2025-09-03

In modern chemical and agricultural industries, disc granulators play a vital role. This seemingly simple equipment performs the magic of transforming loose powder into uniform pellets, significantly improving material utilization efficiency and transportation convenience. But how exactly does this machine accomplish this transformation?

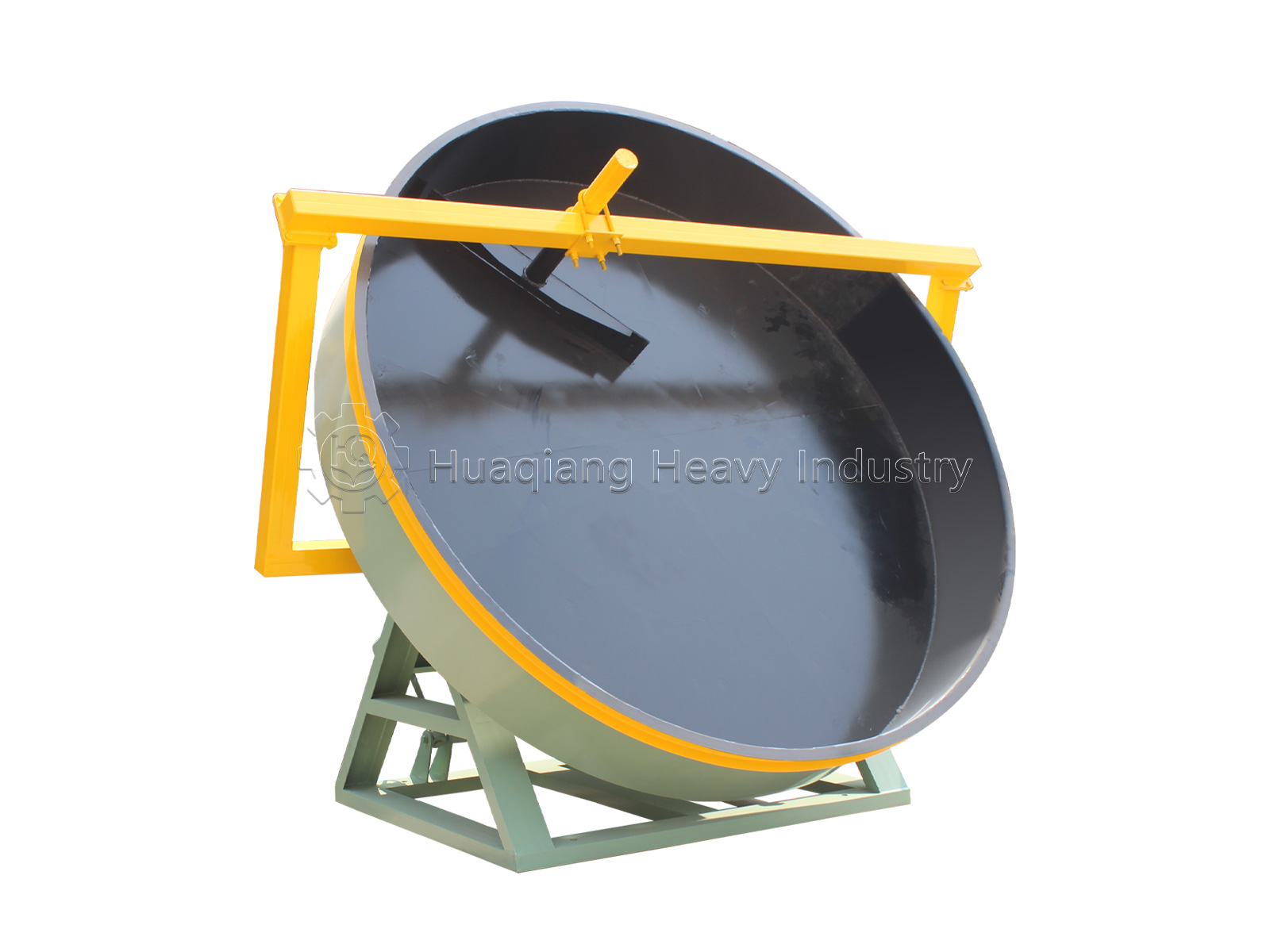

The essence of the disc granulator lies in its ingenious mechanical design. The main motor drives the reducer through a pulley and belt system, which then rotates the pinion gear. This pinion meshes with a large gear fixed at the end of the adjustment plate, transmitting power to the main shaft. The entire disc is mounted on this shaft, supported by the sturdy adjustment plate.

When materials are fed into the rotating disc, the real magic begins. With the help of spray devices, powder materials gradually aggregate into uniform pellets under the combined action of centrifugal force and binding agents, much like rolling snowballs. The disc's tilt angle and rotation speed are meticulously calibrated to ensure each pellet achieves perfect sphericity and consistent size.

To prevent material adhesion that could affect efficiency, an automatic cleaning device is ingeniously installed at the top of the disc. This thoughtful design not only ensures stable continuous production but also significantly extends the equipment's service life. With the motor running continuously, materials can be fed uninterruptedly, enabling truly continuous mass production.

The true advantage of disc granulators lies in their perfect marriage of simple principles and precision engineering. By optimizing every rotation parameter and mechanical interaction, this equipment can operate 24/7, meeting modern industry's demand for continuous, automated production. Whether for chemical raw materials or fertilizer production, disc granulators consistently deliver satisfactory results.