2025-07-25

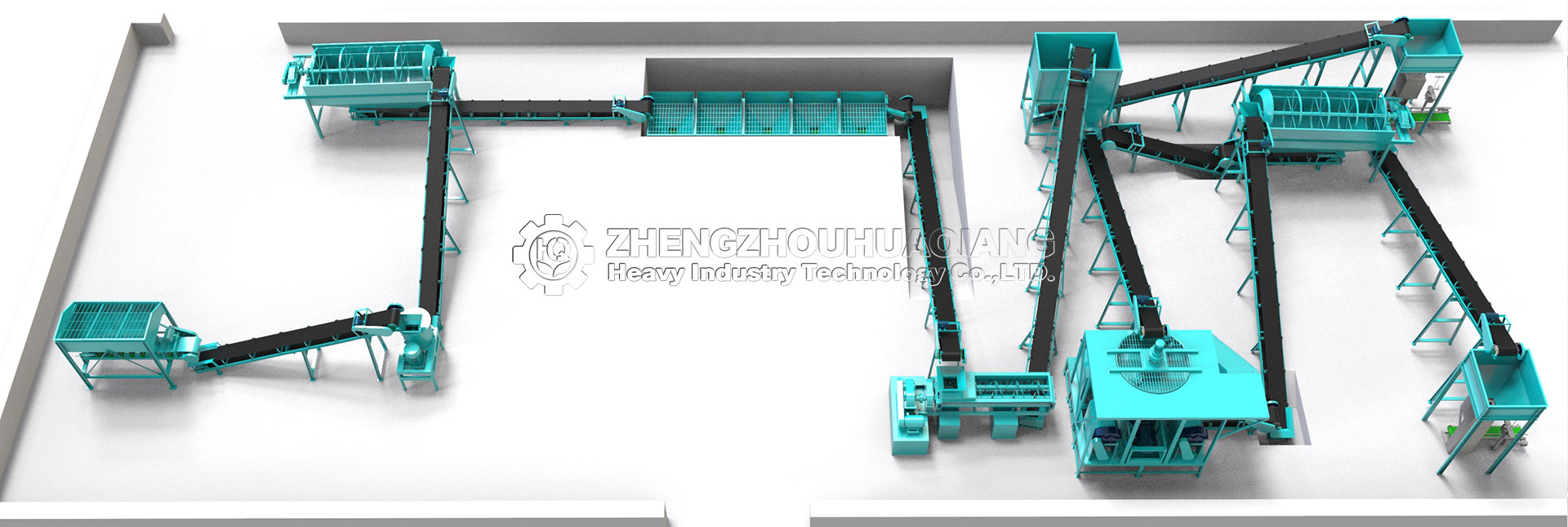

The rotary drum granulator plays a pivotal role in modern NPK fertilizer production lines by efficiently combining the key NPK manufacturing process steps - mixing raw materials, granulation, drying, and cooling - into a continuous automated system. This technology revolutionizes NPK production by transforming powdered nitrogen (N), phosphorus (P), and potassium (K) components into uniform, high-quality granules with improved nutrient consistency, physical properties, and application efficiency compared to traditional methods.

Compared to traditional granulation equipment, rotary drum granulators feature a unique rotating drum design that can increase production efficiency by over 40%. Their continuous operation capability makes mass production effortless, with single-unit daily output reaching 50-300 tons.

The carefully designed baffle system inside the drum ensures thorough material mixing, while precisely controlled tilt angles and rotation speeds perfectly balance granule formation and drying processes. Particularly noteworthy is the equipment's temperature control accuracy of ±3°C during operation, which is crucial for maintaining fertilizer nutrients.

The rotary drum granulator is truly the "Transformer" of the fertilizer world:

· Organic fertilizers: Perfectly processes various organic wastes

· Compound fertilizers: Uniformly mixes multiple nutrients

· BB fertilizers: Produces precision blended fertilizers

· Bio-fertilizers: Gently handles raw materials containing active strains

With simple adjustments to drum rotation speed and tilt angle, the same equipment can process various raw materials from powders to slurries, producing uniform granules of 2-8mm.

Modern rotary drum granulators incorporate numerous user-friendly features:

· Modular structure reduces maintenance time by 60%

· Wear-resistant liners extend service life by over 5 years

· Intelligent control system enables one-touch start/stop and parameter adjustment

· Energy-saving design reduces power consumption by 25-30%

With growing global demand for efficient agriculture and sustainable production, rotary drum granulators, with their excellent adaptability, reliability, and cost-effectiveness, have become indispensable core equipment for fertilizer producers. They not only improve production efficiency but also ensure product quality consistency, providing strong technical support for modern agricultural development.