Raw material storage yard: Used to store raw materials such as pig manure. Generally, it is necessary to build a site with a length of 100 meters, a width of 30 meters, and a height of 4 meters, and equipped with rain and sun protection facilities to keep the raw materials dry and stable.

Fermentation equipment: Fermentation tank or fermentation pool, used for fermentation treatment of raw materials. You can choose a hydraulic trough turner for fermentation and turning of materials, which has the advantages of high accumulation of fermented materials, large turning output, and thorough turning of materials.

Compost turning machine: Such as a trough turner or a mobile turner, which is used to regularly turn over the fermenting materials to promote uniform fermentation.

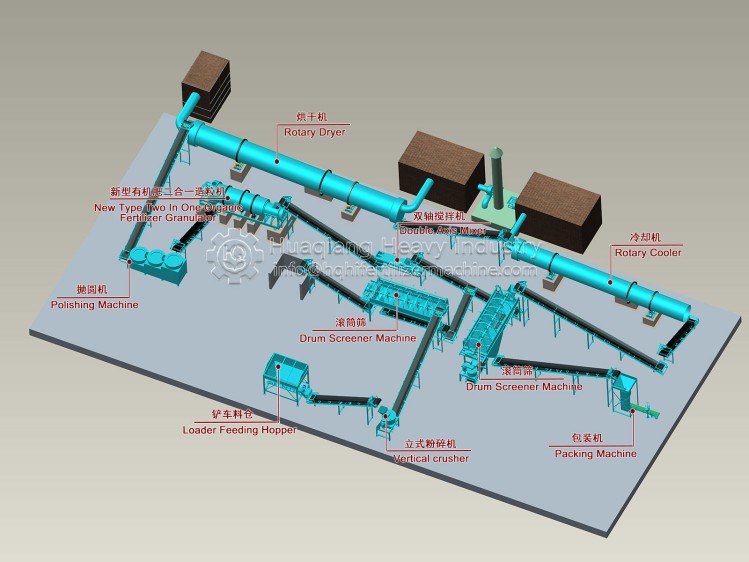

Crushing equipment: Crusher, used to crush the fermented pig manure into fine particles for subsequent mixing and packaging. You can choose a double-axis horizontal crusher, which has a reasonable structure, easy installation, high efficiency, durability, and simple maintenance.

Mixing equipment:

Fertilizer mixer, used to fully mix the crushed pig manure and necessary additives (such as microbial agents) to ensure the uniformity of the fertilizer. Generally, a double-shaft mixer or a vertical mixer is used.

Screening equipment: Screening machine, used to screen the mixed materials, remove large pieces and debris, and improve product quality.

Packaging equipment: Automatic packaging scale, used to weigh and package the screened powdered organic fertilizer for easy storage and sales.