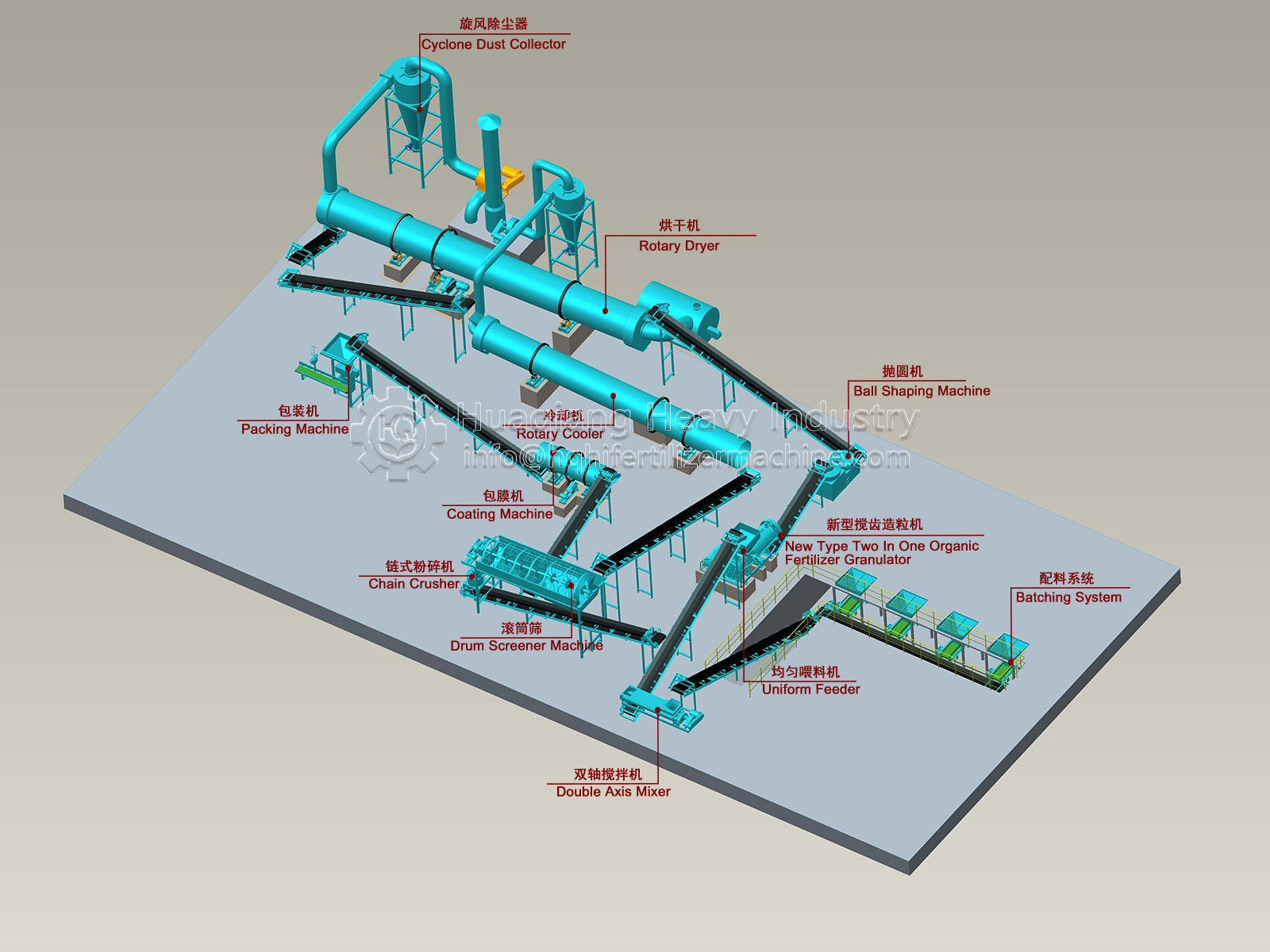

Ingredients: Mix cow dung, mushroom residue, mushroom bran, wood ash and other raw materials in proportion.

Mixing and mixing: Use a mixer to fully mix the ingredients and add a certain proportion of water at the same time.

Granulation: The mixed materials are granulated by a granulator.

Drying: The granular materials are sent to the dryer for drying to a certain degree of dryness.

Cooling: The dried granular materials are cooled by a cooler to ensure product quality and storage period.

Screening: The cooled granular materials are screened according to certain specifications by a screening machine and stored in categories.

Packaging: Use a packaging machine to package the finished organic fertilizer for sale and use.

Site selection: The production line should be built close to the raw material production area to save transportation costs.

Equipment selection: Suitable equipment should be selected according to the production scale and process requirements to ensure production efficiency and product quality.

Environmental protection requirements: Pay attention to environmental protection during the production process to avoid pollution to the surrounding environment.

Quality management: A complete quality management system should be established to ensure that product quality meets relevant standards.

The above are the main links of the

organic fertilizer production line. In actual operation, some farms build their own organic fertilizer production lines only for their own use and do not need to sell them. In this case, a powdered organic fertilizer production line can be considered to save the granulation link.