In addition to the common livestock and poultry manure such as cow dung, pig manure, chicken manure, there are many other organic wastes that can also be made into organic fertilizers. So, what is

organic fertilizer manufacturing process using waste as raw materials?

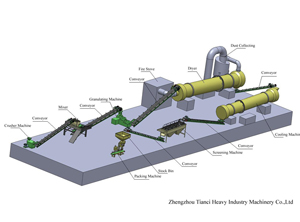

The first step of organic fertilizer manufacturing process: raw material collection. First, collect organic waste, such as livestock and poultry manure, straw, mushroom residue, etc., as the main raw material for preparing organic fertilizer.

The second step of

organic fertilizer manufacturing process: pretreatment. Pretreatment of raw materials, including removal of impurities, crushing into appropriate particle size and humidity, etc., to improve fermentation efficiency and subsequent crushing effect.

The third step of organic fertilizer manufacturing process: fermentation. The raw materials are evenly distributed in the fermentation site through the turning device, and regular turning and ventilation are carried out to promote the reproduction and fermentation process of microorganisms.

The fourth step of organic fertilizer manufacturing process: crushing and screening. The fermented organic waste needs to be crushed and screened for subsequent granulation and packaging.

The fifth step of

organic fertilizer manufacturing process: granulation and packaging. The organic waste is crushed to a suitable particle size, and screened into organic fertilizers of different specifications, and granulated fertilizers are made through a granulating device and packaged.

The above is an introduction to the organic fertilizer manufacturing process. If you want to know more about organic fertilizer production, organic fertilizer equipment, etc., please contact Huaqiang Heavy Industry.