In modern agricultural production, how to scientifically configure the

npk fertilizer production line?

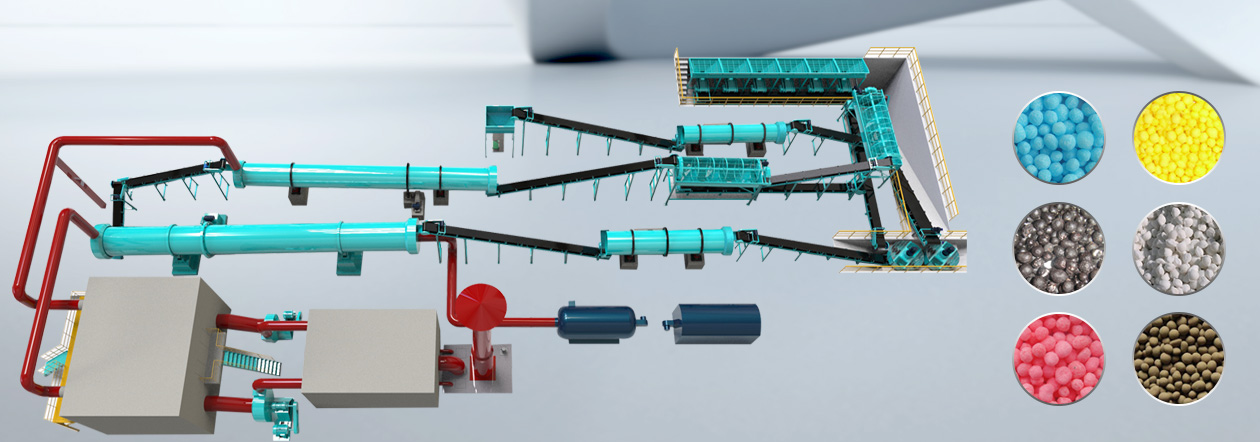

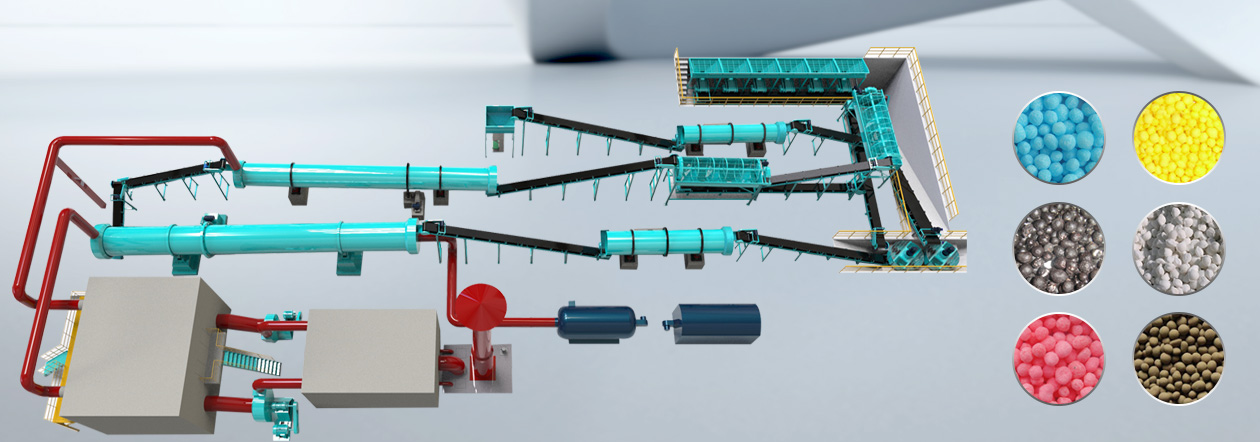

1. Raw material storage and transportation. The nitrogen, phosphorus and potassium compound fertilizer production line should be equipped with corresponding raw material storage facilities, such as warehouses, yards, etc., and equipped with conveying equipment, such as belt conveyors, bucket elevators, etc., to achieve rapid and stable transportation of raw materials.

2. Batching and mixing. The

npk fertilizer production line should select suitable batching machines and mixers to ensure uniform mixing of raw materials and improve product quality.

3. Granulation and drying. The mixed materials need to be granulated and dried. Granulation can be carried out by drum granulation or spray granulation, etc., according to product characteristics and market demand. Drying uses hot air circulation drying or boiling drying to remove moisture from the material and ensure product quality.

4. Cooling and screening. The temperature of the material after granulation and drying is high and needs to be cooled. Natural cooling or forced cooling can be used, depending on the actual situation. The cooled materials need to be screened to remove particles of unqualified particle size to ensure uniform product particle size.

5. Packaging and palletizing. Finally, the screened npk compound fertilizers need to be packaged and palletized. Packaging can be done by automatic packaging machines or manual packaging, and palletizing can be done by forklifts or palletizing robots to improve production efficiency.

The above is an introduction to the

npk fertilizer production line. If you want to know more about fertilizer production, please contact Huaqiang Heavy Industry.