A trough compost turner is a device specifically designed for fermentation processing. By turning and stirring materials within the fermentation tank, it creates a suitable environment for fermentation. It is widely used in fields such as organic fertilizer production. Its core working principle is to use the turning teeth on the mechanical arm to perform a reciprocating motion within the fermentation tank, turning the accumulated materials, allowing them to fully contact the air. This simultaneously regulates the temperature and humidity of the materials, promotes microbial activity, and accelerates the composting and fermentation of the materials.

This equipment adopts a trough structure design, which can realize continuous fermentation operations. Compared with traditional manual turning or ground composting methods, the fermentation efficiency is greatly improved, the fermentation cycle is significantly shortened, and it can effectively control odor and pollution during the fermentation process. It is one of the key equipment for large-scale organic fertilizer production.

What raw materials can be fermented by the trough compost turning machine?

The trough compost turning machine has strong adaptability to fermentation raw materials and can process a variety of organic wastes, as follows:

Livestock and poultry manure

This includes chicken, pig, cow, and sheep manure, which are rich in organic matter and nutrients like nitrogen, phosphorus, and potassium, making them excellent raw materials for producing organic fertilizer. The trough compost turning machine turns the manure to fully ferment it, killing pathogens, insect eggs, and weed seeds, while also eliminating odor.

Crop straw

Corn straw, wheat straw, rice straw, etc. contain a large amount of cellulose, hemicellulose and lignin, which can be converted into organic matter in organic fertilizer through fermentation. The trough compost turning machine can evenly mix the straw with other raw materials to promote the decomposition and maturity of the straw.

Edible mushroom residue

The residue from mushroom cultivation, rich in mycelium and underutilized nutrients, is a high-quality organic fermentation raw material. After fermentation in a compost turning machine, it can be made into highly effective organic fertilizer.

Industrial organic waste

These wastes include organic by-products generated during industrial production processes, such as wine dregs, vinegar dregs, sugar residues, and oil residues. These wastes contain certain organic matter and nutrients, and can be recycled after fermentation by a trough compost turning machine.

Municipal sludge

Sludge generated by municipal sewage treatment plants contains a large amount of organic matter, but may also contain harmful substances such as heavy metals. It must undergo rigorous testing and treatment before it can be used as fermentation raw material. The trough compost turning machine can fully ferment the sludge, reduce its moisture content, and stabilize its properties.

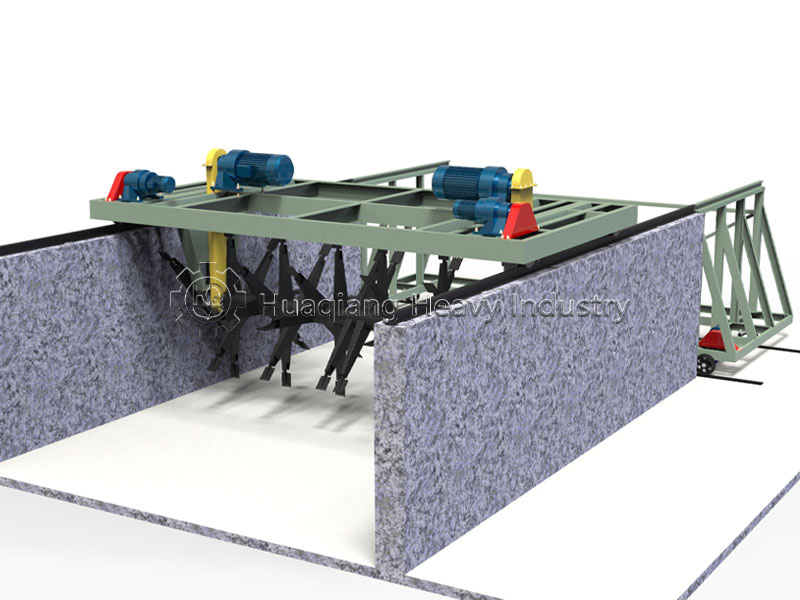

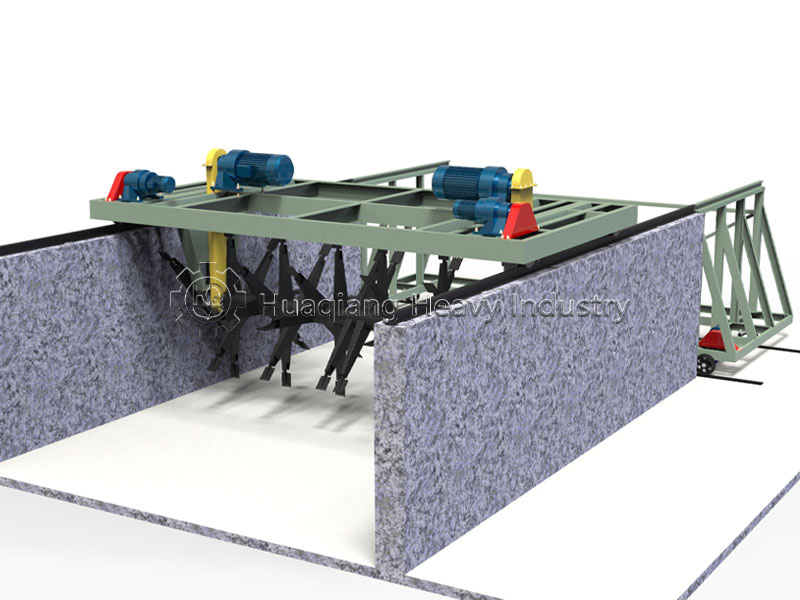

Equipment composition of trough type compost turning machine

The trough compost turning machine consists of several key components that work together to ensure the smooth progress of the compost turning operation. The specific components are as follows:

frame:

Traveling mechanism:

Compost turning mechanism:

hydraulic system:

Electronic control system:

fermentation tank:

How does a trough compost turning machine compost organic fertilizer raw materials?

The process of composting organic fertilizer raw materials with a trough-type compost turning machine is a systematic fermentation process that requires strict control of each link.

The specific steps are as follows:

Raw material pretreatment:

Raw materials into the tank:

Turning and fermentation:

During the fermentation process, the frequency of compost turning should be determined based on the temperature of the material. Generally, the first turning is performed when the material temperature reaches 60-70°C. Thereafter, turning is performed every 1-3 days. The specific turning frequency can be adjusted based on the fermentation progress. The entire fermentation cycle generally lasts 15-30 days.

Maturity judgment:

| Simple Compost Turning Machine | ||||

|

Model

|

Main Motor | Walking Motor | Lifting Motor | Mobile Car Motor |

| FD3 | 7.5kw*2 | 1.5kw | / | 1.5Kw |

| FD4 | 11kw*2 | 1.5kw | / | 1.5Kw |

| FD5 | 15kw*2 | 2.2kw | 0.75kw | 1.5Kw |

| FDT3 | 7.5 kw*2 | 1.5kw | 0.75 kw | 1.5Kw |

| FDT4 | 11kw*2 | 1.5 kw | 0.75 kw | 1.5Kw |

| FDT5 | 15kw*2 | 2.2 kw | 0.75 kw | 1.5Kw |