The

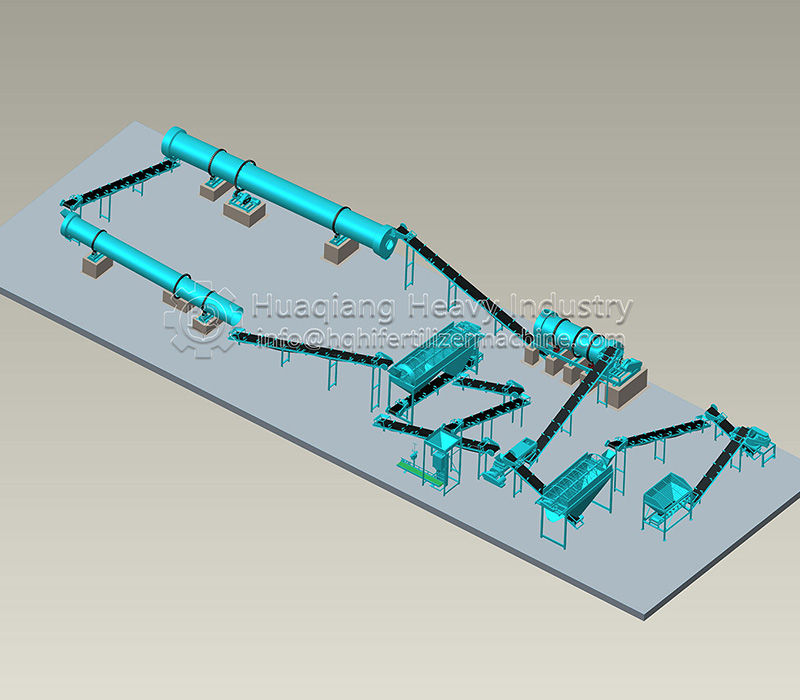

organic fertilizer production line has many links and involves many fertilizer equipment, and there are many potential risks. So, in the process of using the organic fertilizer production line, what aspects of daily inspection and maintenance do we need to do?

1. Daily inspection

Equipment operation status inspection: Before starting the machine every day, a comprehensive inspection of the

organic fertilizer production line equipment should be carried out to ensure that the equipment is in normal condition. The inspection content includes whether the key components such as motors, reducers, bearings, etc. are operating normally, and whether there are abnormal sounds or vibrations.

Lubrication inspection: Regularly check the lubrication system of the equipment to ensure that each lubrication point is fully lubricated. For key parts, such as bearings, chains, etc., lubricating oil or grease should be added regularly to reduce wear and friction resistance.

2. Regular maintenance

Cleaning and maintenance: Clean the organic fertilizer production line equipment regularly to remove dust, impurities and oil stains on the surface of the equipment. Especially for exposed parts, such as motors, reducers, etc., special attention should be paid to cleaning to prevent oil accumulation and corrosion.

Fastening maintenance: Regularly check the fasteners of the equipment, such as screws, nuts, etc., to ensure that they are fastened reliably. For loose or detached fasteners, replace or tighten them in time to prevent equipment failure during operation.

Replace worn parts: For easily worn parts, such as bearings, chains, etc., check their wear regularly. When the wear reaches a certain level, replace new parts in time to ensure the normal operation of the equipment.