Speaking of organic fertilizer production lines, many people know that a granulator is needed to make raw materials into particles. The same is to shape the fertilizer, so why is there a

ball shaping machine with a granulator?

Organic fertilizer and compound fertilizer have different shapes and sizes when they are initially formed into fertilizer particles. On the one hand, the fertilizer is uniform in size and the particles are round, which looks beautiful and convenient for sale. Moreover, in the actual fertilization process, the uniformity of fertilizer particles makes it easier for the soil to absorb fertilizer. The organic fertilizer production line is equipped with a series of ball shaping machines such as

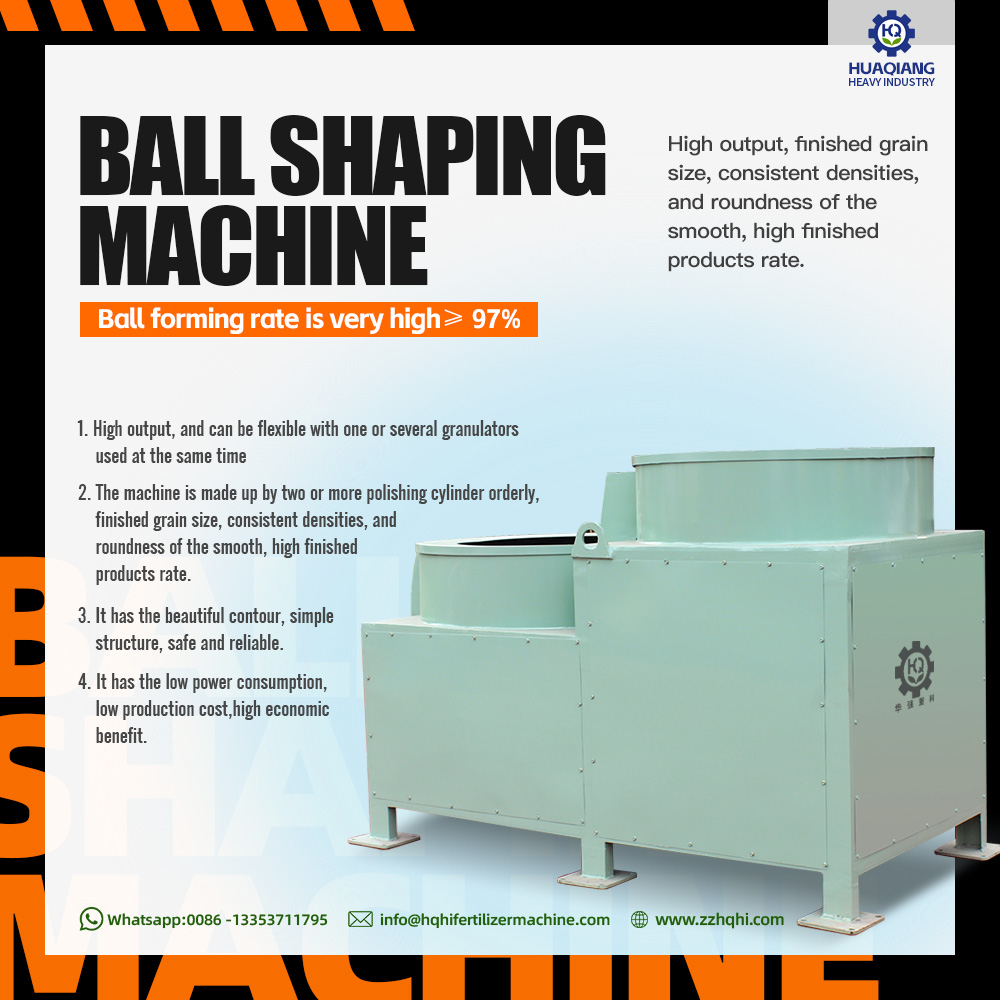

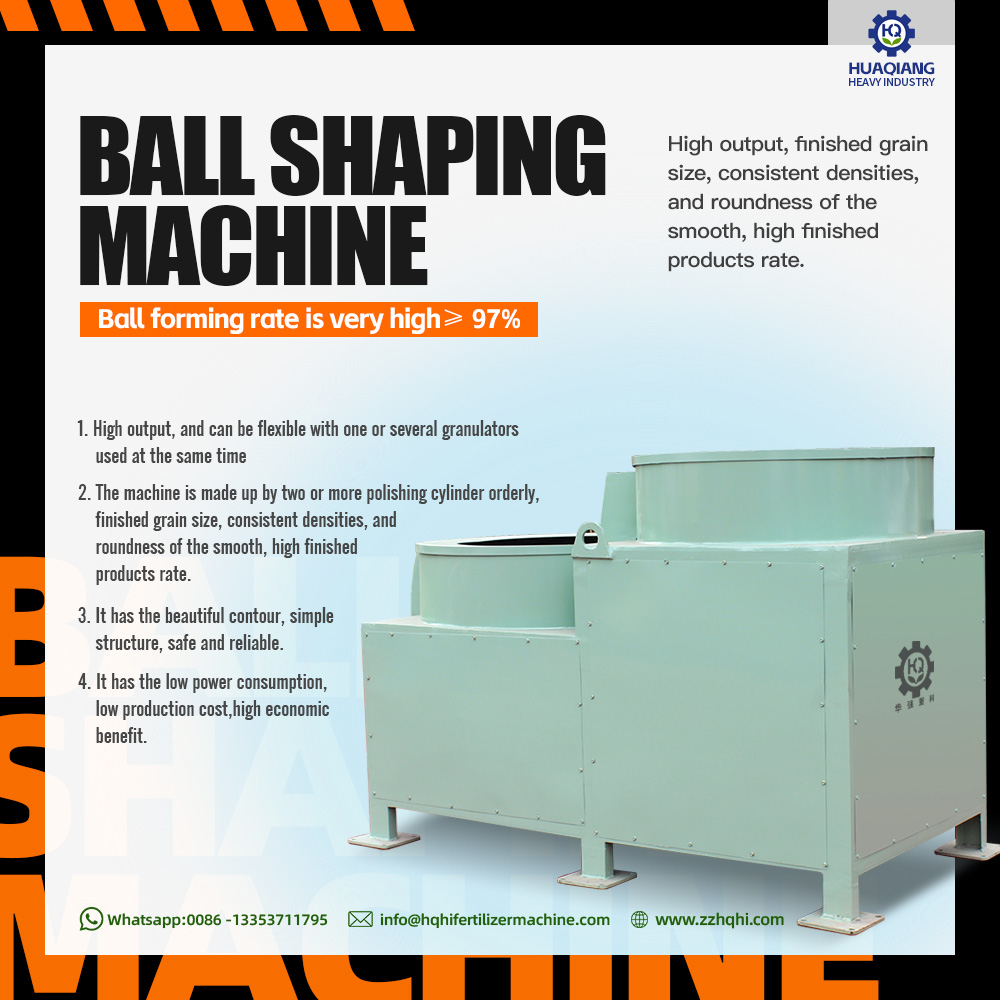

organic fertilizer ball shaping machines and compound fertilizer ball shaping machines. The ball shaping machine is a rounding device configured on the basis of the organic fertilizer granulator, which makes the cylindrical particles roll into balls at one time. The rounding machine has the advantages of no return, high ball formation rate, good strength, beautiful and practical.

The ball shaping machine is a device used for the production and grinding of organic fertilizer particles. It can evenly grind the organic fertilizer particles through the rounding process, making the organic fertilizer more round and beautiful.

It has a unique design, simple structure and is easy to operate. Secondly, the internal structure of the

ball shaping machine is made of high-quality steel material, which is wear-resistant and durable, and can maintain a good use condition for a long time! The above is why the organic fertilizer production line is equipped with a rounding machine. If you also need organic fertilizer equipment and don’t know how to build an organic fertilizer production line, you can contact Huaqiang Heavy Industry.