2025-09-01

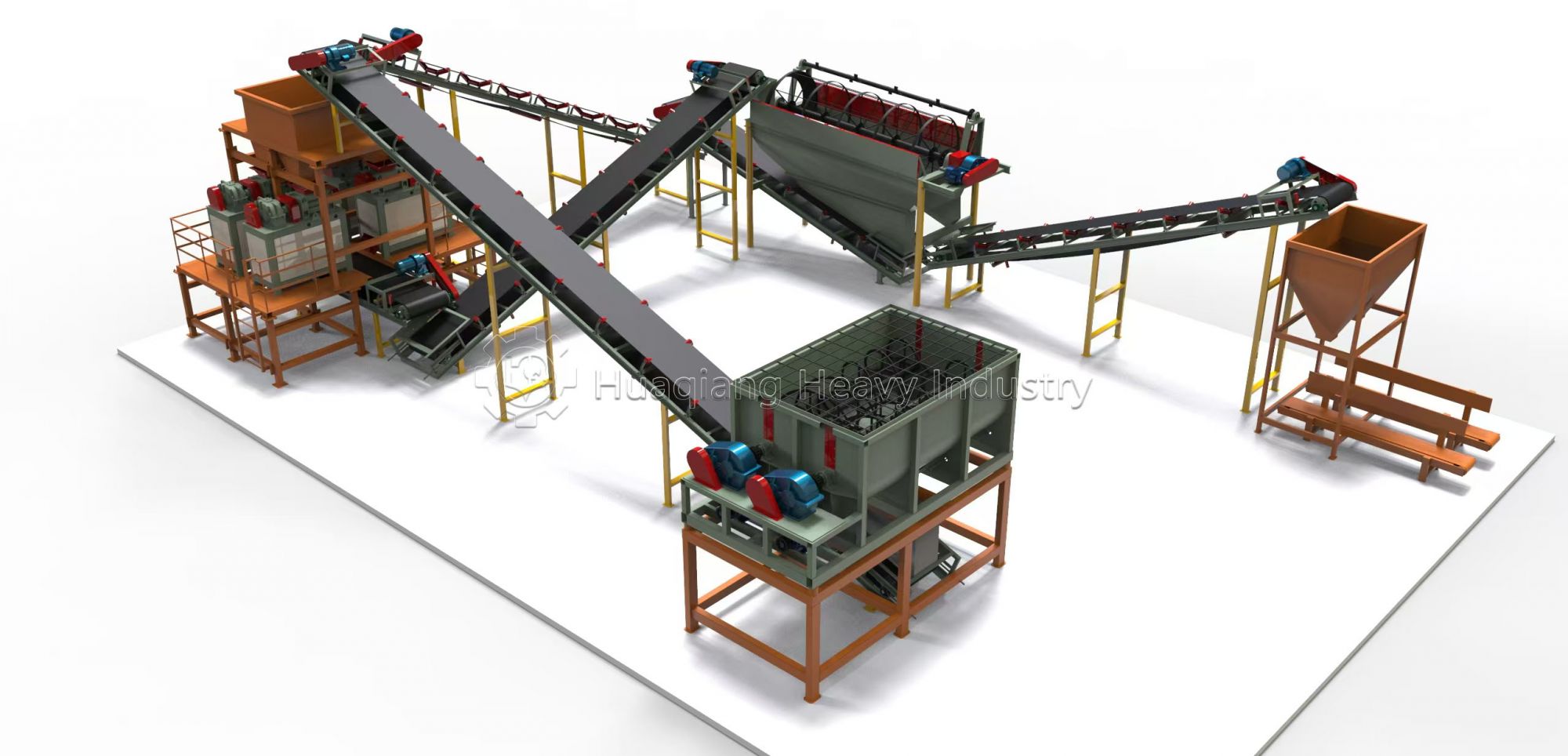

Raw materials such as urea, ammonium phosphate, and potassium chloride are elevated and conveyed into storage bins. The complexity of the mixing system depends on the fertilizer formula, but accuracy is always key.

This is where the real magic happens. A specialized fertilizer compaction machine, also known as a roller press granulator, exerts tremendous pressure on the mixed powder. As the material passes between two counter-rotating rollers, it’s compressed into a solid plate. The pressure builds, then releases, forming dense sheets ready for the next stage.

The compacted plates are pre-crushed and screened into desired particle sizes. Fine particles are recycled back into the mix, while oversized granules are crushed again. Proper selection of crushers and screens is crucial for economic efficiency.

Finally, the granules are polished in a rotating drum to smooth edges. Anti-dust and anti-caking agents are added to ensure a clean, free-flowing final product. The result? High-quality, uniform fertilizer granules ranging between 1-4mm.

For single-component fertilizers like granular potassium or ammonium sulfate, the process is even simpler—requiring less equipment and lower investment. Thanks to the efficiency of the fertilizer compaction machine, producing high-quality granules has never been easier!