2025-09-04

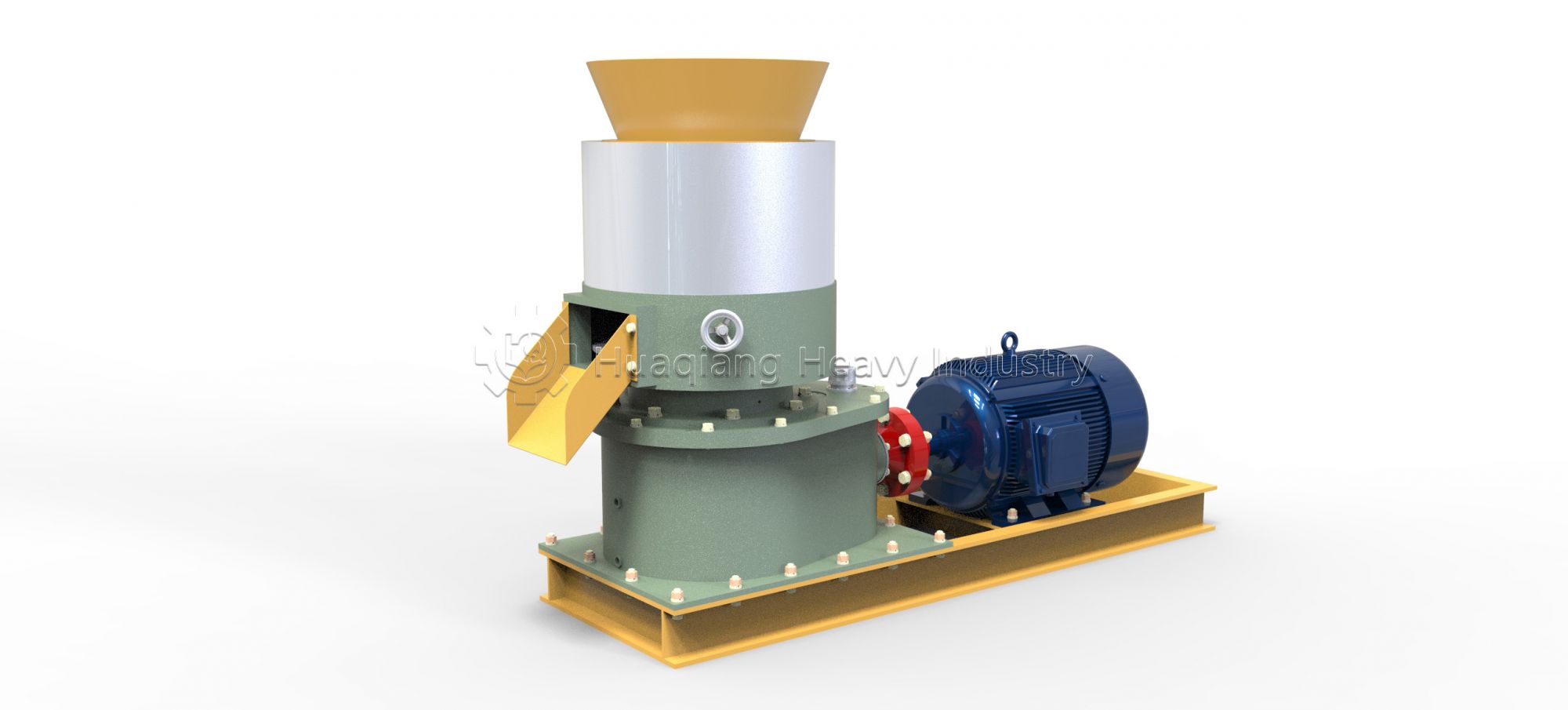

Walking into any modern fertilizer plant, you'll witness the industrial ballet of a flat die granulator. This core organic fertilizer manufacturing machine expertly performs fertilizer granules compaction, transforming powdery organic materials into dense, uniform granules. As the heart of the organic fertilizer production machine line, it choreographs compression and extrusion through its flat die, turning raw waste into valuable, market-ready fertilizer with remarkable efficiency.

Before the granulation journey begins, raw materials undergo a "deep beauty treatment." Organic materials like livestock manure and straw first complete a 30-45 day fermentation "sauna," then are ground into 80-100 mesh powder as fine as baby powder. For compound fertilizer ingredients, elements like NPK are measured with bartender-like precision, requiring over 90% mixing uniformity and moisture content strictly controlled within the golden range of 15%-25%.

The pretreated materials enter the granulator's "pressure chamber." Here, rotating rollers apply 10-30MPa of pressure (equivalent to 300kg concentrated on a coin-sized area), forcing material through precision holes in the flat die. The equipment operates at an elegant 10-30 RPM, like an experienced potter shaping clay into perfect forms.

The extruded columns immediately meet rotating blades, being precisely cut into 2-8mm granules with length variations under 0.5mm. These newborn granules then enter the "beauty pageant" - vibrating screening system. Oversized or undersized particles get eliminated and returned for reprocessing, while only perfectly sized granules advance.

Freshly made granules undergo final "setting." Air cooling systems gently lower temperatures like a natural breeze, preventing particle adhesion from residual heat. The cooled granules are automatically measured and packaged, ready to begin their mission of nourishing crops and improving soil.