2025-09-24

The operation of this exceptional fertilizer machine begins with the raw material pretreatment stage. Livestock and poultry manure first undergoes solid-liquid separation to remove excess moisture, reducing water content to below 70%; straw is crushed to 10-20 cm lengths; industrial waste requires removal of impurities such as metals and plastics.

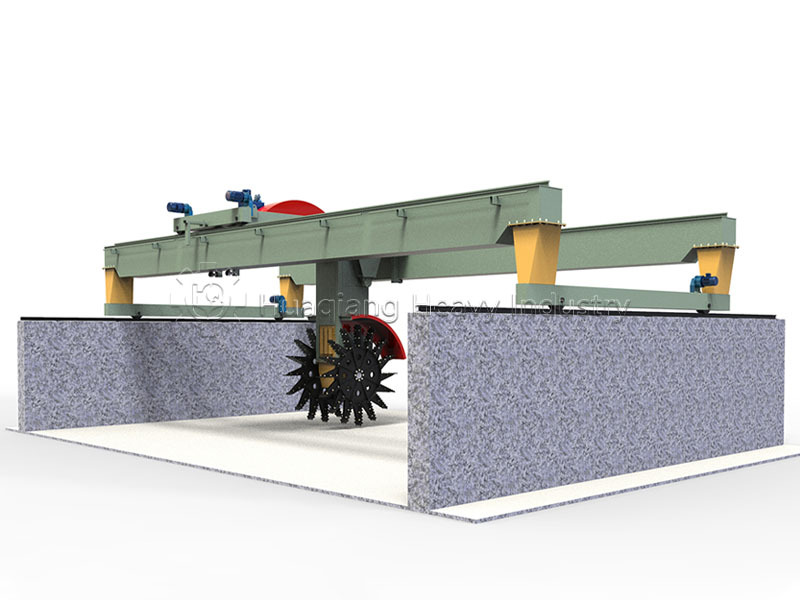

The pretreated materials are stacked into large windrows, with a 3-5 meter passage between windrows allowing this large fertilizer production machine to operate efficiently. The real magic begins here—the high-speed rotating wheel drives turning teeth to toss materials upward from the bottom.

Throughout the fermentation cycle, this highly efficient compost fertilizer machine demonstrates its true value. The entire fermentation cycle lasts 20-30 days, with a single unit processing 500-1000 tons of material daily, effectively eliminating pathogens and promoting humus formation.

When the material temperature drops to near ambient temperature, color turns dark brown, texture becomes loose, with no noticeable odor but a light earthy aroma, it indicates complete compost maturity. The mature material can be transported to subsequent processing areas, ultimately becoming high-quality organic fertilizer products.