall freely within the tower, counter-currently contacting cold air entering from the bottom, rapidly cooling and solidifying to form nearly perfect spherical particles. The entire process fully utilizes the surface tension of the melt for natural granulation and the ample cooling time provided by the high-altitude fall.

Technical Advantages and Applicable Conditions

The most significant advantages of high-tower granulation are superior product quality and energy efficiency. Because no additional water is involved in the granulation process, the product has a very low moisture content (usually <0.5%), and the particles have a smooth, rounded surface with a natural anti-counterfeiting pore structure. These pores make the product dissolve 30%-50% faster than ordinary granules.

More importantly, the high-tower process can produce compound fertilizers with nutrient concentrations exceeding 50% (such as 30-5-15), which is difficult to achieve with other processes. However, this advantage comes at the cost of significant initial investment – a complete high-tower granulation plant typically costs 2-3 times more than a drum granulation line of equivalent capacity, and is more suitable for large-scale continuous production of a single formula.

Product Characteristics and Market Positioning

Granules produced by high-tower granulation have a unique hollow or porous structure, with low density but moderate strength, and disintegrate rapidly in water. This characteristic is particularly suitable for top-dressing applications requiring rapid effect. A large fertilizer company in Shandong Province has a high-tower production line specifically producing several standard formulas such as 17-17-17 and 15-15-15, with an annual capacity of 300,000 tons. Thanks to their excellent appearance and dissolution performance, these products command a high premium in the high-end market.

Comprehensive Considerations for Technology Selection

Investment and Operating Cost Analysis

Drum granulation has relatively low initial investment, with a 100,000-ton/year production line costing approximately 15-25 million RMB. Steam consumption is the main component of its operating costs, accounting for about 60-70% of total energy consumption. However, the flexibility of formulas means it can better adapt to market demand changes, reducing the risk of unsold products.

High-tower granulation has a high initial investment, requiring 40-60 million RMB for equivalent capacity, with the construction cost of the granulation tower itself accounting for a large proportion. In operation, the melting process consumes a significant amount of energy, but the drying step is eliminated, resulting in overall energy consumption roughly comparable to the drum process. Its economic benefits come from large-scale production and product premium.

Key Factors in Selection Decisions

Product Strategy: If the company is positioned in the multi-variety, small-batch specialty fertilizer market, drum granulation is a better choice; if it focuses on large-scale production of a few high-concentration general-purpose fertilizers, high-tower granulation has an advantage.

Raw Material Conditions: The availability of a stable and inexpensive supply of urea or ammonium nitrate locally is a prerequisite for considering the high-tower process.

Financial Strength: The high investment threshold of the high-tower process makes it more suitable for large companies with strong financial resources.

Market Demand: Markets with specific requirements for granule appearance and dissolution speed may prefer high-tower products.

Development Trends and Innovation Directions

Currently, both technologies are developing towards intelligence and green production. Drum granulation, by incorporating online particle size analyzers and automatic control systems, achieves real-time optimization of process parameters; high-tower granulation, through a heat recovery system, utilizes the waste heat from the melting and cooling processes for raw material preheating, reducing energy consumption by more than 15%.

It is worth noting that some innovative processes, such as spray granulation and chemical granulation, are combining the advantages of both. Spray granulation involves preparing a portion of the raw materials into a slurry and spraying it onto recycled granules, offering both formula flexibility and product quality; chemical granulation directly granulates through the heat generated by chemical reactions between the raw materials, resulting in even lower energy consumption.

Drum granulation and high-tower granulation represent two different directions in NPK compound fertilizer granulation technology, each with its own scientific basis and applicable scenarios. Drum granulation excels in flexibility and is a powerful tool for the production of diverse specialty fertilizers; high-tower granulation wins in quality and efficiency, making it the preferred choice for large-scale standard fertilizer production. Companies should choose the most suitable technological path based on their product positioning, financial strength, and market environment. In the future, with technological advancements, the boundaries between the two processes may gradually blur, and integrated and innovative processes will bring more possibilities to compound fertilizer production.

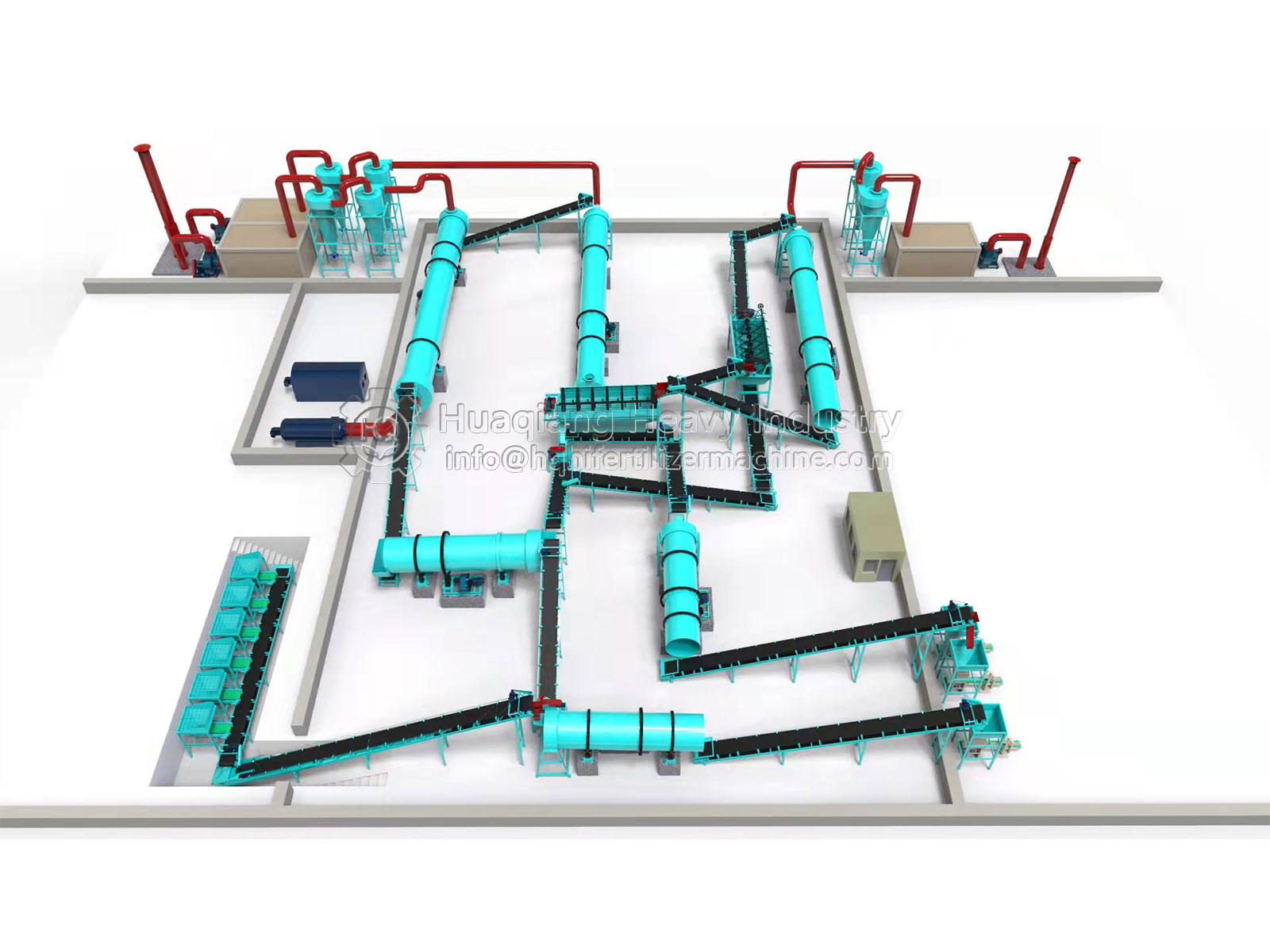

Beyond the classic drum and tower processes, modern npk fertilizer production technology encompasses a wider array of fertilizer production machine technology. A highly efficient rotary drum granulator is often preceded by a homogenizing fertilizer horizontal ribbon mixer to ensure uniform raw material blend. For dry granulation, a roller press granulator production line utilizes a fertilizer compactor (a type of fertilizer compaction machine) to achieve fertilizer granules compaction without heat or liquid binders. For producing premium spherical organic or compound fertilizers, a disc granulator for shaping is a core component. For small-scale or specific pellet shapes, a flat die pelleting machine offers a cost-effective solution. This diverse technological toolkit allows producers to select the optimal granulation method based on raw material properties, product specifications, and economic considerations, ensuring efficiency and product quality.