2025-09-23

Choosing the right granulator is crucial for efficient fertilizer production, which depends on whether you're producing NPK compound fertilizers or bulk blends (BB). The unique characteristics of each product require different equipment, impacting cost, precision, and yield.

.jpg)

For NPK fertilizer production, granulators must handle chemical reactions and heat-induced agglomeration. Drum granulators dominate this role: a rotating cylindrical drum tumbles a moist mixture of urea, phosphate, and potash, which undergoes chemical reactions during the tumbling process. Friction and surface tension bind the material into spherical granules ranging in size from 2 to 5 mm. This system is well-suited for large-scale production (over 10,000 tons per year) and produces granules with a uniform distribution of nutrients—critical for NPK's fixed-ratio formulations.

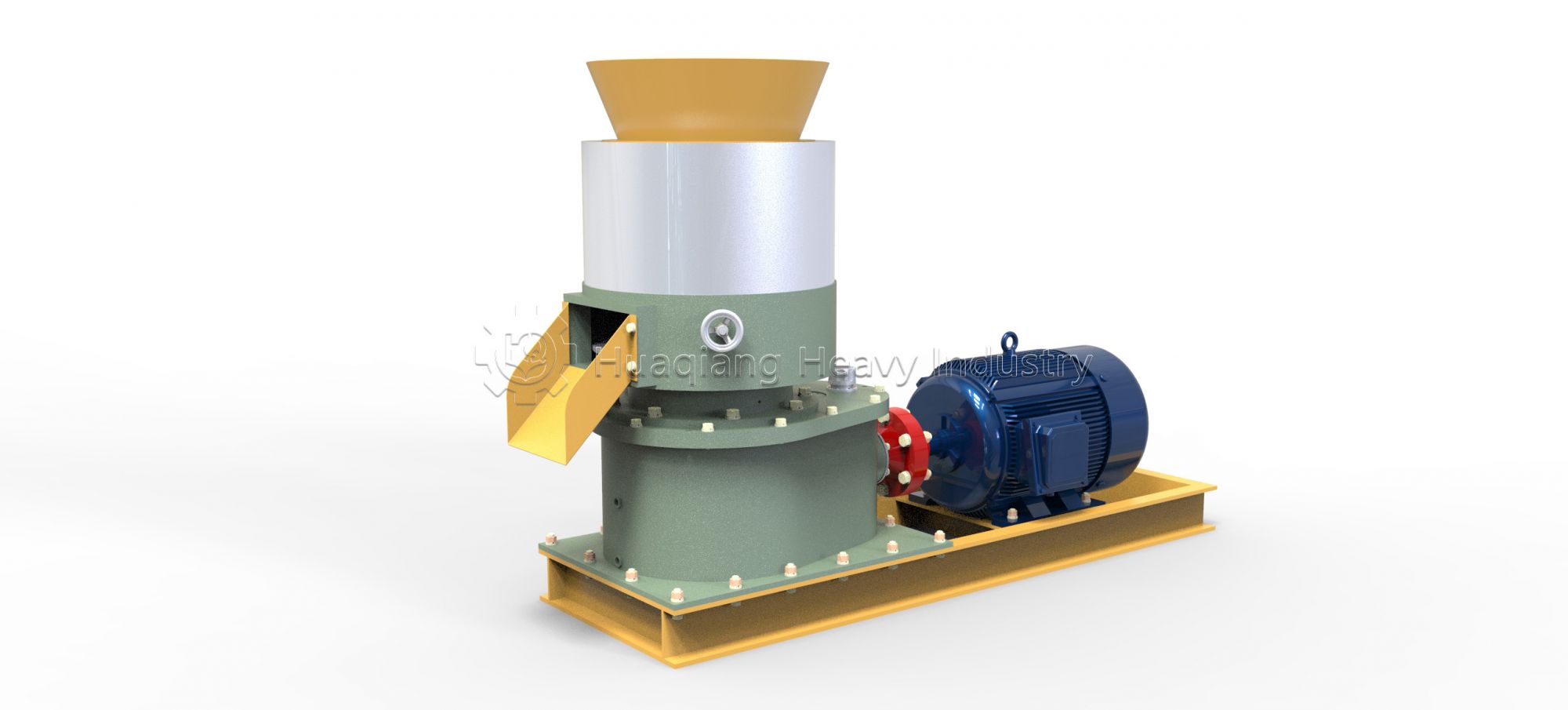

For smaller-scale NPK operations, extrusion granulators are a popular fertilizer production machine choice. This type of fertilizer compaction machine works by forcing a moist nutrient paste through a die under high pressure, creating dense, continuous rods. These rods are subsequently crushed and screened into irregularly shaped granules. A key advantage of this method is its low-temperature operation, which perfectly preserves heat-sensitive additives like trace elements. It also offers superior control over final granule size. The trade-off, however, is a lower overall production yield compared to high-capacity drum granulation systems, making extrusion an ideal solution for specialized, lower-volume production runs.

By contrast, BB fertilizers rarely require traditional granulation—the core process involves blending preformed single-nutrient granules (urea, diammonium phosphate, and potash). However, two specialized machines play a supporting role. Ribbon blenders ensure uniform mixing of these different granules, preventing segregation that could affect nutrient ratios. To enhance functionality (for example, with slow-release BB fertilizers), disc granulators can apply coatings (such as sulfur or polymers) to the blended granules, extending their shelf life and improving nutrient release.

Key differences in operational requirements dictate equipment selection. NPK granulators require robust heat and humidity control: drum systems often integrate steam injectors to maintain optimal reaction conditions, while extruders require precise humidity control to avoid clogging. In contrast, BB mixing equipment prioritizes gentle handling to prevent granule breakage and uses anti-static features to reduce dust.

Cost considerations also differ. A basic drum granulator for NPK production costs 30-50% more than a ribbon mixer for BB fertilizer, reflecting its complex engineering. However, NPK's higher profit margins generally justify this investment. For startups, BB's lower equipment costs (and simpler operation) offer a gentler entry point—although scaling up requires upgrading mixing capacity to avoid bottlenecks.

In short, NPK requires a heavy-duty granulator designed for chemical reactions, while BB relies on precision mixing and optional coating equipment. Matching the granulator to the fertilizer type ensures efficiency, product quality, and long-term profitability.