2025-07-28

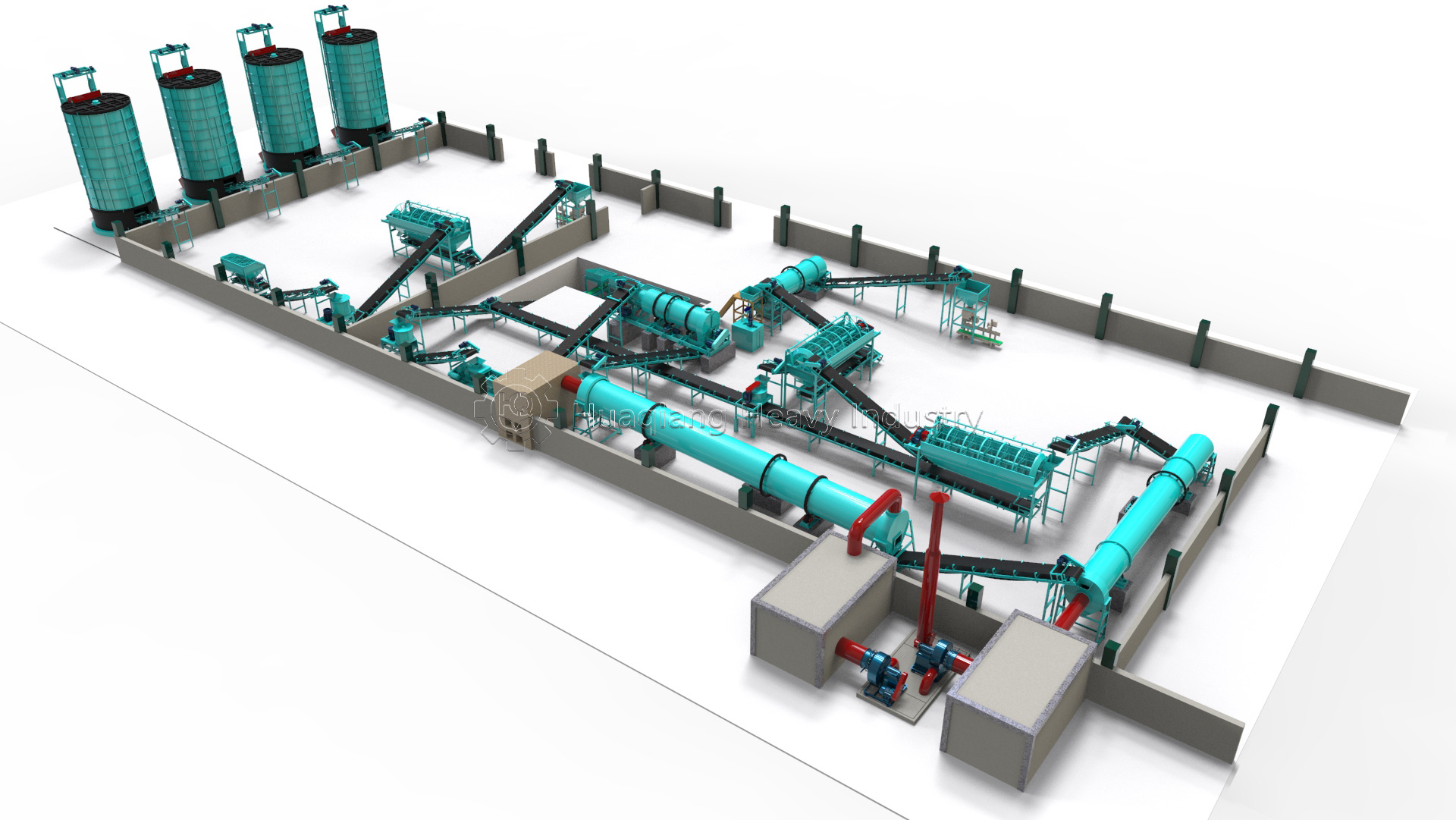

The bio-organic fertilizer production line typically consists of several key equipment, among which the "drum granulator" is one of the most important. A complete production line includes:

· Fermentation equipment (for aerobic fermentation of organic materials)

· Crusher (for raw material pretreatment)

· Mixer (for raw material proportioning and mixing)

· Granulator (core forming equipment, such as drum granulator)

· Dryer (to remove excess moisture)

· Cooler (to reduce particle temperature)

· Screening machine (for grading qualified products)

· Packaging machine (for finished product packaging)

Figure: typical bio-organic fertilizer production line

The drum granulator is a key equipment in bio-organic fertilizer production. It agglomerates powdered raw materials into granules through the centrifugal force of the rotating drum and the friction between materials. This equipment is particularly suitable for organic material granulation and has the following advantages:

· Large processing capacity, suitable for large-scale production

· High granulation rate with uniform shape

· Simple operation and easy maintenance

· Adaptable to various organic raw material formulations

The "bio fertilizer manufacturing process" is closely related to equipment selection. The typical process includes:

|

Process Step |

Main Equipment |

Key Control Parameters |

|

Raw Material Pretreatment |

Crusher, Mixer |

Material particle size, moisture content |

|

Fermentation |

Fermentation tank/Turner |

Temperature, humidity, C/N ratio |

|

Granulation |

Drum granulator |

Drum rotation speed, inclination angle, moisture |

|

Drying & Cooling |

Dryer, Cooler |

Temperature, residence time |

|

Screening & Packaging |

Screening machine, Packaging machine |

Particle specification, packaging weight |

When selecting bio-organic fertilizer equipment, the following factors should be considered:

1. Raw Material Characteristics: Different organic materials have varying physical and chemical properties

2. Production Scale: Different needs between small farms and large factories

3. Product Requirements: Quality standards such as particle size and strength

4. Investment Budget: Balance between equipment price and operating costs

5. Environmental Requirements: Waste gas and water treatment capacity

As the core equipment, the selection of drum granulator directly affects product quality and production efficiency. Modern organic fertilizer equipment is developing towards automation, intelligence and environmental protection, providing better technical support for sustainable agriculture.